742

Start cooking this BEER

So, a year ago in the Lipetsk region, Leo Tolstoy, an area in the floor with a remarkable extinct village called round, we had bought old and has been working for 5 years the school. The goal we set for ourselves, to build a school in the small recreation ground with its own brewery. The name given to our project Eco-base "Dubrava" I wish that the rest was pure, the products that we sell are edible and the beer that today we have finally begun to cook this.

So, what you need for this beer? Most importantly the desire and the soul of the brewer. For if to cook it with a clear conscience not regretting this component, it must succeed.

So here we go:

The base beer is barley malt, many manufacturers have long since learned to replace it with rice or corn grits, if not brew beer from concentrates. But this is not our way.

23 photo.

2.Granulirovanny hops

3.Special Saccharomyces cerevisiae

4.Konechno same brewery boiler

So they poured water into the pot and put it to warm at this time Fractions malt mill on a special, very large.

5. Mill

Like this:

6.

So water is warmed up and we fall asleep, our crushed malt in the brewery boiler.

7.

The control cabinet with the running program. After cooking, we should get a drink called wort. The cooking process is faster and includes several time intervals with a certain temperature. We start with 32 degrees and bring to 78

Cooking in progress, in time heating boiler of our crushed malt all proteins, sugars and other delicacies enter our drink. Starch is converted to sugar well, etc. etc.

9.

So the program is completed, it is time to proceed to the next stage.

10

To start doing iodine test to check that all the starch is turned into sugar

So there is no starch, ie iodine has not changed its color. Otherwise it would be blue.

12.

With a special food pumps begin to distill the resulting substance very similar to the thin gruel

13.

The filter-chan, which must remain our crushed malt, it is called brewer's grain.

14

So in the filter vat went our substance

15.

Boiler forlornly empty, but ready to fight.

16.

So we wait for 10-15 minutes to our grains settled in the filter pan and slowly, gradually begin to pump filtered through a pellet wort back into the boiler.

17.

This is what is left in the filter vat. Brewers' grains.

18.

That's what we pumped into the boiler, pure sweet wort.

19.

To measure the initial density prior to boiling, and are very pleased density of about 17.5-18, it is very good beer is dense with rich flavor.

20.

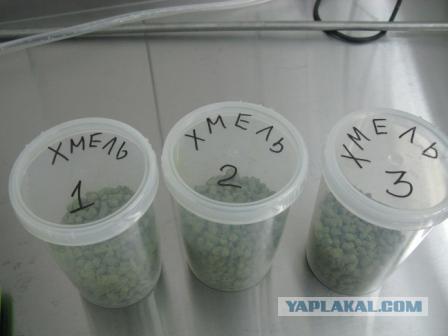

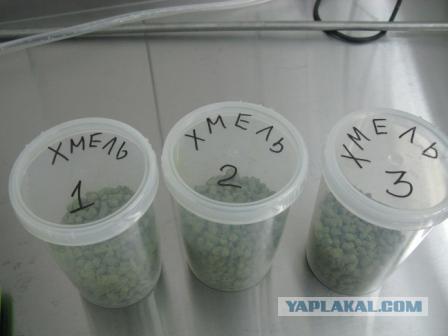

Now we proceed to the boiling wort, approximately 90 minutes. During boiling, the hops are added to the wort, but not all at once but in three portions. In the beginning, middle and end.

While there is wort boiling vat of my filter.

22.

Posted in [mergetime] 1394647207 [/ mergetime]

Friends, unfortunately had to go and leave my camera brewers. TO BE CONTINUED ...

You can break.

Source:

So, what you need for this beer? Most importantly the desire and the soul of the brewer. For if to cook it with a clear conscience not regretting this component, it must succeed.

So here we go:

The base beer is barley malt, many manufacturers have long since learned to replace it with rice or corn grits, if not brew beer from concentrates. But this is not our way.

23 photo.

2.Granulirovanny hops

3.Special Saccharomyces cerevisiae

4.Konechno same brewery boiler

So they poured water into the pot and put it to warm at this time Fractions malt mill on a special, very large.

5. Mill

Like this:

6.

So water is warmed up and we fall asleep, our crushed malt in the brewery boiler.

7.

The control cabinet with the running program. After cooking, we should get a drink called wort. The cooking process is faster and includes several time intervals with a certain temperature. We start with 32 degrees and bring to 78

Cooking in progress, in time heating boiler of our crushed malt all proteins, sugars and other delicacies enter our drink. Starch is converted to sugar well, etc. etc.

9.

So the program is completed, it is time to proceed to the next stage.

10

To start doing iodine test to check that all the starch is turned into sugar

So there is no starch, ie iodine has not changed its color. Otherwise it would be blue.

12.

With a special food pumps begin to distill the resulting substance very similar to the thin gruel

13.

The filter-chan, which must remain our crushed malt, it is called brewer's grain.

14

So in the filter vat went our substance

15.

Boiler forlornly empty, but ready to fight.

16.

So we wait for 10-15 minutes to our grains settled in the filter pan and slowly, gradually begin to pump filtered through a pellet wort back into the boiler.

17.

This is what is left in the filter vat. Brewers' grains.

18.

That's what we pumped into the boiler, pure sweet wort.

19.

To measure the initial density prior to boiling, and are very pleased density of about 17.5-18, it is very good beer is dense with rich flavor.

20.

Now we proceed to the boiling wort, approximately 90 minutes. During boiling, the hops are added to the wort, but not all at once but in three portions. In the beginning, middle and end.

While there is wort boiling vat of my filter.

22.

Posted in [mergetime] 1394647207 [/ mergetime]

Friends, unfortunately had to go and leave my camera brewers. TO BE CONTINUED ...

You can break.

Source: