1469

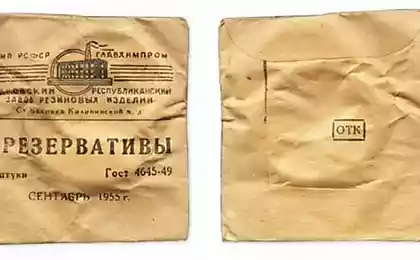

How are condoms (13 pics + text)

To ensure that the Ukrainians of condoms is the only factory in the country for their production "Perfect" is working round the clock. The production process begins with condoms mixing. Latex - rubber tree sap - imported from Malaysia. In the factory, it is added only components that accelerate the curing process, wherein the latex becomes resilient. In some countries, produce condoms and synthetic materials such as polyurethane. At the touch they are similar to polyethylene and have a very low elasticity and lower than latex, strength. To be held in the very premises, I was given a shoe and gown and asked the presence of allergy to ammonia. Why, I realized later. When we entered the shop, the first time it was hard to breathe: the pungent smell of ammonia and latex greatly hurt his eyes. "The production is fully automated, so stay here permanently nobody cares, - says Vladimir Dobush, head of the factory shift. - The operator was watching him through a special window of his office behind the wall ».

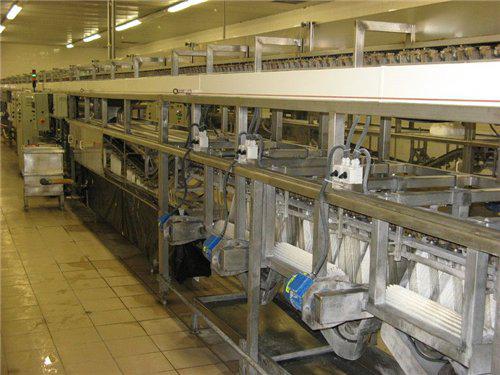

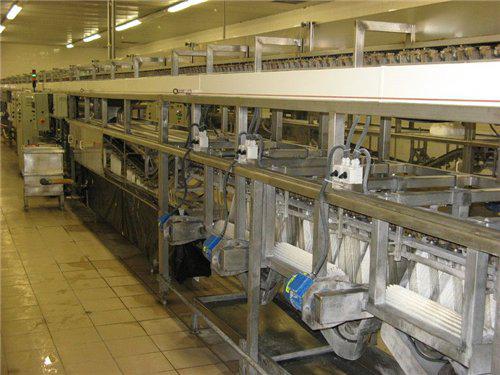

The shop two production lines. In the long-Kie ties bath filled with a mixture of glass flasks fall phallic. For the manufacture of each type of bulb used with different surfaces - to get ribbed condom with pimples or classical, smooth.

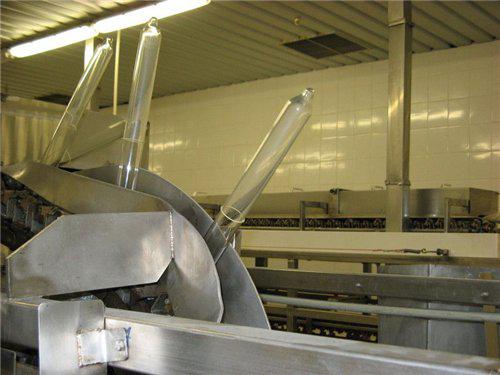

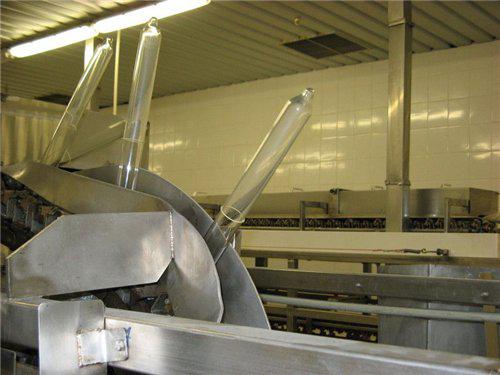

Flasks, moving on, "emerges" from the bath. Then prezervativny semifinished product is dried, and a portion of the latex flows from the flasks. In the manufacture of ultra-thin condom chain is moving slowly to keep pace with longer drain the mixture. While latex flasks more transparent, it is virtually invisible.

Next - repeated soaking. It is necessary to specify the desired product thickness. Then the flask to move forward. In the next stage with rotating brushes along them on condoms curled rim, and "semi-finished" enter the curing chamber. From there, go have translucent milky products. Then the chain is moving in the bath, soaking the latex condom and can be easily removed from the flask. To speed up the stripping of the form in the soap solution and ammonia are added. The products are then stray from flasks using jets of water and rotating brushes in the reservoir.

18, 5 cm - European standard

The next stage - the final. The device is very similar to household washing machines, only much larger, condoms are "washed" in water at room temperature. There are added powder to the product are not stuck, and the disinfectant solution. Further condoms are sent to the same drying apparatus in front. The process of washing and drying takes a little over one and a half hours.

Then begins the most delicate and important part of the production: Condoms come to the lab to undergo several stages of quality control. In the first stage of the party in the 4-6 thousand articles selected 100 pieces. "That's enough to judge the quality of the entire batch, - says Vladimir. - If at this stage there is a discrepancy norm, then the party is rejected. " Condoms are weighed and their length is measured. Each piece must weigh about a gram, and be up 18, 5-19 centimeters. This is the European standard, which, as explained in the lab, and perfectly realized in the Ukrainian market. So while a factory does not plan to produce non-standard sizes of condoms.

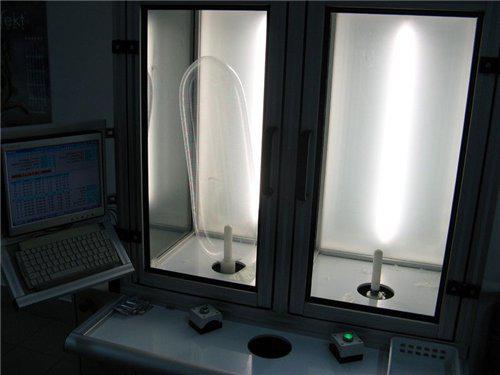

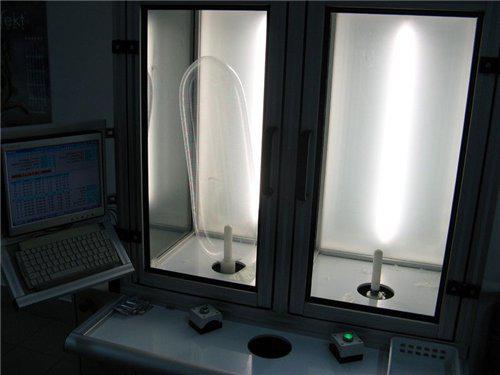

In the laboratory, and then I shuddered from the sharp sounds. It burst condom - so check them for strength. 100 already weighed and measured articles 5 is selected to check the pressure and volume enclosing air. The special chamber is inflated condom. At the moment when it bursts, the instrument captures how much air the product together and how much survived. The bursting of the condom when I endured a pressure of 2, 5 kilopascals and hold about 40 liters of air. A norm GOST even for ultra - 1, 1-1, 2 kilopascals, air volume - about 18 liters.

"Generally speaking, one party of condoms at all stages of the control is allowed up to 15% of marriage - says Vladimir Dobush. - If the party is "bad" and the percentage of marriage more we throw away all the 4-6 thousand, as further testing and packing becomes uneconomical. " Incidentally, in each flask were squeezed at the base number which is printed on beneath the rim of the condom. Number of defective condom recorded. If marriage is repeated in the same flask, it is replaced.

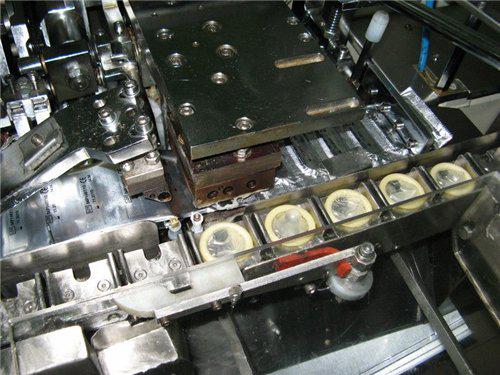

Checked electronics

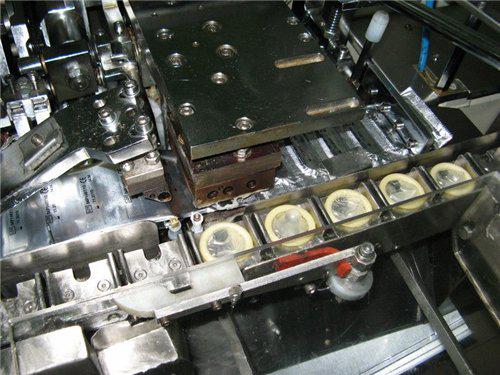

After all these manipulations of the whole batch of condoms 4-6 thousand pieces sent to the first stage of the electronic testing. During testing machine sitting operators that manually put the product on the metal electrodes in the form of a condom attached to the instrument. Through them, the current is passed, and the computer records, he passes through the article. Condoms, who missed the current, become marriage. The rest go to the next step. To do this, selected 30 pieces. They are put manually on the electrode, and then filled with electrolyte solution and descend into the container, and the filled electrolyte. If the equipment is fixed, that the products passed the current, so they have micropores. And the whole lot is considered unfit and sent to the trash, and the testing machine, which did not find the marriage - for inspection and repair. But such cases are rare. Most whole Party after checking electronics disinfected and sent to the packing line.

How to prolong the feeling

Before you seal the condom, each of them using the dosage machines add drops of silicone oil-lubrication.

In the production of condoms, "prolonging the pleasure," but grease is added lidocaine which acts "zatormazhivayusche" on the nerve endings, or flavor - the production of perfumed products. The oil is added only aromatizatorypischevye supplements. Quality of packaging is also checked in a special vacuum chamber.

The factory itself is working around the clock in three shifts of 8 hours, and produces about 17 million condoms a year. Before changing the factory workers take a shower and be sure to pass in a "clean zone" wear overalls. In the factory every three hours to wash floors and maintains a high level of humidity to avoid dust.

A source

The shop two production lines. In the long-Kie ties bath filled with a mixture of glass flasks fall phallic. For the manufacture of each type of bulb used with different surfaces - to get ribbed condom with pimples or classical, smooth.

Flasks, moving on, "emerges" from the bath. Then prezervativny semifinished product is dried, and a portion of the latex flows from the flasks. In the manufacture of ultra-thin condom chain is moving slowly to keep pace with longer drain the mixture. While latex flasks more transparent, it is virtually invisible.

Next - repeated soaking. It is necessary to specify the desired product thickness. Then the flask to move forward. In the next stage with rotating brushes along them on condoms curled rim, and "semi-finished" enter the curing chamber. From there, go have translucent milky products. Then the chain is moving in the bath, soaking the latex condom and can be easily removed from the flask. To speed up the stripping of the form in the soap solution and ammonia are added. The products are then stray from flasks using jets of water and rotating brushes in the reservoir.

18, 5 cm - European standard

The next stage - the final. The device is very similar to household washing machines, only much larger, condoms are "washed" in water at room temperature. There are added powder to the product are not stuck, and the disinfectant solution. Further condoms are sent to the same drying apparatus in front. The process of washing and drying takes a little over one and a half hours.

Then begins the most delicate and important part of the production: Condoms come to the lab to undergo several stages of quality control. In the first stage of the party in the 4-6 thousand articles selected 100 pieces. "That's enough to judge the quality of the entire batch, - says Vladimir. - If at this stage there is a discrepancy norm, then the party is rejected. " Condoms are weighed and their length is measured. Each piece must weigh about a gram, and be up 18, 5-19 centimeters. This is the European standard, which, as explained in the lab, and perfectly realized in the Ukrainian market. So while a factory does not plan to produce non-standard sizes of condoms.

In the laboratory, and then I shuddered from the sharp sounds. It burst condom - so check them for strength. 100 already weighed and measured articles 5 is selected to check the pressure and volume enclosing air. The special chamber is inflated condom. At the moment when it bursts, the instrument captures how much air the product together and how much survived. The bursting of the condom when I endured a pressure of 2, 5 kilopascals and hold about 40 liters of air. A norm GOST even for ultra - 1, 1-1, 2 kilopascals, air volume - about 18 liters.

"Generally speaking, one party of condoms at all stages of the control is allowed up to 15% of marriage - says Vladimir Dobush. - If the party is "bad" and the percentage of marriage more we throw away all the 4-6 thousand, as further testing and packing becomes uneconomical. " Incidentally, in each flask were squeezed at the base number which is printed on beneath the rim of the condom. Number of defective condom recorded. If marriage is repeated in the same flask, it is replaced.

Checked electronics

After all these manipulations of the whole batch of condoms 4-6 thousand pieces sent to the first stage of the electronic testing. During testing machine sitting operators that manually put the product on the metal electrodes in the form of a condom attached to the instrument. Through them, the current is passed, and the computer records, he passes through the article. Condoms, who missed the current, become marriage. The rest go to the next step. To do this, selected 30 pieces. They are put manually on the electrode, and then filled with electrolyte solution and descend into the container, and the filled electrolyte. If the equipment is fixed, that the products passed the current, so they have micropores. And the whole lot is considered unfit and sent to the trash, and the testing machine, which did not find the marriage - for inspection and repair. But such cases are rare. Most whole Party after checking electronics disinfected and sent to the packing line.

How to prolong the feeling

Before you seal the condom, each of them using the dosage machines add drops of silicone oil-lubrication.

In the production of condoms, "prolonging the pleasure," but grease is added lidocaine which acts "zatormazhivayusche" on the nerve endings, or flavor - the production of perfumed products. The oil is added only aromatizatorypischevye supplements. Quality of packaging is also checked in a special vacuum chamber.

The factory itself is working around the clock in three shifts of 8 hours, and produces about 17 million condoms a year. Before changing the factory workers take a shower and be sure to pass in a "clean zone" wear overalls. In the factory every three hours to wash floors and maintains a high level of humidity to avoid dust.

A source