2998

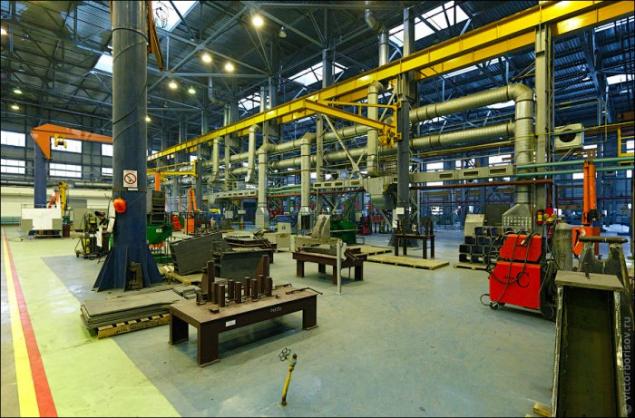

Plant for the production of locomotives

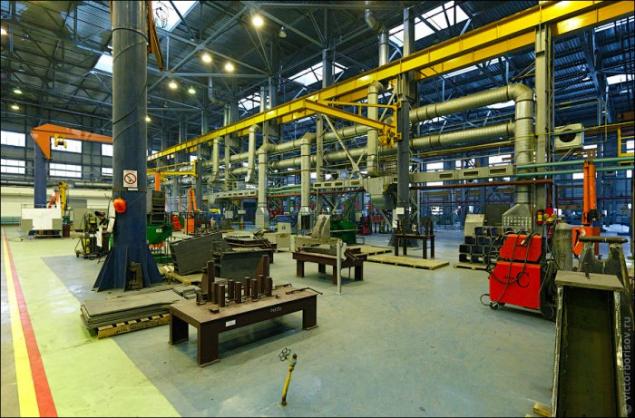

General Electric Transportation (GETS) is one of the world's leading manufacturers of railway equipment. In 2009, GE, together with the national railway company "Kazakhstan Temir Zholy" (KTZ) opened the locomotive assembly plant in Astana with 100 locomotives a year. Collected at the plant main cargo diesel locomotives TE33A series «Evolution» (model ES44ACI).

The new locomotive is a six-axle single-section locomotive power 3356 kW (4562 hp) 12-cylinder four-stroke diesel V-shaped type GEVO12. It is equipped with a microprocessor control system with electronic fuel injection and on-board diagnostic system. The maximum construction speed - 120 km / h. Compared with the previous generation diesel engines reduce these harmful emissions by more than 40%, the cost of fuel and lubricants - 17%. This allows for the entire life of the locomotive save about 1, 1 million. Liters of diesel fuel.

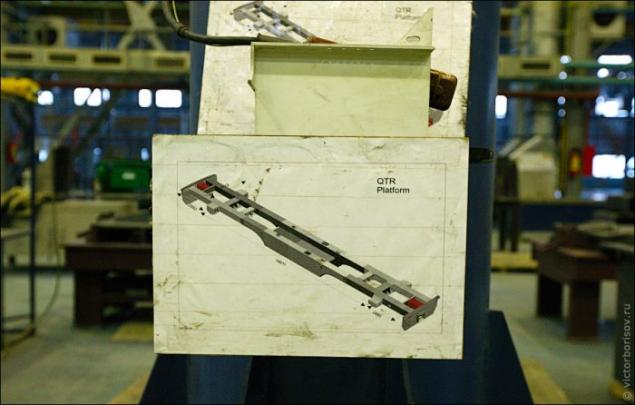

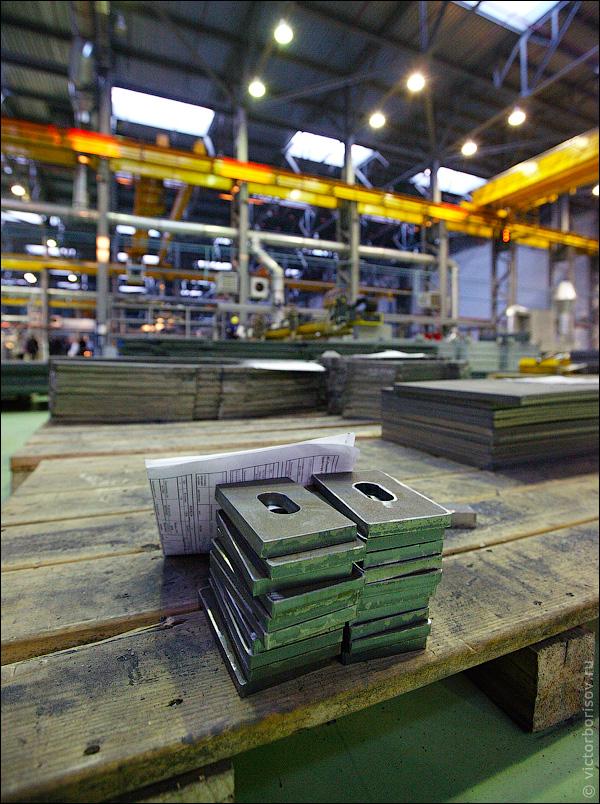

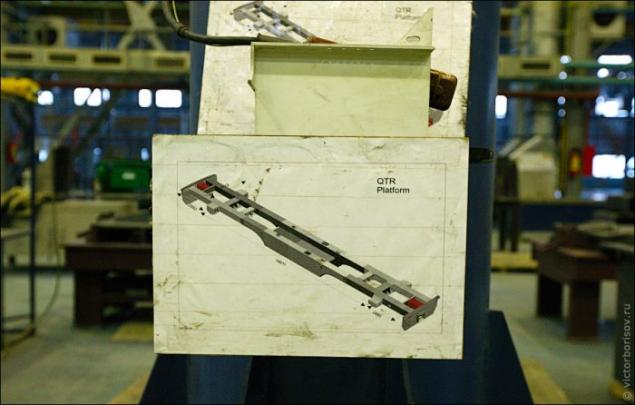

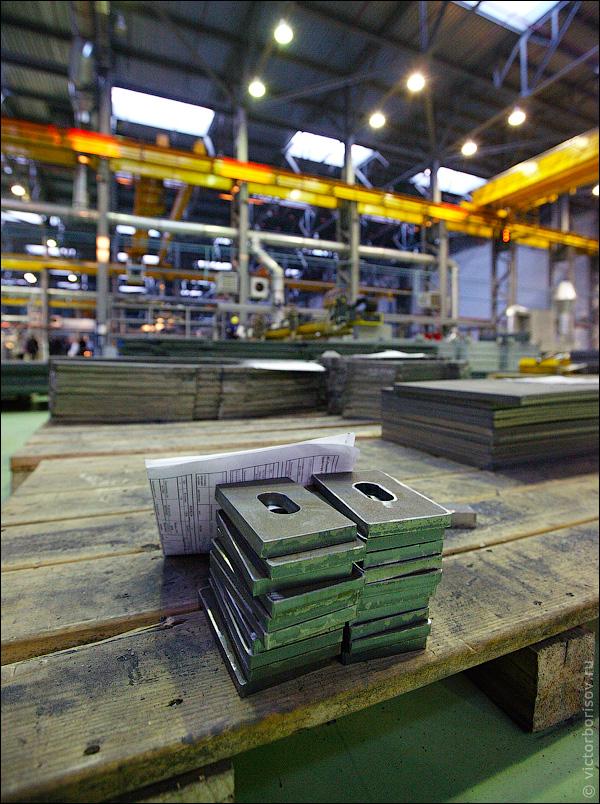

A key element of the cycle is the manufacture of locomotive assembly frame of the locomotive, the development of which allowed us to obtain a share of the Kazakhstan component in picking locomotives to 18%. In the future, the plant will be started to produce diesel and diesel generator compartments, which will bring the level of localization of production to 34%.

Medium-term outcome of further work to equip enterprises and the introduction of new products will be the development of production at our facilities cabs, locomotive bogie frame and spare parts. Currently, these units are supplied to the plant already assembled.

Until 2014, the locomotive assembly plant in Astana is planning to release more than 400 new-generation locomotives series Evolution, about a third of them will be sent for export.

The new locomotive is a six-axle single-section locomotive power 3356 kW (4562 hp) 12-cylinder four-stroke diesel V-shaped type GEVO12. It is equipped with a microprocessor control system with electronic fuel injection and on-board diagnostic system. The maximum construction speed - 120 km / h. Compared with the previous generation diesel engines reduce these harmful emissions by more than 40%, the cost of fuel and lubricants - 17%. This allows for the entire life of the locomotive save about 1, 1 million. Liters of diesel fuel.

A key element of the cycle is the manufacture of locomotive assembly frame of the locomotive, the development of which allowed us to obtain a share of the Kazakhstan component in picking locomotives to 18%. In the future, the plant will be started to produce diesel and diesel generator compartments, which will bring the level of localization of production to 34%.

Medium-term outcome of further work to equip enterprises and the introduction of new products will be the development of production at our facilities cabs, locomotive bogie frame and spare parts. Currently, these units are supplied to the plant already assembled.

Until 2014, the locomotive assembly plant in Astana is planning to release more than 400 new-generation locomotives series Evolution, about a third of them will be sent for export.