1216

Production chains at the factory Red Anchor

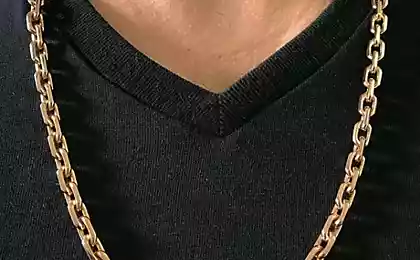

In Nizhny Novgorod is Russia's Red Anchor Chain Factory which was founded in 1898, due to increased demand for the ship circuit. But the plant for ship chains did not stop, and now make a chain for various purposes: from tire protection to kompletyuschih for mining equipment.

Now the plant is divided into three main workshops: big chains, medium and small. Process and product manufacturing stages are about the same, but the larger the chain, the longer and bigger it looks. Let's start with the average shop chains. Feature medium size is, that the machines do everything ourselves, but from machine to machine products need to be transported by hand.

The first stage of manufacture of the circuit is feeding material into the machine, which cut off a piece of the desired length and bent to form a unit, and then connected with other parts.

The second step is provarkoy gap. Without these links in the chain under load simply disconnected. The third step is checked, that is, the chain is loaded on the machine, which pulls it in accordance with the allowable weight. If one of the links does not stand up, then this is the link expands, removed, added a new and again boil. Then again to check.

After successful validation, the circuit goes into an oven for heat treatment. This step gives more strength products.

Then comes the big shop chains. The main application of such circuits - it ships and mines. Compared to the average, are used in large volumes of work of employees.

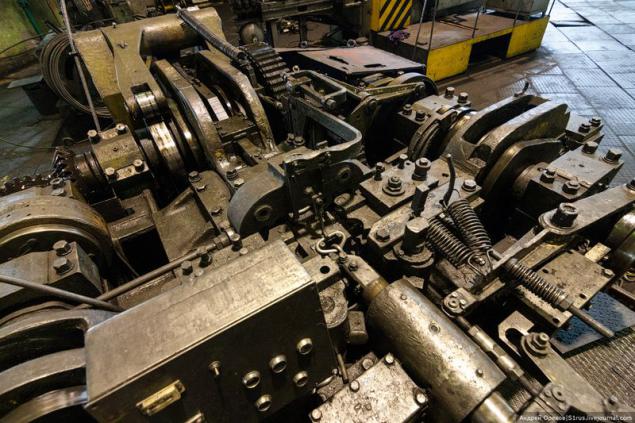

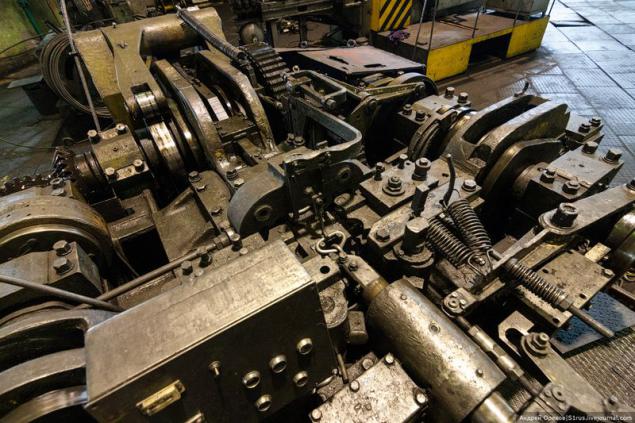

The so-called "carousel". Old machine, but it takes just the first two stages. For its operation need four employees, each of which does its part.

When the job is in the center of the "carousel" are formed here are a handful of a few hundred kilograms.

Some of the chain immediately after joining and welding units are sent by crane into the tank, which begins to vibrate and rotate. Thus, there is a smoothing element.

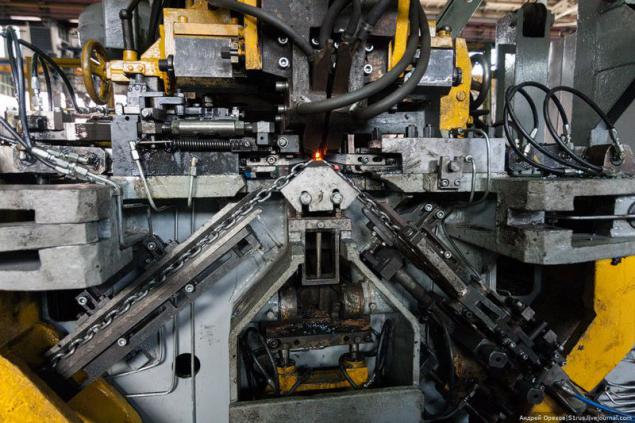

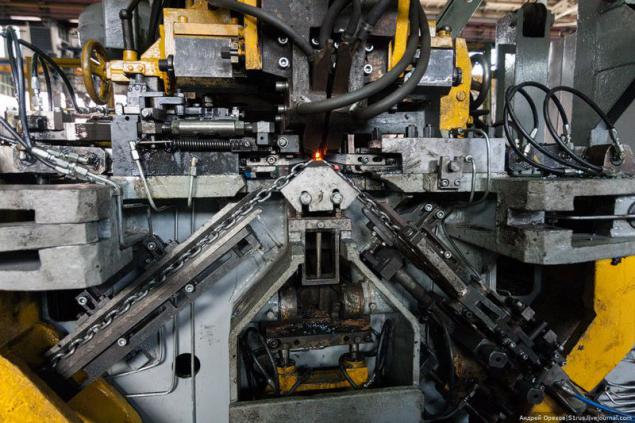

On Red anchor quietly trying to update the machines, because some already for 60-40 years, but the new prices are measured in millions of euros - it's a little difficult to quick replacement. The picture automatically "Carousel" from the German company ESAB. It is fully automated, and the worker simply controls the process.

The machine in 1990 - is considered to be fairly new.

Such a long tape is used for mine production. The fact that this circuit has a clearly defined length, which allows error of 2 millimeters.

100 year old press.

This is a horizontal hydraulic press, that he checks the strength of the big chains. By the way, it is also very old.

And in an oven for heat treatment! Medium chain transported on trucks, and then only lifts.

Moving to the small shop chains. Its peculiarity is that almost everything is done automatically. And this is achieved entirely Nenov equipment.

For example, because of the light weight products are the first two stages of continuous chain, and work simply monitors and corrects the process.

Served raw material, and the output can only send in the oven.

From the size of the process does not change, only the speed and scale of production.

But the plant still places where you need to connect the chain links manually. This young boy and it is engaged. By the way, the plant is almost no old people. Most up to 40 years. There is also a training department, which takes the children after schools.

For every taste and color.

The new equipment is put. When I was in almost every shop was going or standing for several new machines.

In addition to workshops with chains, there are forging press, held a variety of additional products or fixtures.

It's simple. Heat the blank under pressure making the desired shape, and then cut the excess pieces. The photograph inefficient furnace, because a large number of tempo is simply lost, so the shop has a new, but it is still used.

Year 1912. Work.

Actually here. The new furnace heats, and work gives her the desired shape.

Another portion of forging shop. Due to the very old equipment work is rare. At one time there was the head of a man who hung on poles pictures of the best workers, had his alley, "the best people».

Also, the plant has a brand new shop, where only the freshest machines. Basically, there's all sorts of cut blanks.

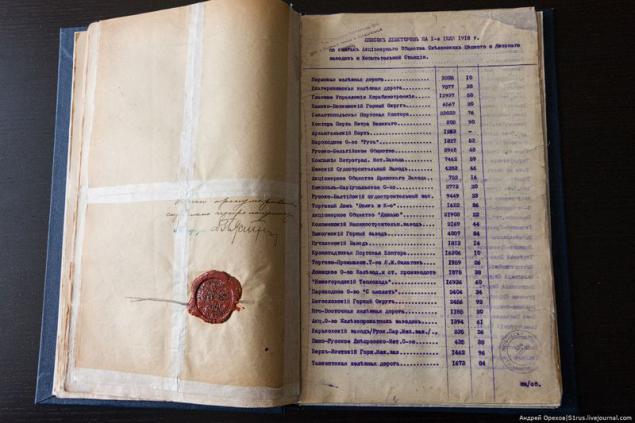

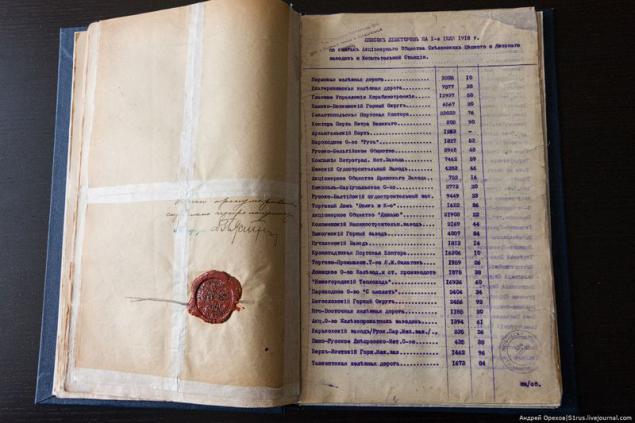

After a walk through the production looked to the director, who was "his." He showed us a book, found in the archives. It is relevant to 1918

Under storage allocated a separate huge building.

Source: s1rus.livejournal.com

Now the plant is divided into three main workshops: big chains, medium and small. Process and product manufacturing stages are about the same, but the larger the chain, the longer and bigger it looks. Let's start with the average shop chains. Feature medium size is, that the machines do everything ourselves, but from machine to machine products need to be transported by hand.

The first stage of manufacture of the circuit is feeding material into the machine, which cut off a piece of the desired length and bent to form a unit, and then connected with other parts.

The second step is provarkoy gap. Without these links in the chain under load simply disconnected. The third step is checked, that is, the chain is loaded on the machine, which pulls it in accordance with the allowable weight. If one of the links does not stand up, then this is the link expands, removed, added a new and again boil. Then again to check.

After successful validation, the circuit goes into an oven for heat treatment. This step gives more strength products.

Then comes the big shop chains. The main application of such circuits - it ships and mines. Compared to the average, are used in large volumes of work of employees.

The so-called "carousel". Old machine, but it takes just the first two stages. For its operation need four employees, each of which does its part.

When the job is in the center of the "carousel" are formed here are a handful of a few hundred kilograms.

Some of the chain immediately after joining and welding units are sent by crane into the tank, which begins to vibrate and rotate. Thus, there is a smoothing element.

On Red anchor quietly trying to update the machines, because some already for 60-40 years, but the new prices are measured in millions of euros - it's a little difficult to quick replacement. The picture automatically "Carousel" from the German company ESAB. It is fully automated, and the worker simply controls the process.

The machine in 1990 - is considered to be fairly new.

Such a long tape is used for mine production. The fact that this circuit has a clearly defined length, which allows error of 2 millimeters.

100 year old press.

This is a horizontal hydraulic press, that he checks the strength of the big chains. By the way, it is also very old.

And in an oven for heat treatment! Medium chain transported on trucks, and then only lifts.

Moving to the small shop chains. Its peculiarity is that almost everything is done automatically. And this is achieved entirely Nenov equipment.

For example, because of the light weight products are the first two stages of continuous chain, and work simply monitors and corrects the process.

Served raw material, and the output can only send in the oven.

From the size of the process does not change, only the speed and scale of production.

But the plant still places where you need to connect the chain links manually. This young boy and it is engaged. By the way, the plant is almost no old people. Most up to 40 years. There is also a training department, which takes the children after schools.

For every taste and color.

The new equipment is put. When I was in almost every shop was going or standing for several new machines.

In addition to workshops with chains, there are forging press, held a variety of additional products or fixtures.

It's simple. Heat the blank under pressure making the desired shape, and then cut the excess pieces. The photograph inefficient furnace, because a large number of tempo is simply lost, so the shop has a new, but it is still used.

Year 1912. Work.

Actually here. The new furnace heats, and work gives her the desired shape.

Another portion of forging shop. Due to the very old equipment work is rare. At one time there was the head of a man who hung on poles pictures of the best workers, had his alley, "the best people».

Also, the plant has a brand new shop, where only the freshest machines. Basically, there's all sorts of cut blanks.

After a walk through the production looked to the director, who was "his." He showed us a book, found in the archives. It is relevant to 1918

Under storage allocated a separate huge building.

Source: s1rus.livejournal.com