366

The best solution for the flooring and waterproofing

Five million one hundred nineteen thousand three hundred seventy four

How to perform a quick coupler with a small cost? The optimal solution for industrial concrete floors. The execution of the screed and flooring coating surface shall meet the following minimum requirements:

For large commercial or industrial area is difficult to perform the flooring is tile or laminate. Materials are not resistant to mechanical damage (e.g., transportation or transport trucks). In addition, the cost of the job in 1 square meter would be unreasonably expensive and unprofitable.

The optimal solution for industrial concrete floors. What are the qualitative benefits received by the buyer?

The fixation to the concrete surface is fast

Polymeric industrial floor has high parameters of adhesion – establishes a quick connection with a concrete screed. No need to use special equipment for pressing cover and a large staff of technical personnel.

The resistance to dynamic shock and damage

The main requirement for installation of the cover on the manufacture and physical properties of the composition. Floors must withstand drop loads and exposure to aggressive chemical elements. Industrial floors can withstand a high load in compression and bending. An additional advantage – resistance to abrasion of the coating (for high traffic – the movement of small loading vehicles and containers).

Security

The coating has a high property to resist burning open flame. In case of fire does not emit toxic substances and does not support the development of fire.

What needs protecting industrial facility in the enterprise?

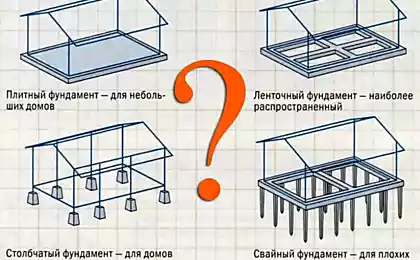

In the production room should be provided with a high level of waterproofing. The penetration of moisture destroys the integrity of a monolithic structure. Leads to damage of internal engineering communications.

To ensure high performance of the industrial building or hangar must be made waterproofing. The process minimizes the risks associated with the decay of floors and finishes. The difficulty lies in the fact that the negative impact of increased exposure to moisture is visually difficult to determine. The danger may be set when the object is already received significant damage and wear. Waterproofing maintains and supports the protection of internal partitions of the object and does not allow the primary destruction of foundations and subsidence of the building.

How to perform a quick coupler with a small cost? The optimal solution for industrial concrete floors. The execution of the screed and flooring coating surface shall meet the following minimum requirements:

- Low cost costs when carrying out works;

- Great waterproofing;

- Use of the material over a large area of the object;

- There are no additional requirements on the geometry of the room, bumps and other obstacles for flooring;

- The term of the flooring should be of high attenuation and high maintainability. If possible, small repairs should be no more in 5-8 years (with intensive use).

For large commercial or industrial area is difficult to perform the flooring is tile or laminate. Materials are not resistant to mechanical damage (e.g., transportation or transport trucks). In addition, the cost of the job in 1 square meter would be unreasonably expensive and unprofitable.

The optimal solution for industrial concrete floors. What are the qualitative benefits received by the buyer?

The fixation to the concrete surface is fast

Polymeric industrial floor has high parameters of adhesion – establishes a quick connection with a concrete screed. No need to use special equipment for pressing cover and a large staff of technical personnel.

The resistance to dynamic shock and damage

The main requirement for installation of the cover on the manufacture and physical properties of the composition. Floors must withstand drop loads and exposure to aggressive chemical elements. Industrial floors can withstand a high load in compression and bending. An additional advantage – resistance to abrasion of the coating (for high traffic – the movement of small loading vehicles and containers).

Security

The coating has a high property to resist burning open flame. In case of fire does not emit toxic substances and does not support the development of fire.

What needs protecting industrial facility in the enterprise?

In the production room should be provided with a high level of waterproofing. The penetration of moisture destroys the integrity of a monolithic structure. Leads to damage of internal engineering communications.

To ensure high performance of the industrial building or hangar must be made waterproofing. The process minimizes the risks associated with the decay of floors and finishes. The difficulty lies in the fact that the negative impact of increased exposure to moisture is visually difficult to determine. The danger may be set when the object is already received significant damage and wear. Waterproofing maintains and supports the protection of internal partitions of the object and does not allow the primary destruction of foundations and subsidence of the building.