2397

Tver Carriage

Whenever you are struck on an interesting and large scale production, I am willing to be there for days, taking interesting shots, delving into the intricacies of production and technology. It's insanely fun.

It happened with the Tver Carriage Works. To them I arrived around 10 am, and had originally planned to finish in time for the presentation of the new trains. But where there! By two o'clock we had just finished shooting the shop, which produces components ... and after the presentation has finally begun the most important - the assembly shops. My accompanying obviously planned to get rid of the time - at 17:00, but, sorry to leave early from there is simply impossible. In the end, shooting ended at half past six, and even then there are still lots of things that could be see.

60 photos via livejournal.

And then - another problem. I photographed in the production of more than 1,000 personnel. Marriage, repeats and failed to throw out the angles at once. Incidentally, this 800-something frames to cart happened. And a place to save. :) Hundreds more is dropped after the second pass. And then begins a painstaking work, as the remaining 300 to select those that are needed for the post. This is hell, my friends, in fact. The fact that captured a very complex and multifaceted production, and I want to show everything. Some shots are necessary for the understanding of technical processes, and some are just beautiful. As a result, stung to 60 pieces. Excuse me, did not get smaller.

So, after a short introduction - Tver Carriage Works. The largest company in Russia and the CIS for the production of various types of passenger cars and accessories. The main supplier of cars for JSC "Russian Railways" (and his "daughter" - OJSC "FPC"). The company is part of the "Transmashholdinga».

Existing production facilities and technological capacities allow to simultaneously work on the production of several models of passenger cars, as well as different types of freight cars and cars of special purpose (in one shop was not allowed to shoot, said that there is going to something secret).

1. The factory was founded in 1898 by the French-Belgian joint stock company "Diehl and Bakalan" called "Upper Volga plant railway materials." In 1915 it was renamed in Tver Russian-Baltic Carriage Factory, and after nationalization (in 1918) - Tver Carriage Works. In the period from 1931 to 1990 was called Kalinin Carriage Works.

2. From the first years of the twentieth century, the factory began the era of the passenger carriages. In Tver, produced four-axle sleeping cars for Joint Stock Company "International Society of sleeping cars and high-speed European trains", as well as passenger cars of all four classes, the double-decker cars, service cars with living and sleeping compartment, passenger coaches for countries with hot climates. On a two-storey car archival photographs created on TVZ in 1905

3. The plant is a huge area of Tver, and in fact this is the only major operating company in this city. On the territory you can see buildings of different ages and types. For example, in the photo you can see the oldest building - wooden frame of the local water tower boiler. It costs as much to the XIX century.

4. But his tour, we start with a woodworking shop. Now, in a modern car, a tree is used very little, and almost before the whole car was made of wood. Tree, rather it wood board, which is currently used, is impregnated with special compounds from combustion and decay. Alas, this did not come immediately, and several large fires, and later tests showed that older cars were burned in just a few minutes. But it was. Now, the fire safety rules draconian and the manufacturer is obliged to follow them. Well equipment today is not what it used to, at least look at the CNC. Replaces up to 8 classic machines for woodworking. Details of any configuration processes in minutes, highest accuracy, which affects respectively on accuracy and speed of assembly of finished cars.

5. Now in this shop is made almost the entire insides of the car. As the material along with the plywood and timber stands FIRE plastic, aluminum profiles and other modern materials. But to preserve the historical name.

6. For example, if I am not mistaken, it's plastic lining interior panels. Install them in the car on the side walls over the glass panes.

7. Work on the superglue sticks Compartment door rubber seals. About half of the 12th in the morning, and he has spent so many tubes of glue.

8. Plant and spent conducting modernization of machine park. The enterprise can find a huge number of modern CNC machine tools.

9. The machine sawing simultaneously four metal profile, which later become part of the internal equipment of the car.

10. Now go through and see what makes the metal parts of the car of the future. For instance, this item has been obtained on the press. Precision bending clearly controlled goniometer.

11. This sheet metal after plasma cutting. Such installations factory three. There are 14 laser systems - for cutting sheet metal. In the foreground, there were cut side of the bogie frames. Further still some small things. Remains of the sheet after cutting will be shipped to the smelter. Again in operation. Generally the plant are very sensitive to metal waste, and everything is going to work again.

12. punching machines. Part of accessories and small items when their application amount is large, is not profitable to do with new technology (expensive and less efficient), so use this machine park. And next is old news very shaggy's. But in a completely operational condition. Decided to keep it in production as active monument. A kind of "player-coach".

13. The color of items is done on automatic powder coating line, but with mandatory visual inspection and touch-up hand sprayer complex surfaces.

14. According to the representative of the plant, even in the most successful year of great importance was given to health and used in the tools and materials. Honestly, with the move to believe weakly, but what I saw in the shops, it confirms.

15. Now it's time to make a frame for undercar trucks. First prepared sheets of metal joints are specially adapted and prihvatyvayut welding.

16. Next comes in automatic robot welder. It is with these machines many years ago started a global modernization of welding equipment. Inaccessible places boil manually.

17. Almost finished bogie frame. As the quality of the trolley and wheel sets - is the safety of passengers, the requirements for the quality - the highest. Moreover, the item is put on the personal stamp of all who worked with her. And who checked and controlled. All these data are then stored at all times of operation of the trolley and wheel sets.

18. In the foreground is a pile of bogie frames for underground car 81-760 / 761 "Oka". TIZ makes them for Metrovagonmash.

19. Very smart machine finishing bogie frame. Special sensors are checked dimensions and axis. From these new coordinates axes are measured and drilled holes are processed edge. Ie for example, if the bracket has been welded offset couple of millimeters, the machine recognizes this and the hole will be drilled in the bracket, regardless of the desired location.

20. Now the production of wheel sets. Axis itself machined in place at railway wheels that come on TVZ with different plants, including with Vyksa Steel Works, bore mounting hole (wheel hub).

21. Nozzle wheel axle. There are hot and cold method of attachment. It is used cold. The inner diameter of the hole in the wheel slightly smaller than the outer diameter of the axle. And the press is mounted on the wheel axle with a predetermined force. Fixed by a special process monitoring device with graphic recording charts pressing.

22. Ready wheelsets are sent to the assembly trolleys.

23. Finished truck new design passenger car with disc brakes.

24. And this is the old, familiar to all construction truck. It is now produced on a nearby plant in Tver.

25. Press for hot forging. On it with the help of special stamps are obtained from parts of complex shape preforms in a preheated hot gas furnaces.

26. Now go through the foundry. On this photo you can see a nondescript literally technical revolution in the foundry business. If you need to cast a simple item without cavities inside, it's simple. But if the item is complex and inside the cavity and are channels? There are two options. In the first case, the inside of the flask is placed inside a wax model. It gives the internal structure and pouring the metal melts and flows. But it can do simple things. And if complicated? Then the internal cavities formed using sand models. Previously, tamp them by hand, and on the day of one person could make a dozen, since the work is very laborious, requires high precision and everything manually. Who makes the car model sand. The result of her work - in the photo. Once a minute and a half, two pops sand model. And then, after setting the items on the sand shaker model breaks down and poured out the details.

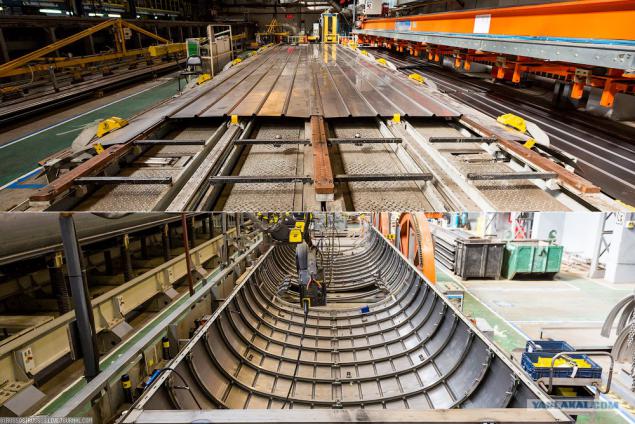

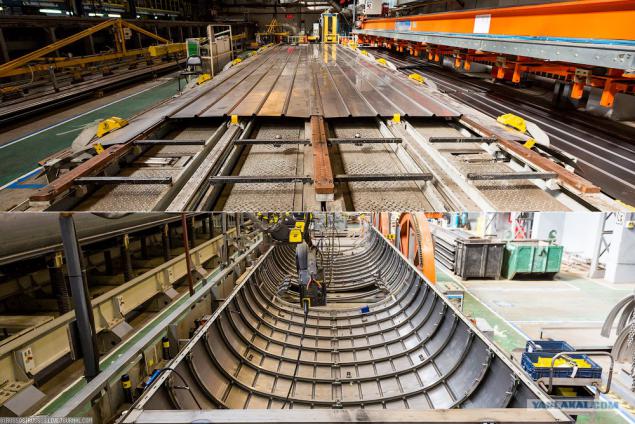

27. The lower part of the flask with the established model of sand.

28. Issuance of iron.

29. The bucket is small enough as it takes a certain temperature to ensure the quality of metal casting - a large number of metal do not have time to pour into the flask, the cooling time is limited

30. manages to pour a few flasks and again go for the grant of iron.

31. Complete details of the foundry and surface treatment.

32. Now go look at the body assembly. First on special stocks welded frame of the car. Install and undercar equipment pave communication.

33. In parallel with the assembly frame body on a special line of cars manufactured sidewall. Assembly and welding process is automated, conducted with minimal human intervention.

34. Roof Sheathing first welded in flat form, and then flipped her on a special stand is attached to a semicircular shape. Arc welded and the roof is taking shape and stiffness.

35. Finally, all parts of the body (frame, sidewalls, end walls and roof) are connected together in the finished product - the foundation of the future of the car.

36. First comes potholder all incoming units and parts.

37. Further, all exterior horizontal seams species boil automatic settings. But the rest - hands.

38. All the car is almost ready. At least its skeleton. As you can see, there is no longer even a heater (or rather, the boiler) installed.

39. Wagon after applying thermal insulation coatings and flooring.

40. Next is essentially an ordinary assembly of large number of components and their verification. The photograph is an installation of water supply system. The wizard is ready to install a system of water disinfection.

41. The assembly is made on the positions - each run only certain actions. Then the carriage moves to the next position. Here they come already painted.

42. The car after the installation of almost all internal systems. Now it's time to set the partition and mount that in total will see passenger.

43. The plant is a major supplier of passenger cars for the "daughter" Railways - Federal Passenger Company. But the range of products the company is very extensive.

44. The new cars with seats and now include a train of constant formation, including specialties.

45. Full production car takes about 70 days. For double-decker cars, the figure is about 100 days. This is the period of manufacture of the first part to the finished car. In car assembly shop directly on the assembly of the finished product on the average car spends 12 days.

46. The main (left) serial line occupy wagons for Railways. On average, this time standing staff and dining cars. A right line is occupied by other projects. At the time of the shooting were sleeping cars for international traffic (dimension RIC) - a joint project of TIZ and Siemens.

47. wagons for the railways of Kazakhstan.

48. Since 2008, for the needs of Russian Railways were delivered in 2800 razllichnyh cars. These new cars are a priority on the formation and renewal of firm and fast trains.

49. Normal compartment car, I will not show you, and so many photos. But the presence of the socket in the compartment is very pleasing.

50. This lift for disabled staff car.

51. Special coupe and a toilet for them is only in this car. See how to make a broadening of passage to stroller could pass.

52. Now all of a body made of stainless steel. On the showground plant last serial car from ordinary carbon steel. Occasionally, if desired, the customer, the plant fills orders on cars on the old technology. But for the customer is a double edged sword. The difference in price of the car with a body made of stainless steel and normal - less than a million rubles. And the life of the car, stainless steel is 40 years against 28. By the way, learned to plant a secret which torments me long ago. You see at the end of the car show "mileage - 450". This means that the surface of the coupler and the buffer is fused additional metallic layer of high strength which provides carriages running without replacement of the wear parts is not less than 450 thousand. Km.

53. Two-storey car developed on the initiative of Russian Railways. About him so much already written that will not elaborate. On a photo the first prototype, the prototype on which the Company holds a test and develop the design and technology of this innovative product. To the credit of the plant must be said that this prototype is made in just 8 months from the start of the design - from the first line in the drawing. Few competitors, even in the world market, capable in such a short time to put on the production of a completely new product.

54. The first subway car, released at the factory. First, "Oka" collected in Mytishchi, then part of the order was sent to Tver. It was made. Who do TVZ only metro bogie frames.

55. Sleeping car dimensions RIC for international communications - a joint project of TIZ and Siemens commissioned by the Railways. Note the very broad surface of the end bellows.

56. At the train dwell. Coupe - in general, everything is familiar.

57. But as the door opens the compartment. Surprisingly, she mirror inside, but in the clear, it blocks a passage. Not very well, in my opinion, constructive solution, although the design was designed by one of the giants of the global car building - by «Siemens».

58. Each car has a shower.

59. washbasin under the table. But underneath there is no openers. :)

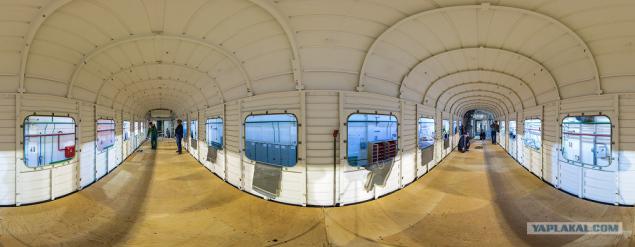

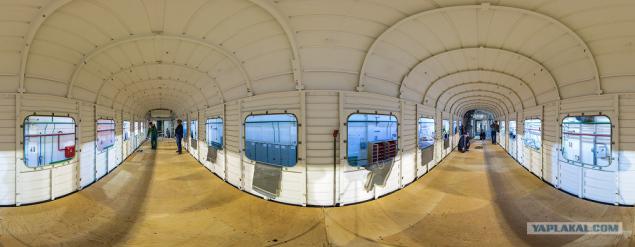

60. The Panorama Factory. Motor transport shop and railway line of finished products. Overs were painting shops, climate station for testing, central laboratory and a lot else. But already many photos. And until 2030 Railways will purchase 16, 5 thousand. Wagons at 774, 5 billion. Rubles, of which in the next three years - 2000.

It happened with the Tver Carriage Works. To them I arrived around 10 am, and had originally planned to finish in time for the presentation of the new trains. But where there! By two o'clock we had just finished shooting the shop, which produces components ... and after the presentation has finally begun the most important - the assembly shops. My accompanying obviously planned to get rid of the time - at 17:00, but, sorry to leave early from there is simply impossible. In the end, shooting ended at half past six, and even then there are still lots of things that could be see.

60 photos via livejournal.

And then - another problem. I photographed in the production of more than 1,000 personnel. Marriage, repeats and failed to throw out the angles at once. Incidentally, this 800-something frames to cart happened. And a place to save. :) Hundreds more is dropped after the second pass. And then begins a painstaking work, as the remaining 300 to select those that are needed for the post. This is hell, my friends, in fact. The fact that captured a very complex and multifaceted production, and I want to show everything. Some shots are necessary for the understanding of technical processes, and some are just beautiful. As a result, stung to 60 pieces. Excuse me, did not get smaller.

So, after a short introduction - Tver Carriage Works. The largest company in Russia and the CIS for the production of various types of passenger cars and accessories. The main supplier of cars for JSC "Russian Railways" (and his "daughter" - OJSC "FPC"). The company is part of the "Transmashholdinga».

Existing production facilities and technological capacities allow to simultaneously work on the production of several models of passenger cars, as well as different types of freight cars and cars of special purpose (in one shop was not allowed to shoot, said that there is going to something secret).

1. The factory was founded in 1898 by the French-Belgian joint stock company "Diehl and Bakalan" called "Upper Volga plant railway materials." In 1915 it was renamed in Tver Russian-Baltic Carriage Factory, and after nationalization (in 1918) - Tver Carriage Works. In the period from 1931 to 1990 was called Kalinin Carriage Works.

2. From the first years of the twentieth century, the factory began the era of the passenger carriages. In Tver, produced four-axle sleeping cars for Joint Stock Company "International Society of sleeping cars and high-speed European trains", as well as passenger cars of all four classes, the double-decker cars, service cars with living and sleeping compartment, passenger coaches for countries with hot climates. On a two-storey car archival photographs created on TVZ in 1905

3. The plant is a huge area of Tver, and in fact this is the only major operating company in this city. On the territory you can see buildings of different ages and types. For example, in the photo you can see the oldest building - wooden frame of the local water tower boiler. It costs as much to the XIX century.

4. But his tour, we start with a woodworking shop. Now, in a modern car, a tree is used very little, and almost before the whole car was made of wood. Tree, rather it wood board, which is currently used, is impregnated with special compounds from combustion and decay. Alas, this did not come immediately, and several large fires, and later tests showed that older cars were burned in just a few minutes. But it was. Now, the fire safety rules draconian and the manufacturer is obliged to follow them. Well equipment today is not what it used to, at least look at the CNC. Replaces up to 8 classic machines for woodworking. Details of any configuration processes in minutes, highest accuracy, which affects respectively on accuracy and speed of assembly of finished cars.

5. Now in this shop is made almost the entire insides of the car. As the material along with the plywood and timber stands FIRE plastic, aluminum profiles and other modern materials. But to preserve the historical name.

6. For example, if I am not mistaken, it's plastic lining interior panels. Install them in the car on the side walls over the glass panes.

7. Work on the superglue sticks Compartment door rubber seals. About half of the 12th in the morning, and he has spent so many tubes of glue.

8. Plant and spent conducting modernization of machine park. The enterprise can find a huge number of modern CNC machine tools.

9. The machine sawing simultaneously four metal profile, which later become part of the internal equipment of the car.

10. Now go through and see what makes the metal parts of the car of the future. For instance, this item has been obtained on the press. Precision bending clearly controlled goniometer.

11. This sheet metal after plasma cutting. Such installations factory three. There are 14 laser systems - for cutting sheet metal. In the foreground, there were cut side of the bogie frames. Further still some small things. Remains of the sheet after cutting will be shipped to the smelter. Again in operation. Generally the plant are very sensitive to metal waste, and everything is going to work again.

12. punching machines. Part of accessories and small items when their application amount is large, is not profitable to do with new technology (expensive and less efficient), so use this machine park. And next is old news very shaggy's. But in a completely operational condition. Decided to keep it in production as active monument. A kind of "player-coach".

13. The color of items is done on automatic powder coating line, but with mandatory visual inspection and touch-up hand sprayer complex surfaces.

14. According to the representative of the plant, even in the most successful year of great importance was given to health and used in the tools and materials. Honestly, with the move to believe weakly, but what I saw in the shops, it confirms.

15. Now it's time to make a frame for undercar trucks. First prepared sheets of metal joints are specially adapted and prihvatyvayut welding.

16. Next comes in automatic robot welder. It is with these machines many years ago started a global modernization of welding equipment. Inaccessible places boil manually.

17. Almost finished bogie frame. As the quality of the trolley and wheel sets - is the safety of passengers, the requirements for the quality - the highest. Moreover, the item is put on the personal stamp of all who worked with her. And who checked and controlled. All these data are then stored at all times of operation of the trolley and wheel sets.

18. In the foreground is a pile of bogie frames for underground car 81-760 / 761 "Oka". TIZ makes them for Metrovagonmash.

19. Very smart machine finishing bogie frame. Special sensors are checked dimensions and axis. From these new coordinates axes are measured and drilled holes are processed edge. Ie for example, if the bracket has been welded offset couple of millimeters, the machine recognizes this and the hole will be drilled in the bracket, regardless of the desired location.

20. Now the production of wheel sets. Axis itself machined in place at railway wheels that come on TVZ with different plants, including with Vyksa Steel Works, bore mounting hole (wheel hub).

21. Nozzle wheel axle. There are hot and cold method of attachment. It is used cold. The inner diameter of the hole in the wheel slightly smaller than the outer diameter of the axle. And the press is mounted on the wheel axle with a predetermined force. Fixed by a special process monitoring device with graphic recording charts pressing.

22. Ready wheelsets are sent to the assembly trolleys.

23. Finished truck new design passenger car with disc brakes.

24. And this is the old, familiar to all construction truck. It is now produced on a nearby plant in Tver.

25. Press for hot forging. On it with the help of special stamps are obtained from parts of complex shape preforms in a preheated hot gas furnaces.

26. Now go through the foundry. On this photo you can see a nondescript literally technical revolution in the foundry business. If you need to cast a simple item without cavities inside, it's simple. But if the item is complex and inside the cavity and are channels? There are two options. In the first case, the inside of the flask is placed inside a wax model. It gives the internal structure and pouring the metal melts and flows. But it can do simple things. And if complicated? Then the internal cavities formed using sand models. Previously, tamp them by hand, and on the day of one person could make a dozen, since the work is very laborious, requires high precision and everything manually. Who makes the car model sand. The result of her work - in the photo. Once a minute and a half, two pops sand model. And then, after setting the items on the sand shaker model breaks down and poured out the details.

27. The lower part of the flask with the established model of sand.

28. Issuance of iron.

29. The bucket is small enough as it takes a certain temperature to ensure the quality of metal casting - a large number of metal do not have time to pour into the flask, the cooling time is limited

30. manages to pour a few flasks and again go for the grant of iron.

31. Complete details of the foundry and surface treatment.

32. Now go look at the body assembly. First on special stocks welded frame of the car. Install and undercar equipment pave communication.

33. In parallel with the assembly frame body on a special line of cars manufactured sidewall. Assembly and welding process is automated, conducted with minimal human intervention.

34. Roof Sheathing first welded in flat form, and then flipped her on a special stand is attached to a semicircular shape. Arc welded and the roof is taking shape and stiffness.

35. Finally, all parts of the body (frame, sidewalls, end walls and roof) are connected together in the finished product - the foundation of the future of the car.

36. First comes potholder all incoming units and parts.

37. Further, all exterior horizontal seams species boil automatic settings. But the rest - hands.

38. All the car is almost ready. At least its skeleton. As you can see, there is no longer even a heater (or rather, the boiler) installed.

39. Wagon after applying thermal insulation coatings and flooring.

40. Next is essentially an ordinary assembly of large number of components and their verification. The photograph is an installation of water supply system. The wizard is ready to install a system of water disinfection.

41. The assembly is made on the positions - each run only certain actions. Then the carriage moves to the next position. Here they come already painted.

42. The car after the installation of almost all internal systems. Now it's time to set the partition and mount that in total will see passenger.

43. The plant is a major supplier of passenger cars for the "daughter" Railways - Federal Passenger Company. But the range of products the company is very extensive.

44. The new cars with seats and now include a train of constant formation, including specialties.

45. Full production car takes about 70 days. For double-decker cars, the figure is about 100 days. This is the period of manufacture of the first part to the finished car. In car assembly shop directly on the assembly of the finished product on the average car spends 12 days.

46. The main (left) serial line occupy wagons for Railways. On average, this time standing staff and dining cars. A right line is occupied by other projects. At the time of the shooting were sleeping cars for international traffic (dimension RIC) - a joint project of TIZ and Siemens.

47. wagons for the railways of Kazakhstan.

48. Since 2008, for the needs of Russian Railways were delivered in 2800 razllichnyh cars. These new cars are a priority on the formation and renewal of firm and fast trains.

49. Normal compartment car, I will not show you, and so many photos. But the presence of the socket in the compartment is very pleasing.

50. This lift for disabled staff car.

51. Special coupe and a toilet for them is only in this car. See how to make a broadening of passage to stroller could pass.

52. Now all of a body made of stainless steel. On the showground plant last serial car from ordinary carbon steel. Occasionally, if desired, the customer, the plant fills orders on cars on the old technology. But for the customer is a double edged sword. The difference in price of the car with a body made of stainless steel and normal - less than a million rubles. And the life of the car, stainless steel is 40 years against 28. By the way, learned to plant a secret which torments me long ago. You see at the end of the car show "mileage - 450". This means that the surface of the coupler and the buffer is fused additional metallic layer of high strength which provides carriages running without replacement of the wear parts is not less than 450 thousand. Km.

53. Two-storey car developed on the initiative of Russian Railways. About him so much already written that will not elaborate. On a photo the first prototype, the prototype on which the Company holds a test and develop the design and technology of this innovative product. To the credit of the plant must be said that this prototype is made in just 8 months from the start of the design - from the first line in the drawing. Few competitors, even in the world market, capable in such a short time to put on the production of a completely new product.

54. The first subway car, released at the factory. First, "Oka" collected in Mytishchi, then part of the order was sent to Tver. It was made. Who do TVZ only metro bogie frames.

55. Sleeping car dimensions RIC for international communications - a joint project of TIZ and Siemens commissioned by the Railways. Note the very broad surface of the end bellows.

56. At the train dwell. Coupe - in general, everything is familiar.

57. But as the door opens the compartment. Surprisingly, she mirror inside, but in the clear, it blocks a passage. Not very well, in my opinion, constructive solution, although the design was designed by one of the giants of the global car building - by «Siemens».

58. Each car has a shower.

59. washbasin under the table. But underneath there is no openers. :)

60. The Panorama Factory. Motor transport shop and railway line of finished products. Overs were painting shops, climate station for testing, central laboratory and a lot else. But already many photos. And until 2030 Railways will purchase 16, 5 thousand. Wagons at 774, 5 billion. Rubles, of which in the next three years - 2000.