830

Excursion to the brewery Krušovice

The author writes Ilya Chernikov:

Today my story is about the beer, and I'll show you some photos from the Prague plant Krušovice. The plant is located in the village Krušovice (near the city of Rakovnik, Central Bohemian Region).

1. Well, let's start a small excursion into the world of beer!

Let me remind you that beer - low-alcohol drink, alcoholic fermentation produced using malt wort brewer's yeast, usually with the addition of hops.

Beer - the third most popular beverage in the world (after water and tea) and the most popular alcoholic beverage in the world.

In general, the production of beer is as follows: Preparation of beer wort, fermenting wort brewer's yeast, secondary fermentation.

Well, and then I'll tell us more about the process.

2. If the plant has a small shop where you can always buy beer and various souvenirs. If you look closely, you can see that a bottle of beer costs 12 kroons, which is our money 12 1 * 7 = 20 rubles. While a bottle of Baltika №7 has cost at least 30 rubles. Quality, I think you can not compare

3. Van "happiness»

4. The territory of the plant

5. The territory of the plant "scattered" historical objects

6. In this room there are kettles for brewing beer.

But before you start to brew beer, you need to prepare the source material. Barley is the main raw material for beer.

Assembled from a field of barley is soaked in water and waiting for it will absorb moisture. The water was then decanted and the grain constant agitation, begin to dry. Already at this stage it is in the grain enzymes and enzymes begin to convert kramhal in sahar.Zatem to stop the process, barley roasted.

The resulting product is called malt in English - Malt, and the process - malting.

7. Coat the Brewers. But returning to the beer brewing process, it should be noted that, depending on the temperature of the roasting barley malt obtained by the various colors. The color of malt during cooking greatly affect the color of beer is prepared. Sprouted and roasted malt treated in special machines to remove germs. They are fed to livestock.

8. At the brewery, the malt is pulverized in special crushers, and not just crumble, and as it opens each grain in half. It is important to provide access to karhmalu and are very damaging enzymes in the grain.

9. The crushed malt is filled with water and begin to heat. During heating, the enzymes being processed beans starch into sugar. Moreover, the process of heating occurs in steps, with pauses. In the grain group contains various enzymes. And these pauses - the optimum temperature for certain groups of enzymes. Ultimately, the maximum possible number of processed starch into soluble sugars.

10. The wort is filtered and pumped into the tank for boiling. In the process of boiling evaporated excess water, and there is sterilization of the wort. During this and hops are added. He gives the bitterness and aroma to beer and serves as a natural antibakteritsidom.

11. Of the cranes take to analyze the process of brewing beer in

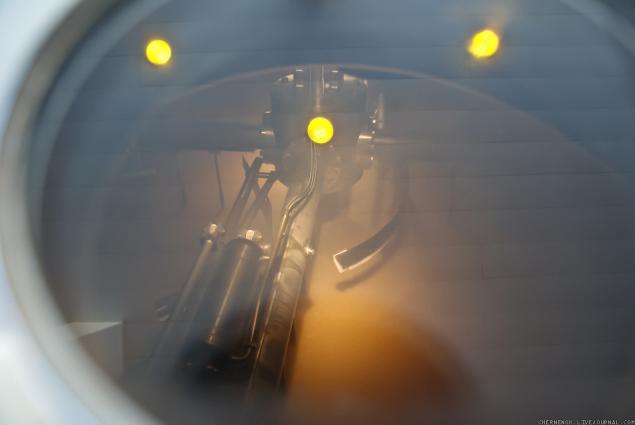

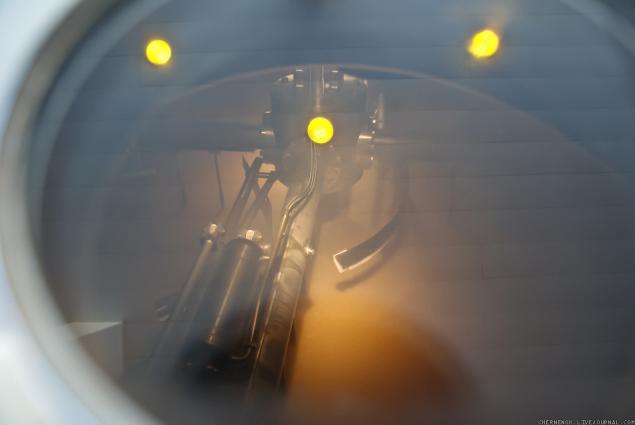

12. The purpose of these tanks, I do not know

13. On the territory of many areas where there are tanks or boxes and ready to ship products

14. Well, here we already find ourselves in a room, which houses the brewed beer. In the chilled wort added special brewer's yeast, which in the process of fermentation in the wort being processed sugars into alcohol. At this stage yeast fermentation is also situated in the must absorb oxygen and release carbon dioxide. At the end of fermentation the yeast is removed for reuse.

14. Well, here we already find ourselves in a room, which houses the brewed beer. In the chilled wort added special brewer's yeast, which in the process of fermentation in the wort being processed sugars into alcohol. At this stage yeast fermentation is also situated in the must absorb oxygen and release carbon dioxide. At the end of fermentation the yeast is removed for reuse.

15. Dobrazhivayut beer in metal tanks at 1-2 (C. The duration of fermentation is determined by the beer brand and may have a term of up 3-4 and even 6 months.

16. At all stages of beer production is carried out quality control

17. Again, an element of decor

Well, a few words about non-alcoholic beer!

Despite the name, in the non-alcoholic beer contains 0, 2-1, 0% alcohol, completely get rid of it fails. There are several technologies for the production of non-alcoholic beer. Alcohol contained in the conventional beer removed using vacuum distillation (using a low boiling point alcohol), and by dialysis (membrane method). Also, get rid of alcohol by fermentation suppression, with special yeast maltose is not converted into alcohol, a process of fermentation is stopped by lowering the temperature. The membrane is considered the best method, because it uses the traditional production technology and taste of the beer the least different from the usual. But because of the low content of alcohol taste of non-alcoholic beer is obtained with any other technology, as alcohol has a significant impact on the taste of the beer. Due to the more complex production technology of non-alcoholic beer, its cost is higher than usual. In soft beer contains phytoestrogens and fusel oil (all positive and negative properties of beer are just not alcohol intoxication occurs due to low alcohol content).

18. In such fields growing hops. Distance between the posts is exactly the width of the tractor that he could go and harvest. Unfortunately, when we drove past the fields, the harvest has been collected

via chernenok

Source:

Today my story is about the beer, and I'll show you some photos from the Prague plant Krušovice. The plant is located in the village Krušovice (near the city of Rakovnik, Central Bohemian Region).

1. Well, let's start a small excursion into the world of beer!

Let me remind you that beer - low-alcohol drink, alcoholic fermentation produced using malt wort brewer's yeast, usually with the addition of hops.

Beer - the third most popular beverage in the world (after water and tea) and the most popular alcoholic beverage in the world.

In general, the production of beer is as follows: Preparation of beer wort, fermenting wort brewer's yeast, secondary fermentation.

Well, and then I'll tell us more about the process.

2. If the plant has a small shop where you can always buy beer and various souvenirs. If you look closely, you can see that a bottle of beer costs 12 kroons, which is our money 12 1 * 7 = 20 rubles. While a bottle of Baltika №7 has cost at least 30 rubles. Quality, I think you can not compare

3. Van "happiness»

4. The territory of the plant

5. The territory of the plant "scattered" historical objects

6. In this room there are kettles for brewing beer.

But before you start to brew beer, you need to prepare the source material. Barley is the main raw material for beer.

Assembled from a field of barley is soaked in water and waiting for it will absorb moisture. The water was then decanted and the grain constant agitation, begin to dry. Already at this stage it is in the grain enzymes and enzymes begin to convert kramhal in sahar.Zatem to stop the process, barley roasted.

The resulting product is called malt in English - Malt, and the process - malting.

7. Coat the Brewers. But returning to the beer brewing process, it should be noted that, depending on the temperature of the roasting barley malt obtained by the various colors. The color of malt during cooking greatly affect the color of beer is prepared. Sprouted and roasted malt treated in special machines to remove germs. They are fed to livestock.

8. At the brewery, the malt is pulverized in special crushers, and not just crumble, and as it opens each grain in half. It is important to provide access to karhmalu and are very damaging enzymes in the grain.

9. The crushed malt is filled with water and begin to heat. During heating, the enzymes being processed beans starch into sugar. Moreover, the process of heating occurs in steps, with pauses. In the grain group contains various enzymes. And these pauses - the optimum temperature for certain groups of enzymes. Ultimately, the maximum possible number of processed starch into soluble sugars.

10. The wort is filtered and pumped into the tank for boiling. In the process of boiling evaporated excess water, and there is sterilization of the wort. During this and hops are added. He gives the bitterness and aroma to beer and serves as a natural antibakteritsidom.

11. Of the cranes take to analyze the process of brewing beer in

12. The purpose of these tanks, I do not know

13. On the territory of many areas where there are tanks or boxes and ready to ship products

14. Well, here we already find ourselves in a room, which houses the brewed beer. In the chilled wort added special brewer's yeast, which in the process of fermentation in the wort being processed sugars into alcohol. At this stage yeast fermentation is also situated in the must absorb oxygen and release carbon dioxide. At the end of fermentation the yeast is removed for reuse.

14. Well, here we already find ourselves in a room, which houses the brewed beer. In the chilled wort added special brewer's yeast, which in the process of fermentation in the wort being processed sugars into alcohol. At this stage yeast fermentation is also situated in the must absorb oxygen and release carbon dioxide. At the end of fermentation the yeast is removed for reuse.

15. Dobrazhivayut beer in metal tanks at 1-2 (C. The duration of fermentation is determined by the beer brand and may have a term of up 3-4 and even 6 months.

16. At all stages of beer production is carried out quality control

17. Again, an element of decor

Well, a few words about non-alcoholic beer!

Despite the name, in the non-alcoholic beer contains 0, 2-1, 0% alcohol, completely get rid of it fails. There are several technologies for the production of non-alcoholic beer. Alcohol contained in the conventional beer removed using vacuum distillation (using a low boiling point alcohol), and by dialysis (membrane method). Also, get rid of alcohol by fermentation suppression, with special yeast maltose is not converted into alcohol, a process of fermentation is stopped by lowering the temperature. The membrane is considered the best method, because it uses the traditional production technology and taste of the beer the least different from the usual. But because of the low content of alcohol taste of non-alcoholic beer is obtained with any other technology, as alcohol has a significant impact on the taste of the beer. Due to the more complex production technology of non-alcoholic beer, its cost is higher than usual. In soft beer contains phytoestrogens and fusel oil (all positive and negative properties of beer are just not alcohol intoxication occurs due to low alcohol content).

18. In such fields growing hops. Distance between the posts is exactly the width of the tractor that he could go and harvest. Unfortunately, when we drove past the fields, the harvest has been collected

via chernenok

Source: