550

How to insulate a pitched roof PIR insulation

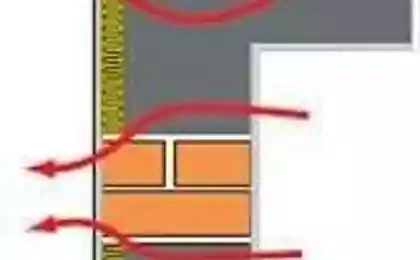

In connection with constant growth of energy prices among private developers is growing interest in building energy efficient homes. One of the key features of such building is the construction of a closed insulating circuit, minimizing the number of thermal inhomogeneities as well as clipping all the "cold bridges", resulting in increased heat loss.

In the pursuit of energy efficiency, many developers overlooked that in addition to the walls and Foundation, you should insulate the roof, because the total roof area exceeds the total area of the walls of the house.

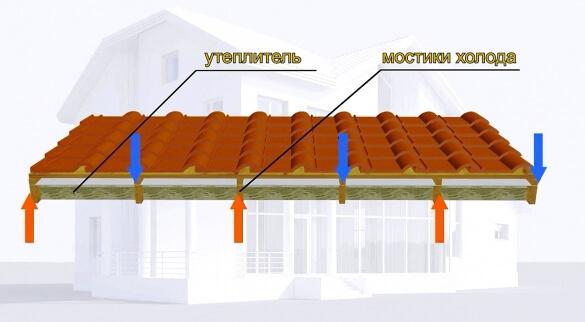

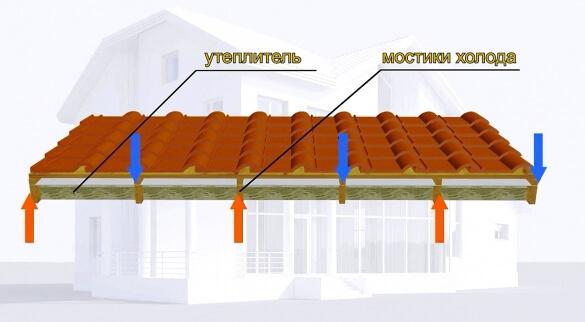

Typically, for thermal insulation of pitched roofs the insulation is installed vraspor between the rafters. But with this method of mounting the rafters are "cold bridges".

To insulate the rafters and thereby to increase the energy efficiency of your home, you can resort to the new way of insulating the roof. Heat loss through the roof range from 20 to 30% of total heat loss of the building.

You should also remember that the polyisocyanurate (PIR-based) is a thermosetting polymer with high resistance. In the event of a fire when exposed to fire the material is the carbonization and coking of the external surface of the insulation, i.e. the formation of so-called "carbonaria" for the inner layers of the polymer. Accordingly, the flame is not covered, which is especially important when choosing the material for insulation of the roof.

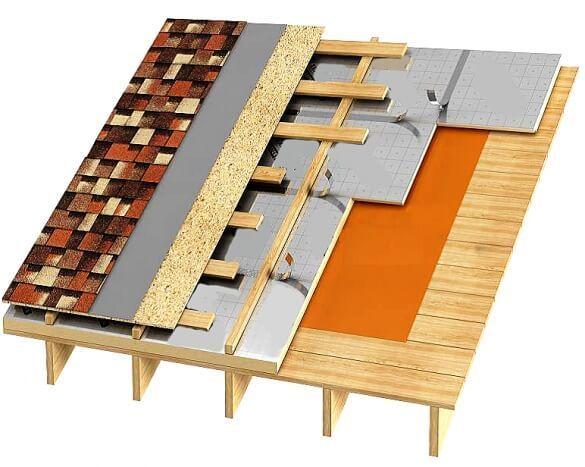

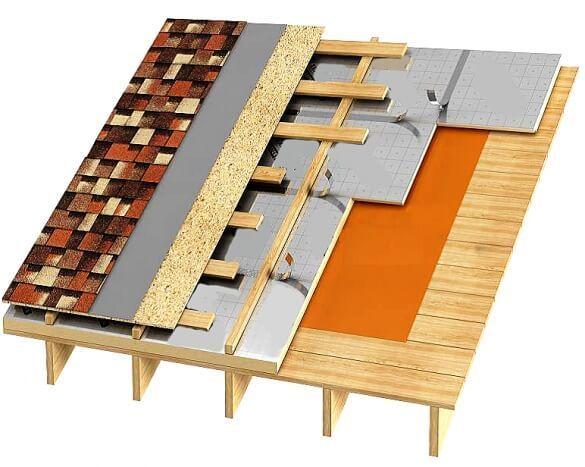

Having dealt with special insulation for pitched roof insulation PIR, go to practice and consider the "pie" of the roof.

The nuances of installation PIR insulation for pitched roof

As building practice shows, the choice of method of teploizolirovannye of the roof must be determined at the stage of designing the house. In this case, a balanced system, where each element is in place.

In the case of pitched roof insulation PIR boards you can choose three method of installation of the insulation. This — post mounting plates and Mitropoly nastroeniy. The most interesting is the third variant of the thermal insulation of pitched roofs.

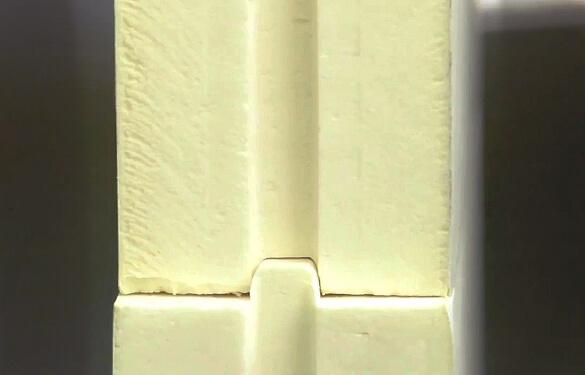

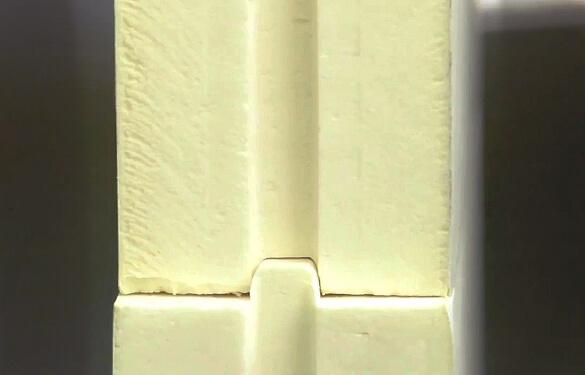

The technique involves the simultaneous stacking of the following layers of roof insulation, wind - and hydroprotection and kontrobreshetki sequentially, from bottom to top along the slope of the roof on each set of plates.Plates are placed vrazbezhku, are joined to each other via connecting the tongue-and-groove. The inside of the roof is mounted vapour barrier membrane. For effective and rapid operation it is recommended to use a plate size 1200х2400 mm. Plates are placed directly on the rafters and tightly adjusted to each other through tongue and groove connection.

Immediately after installation of each row of plates on them is laid a layer of roll wind - and hydroprotection. An alternative solution to waterproofing the joints of plates can be foil tape. Following the operation, details of which we describe below, is the mount kontrobreshetki (bar with 60x40 mm 50x50 mm).

Stacked plate, for sealing the joints should be cemented with self-adhesive aluminium tape.

Truss system operates in dry conditions, at constant temperature and equilibrium moisture content. In gluing of the joints of plates with foil tape we have a continuous and sealed layer which prevents the entire structure from moisture due to possible condensation and moisture from the outside.Stacked plate formed kontrobreshetku. For this purpose along the rafter feet are nailed or screwed to the bar thickness 30-50 mm. Thus is formed ventanal required for ventilation of roof space and insulation PIR is rigidly fixed between the rafters and the brick kontrobreshetki.

Bar kontrobreshetki (across the rafters) puts the corresponding crates, which in the future will be the installation of finish roofing. It can be metal or shingles.

When erecting roof trusses important point is the reliable fastening of the rafters to create a solid future roof frame. Also I advise to pay attention to the processing of wood, fire and bioprotective compositions.

During sinking through the PIR insulation chimneys comply with fire requirements. To this end, the PIR slabs and chimney leaving a gap, which is filled with mineral wool material.Moving on. When mounting thermal insulation at the ridge insulation is trimmed so that the space plates were placed back to back, and top to leave a wedge-shaped gap, about 15-30 mm, which zapisyvaetsya and glued with aluminum tape.

Another variant of the installation of the PIR boards is them laying on a solid wood base laid on top of the rafters. The wooden beams remain exposed and as well as and base become the decorative element of the interior roof spaces, attics.

"Pie" of the roof consists of the following layers (bottom to top):

When installing a roof system on the type of open bottom wooden rafters vapor-tight layer should be placed on solid decking boards, which is the finishing layer in the interior of the room. In areas of overlap vapor barrier film, it is necessary to glue double sided sticky tape.

PIR insulation boards have a lot of flexibility. This is reflected in the ability to mount insulation inside roof barriers under the rafters. This method is most suitable for renovation of old roofs. "Pie" of the roof in this case looks like.

Besides, there is an option allowing for the installation of the PIR boards between rafters so that between them and the wooden beams were left a small gap (about 10-15 mm), which is then zapisyvaetsya. This option is a classic way of insulating pitched roofs.

Due to the gap of 10-15 mm, reduced requirements to the quality of slicing plates working. That plate didn't fall out, they are fixed between the rafters in the usual wedges from the same isolation. Then all Assembly joints filled with foam.

How to avoid mistakes when installing PIR thermal insulation

We have considered the basic nuances that need to be considered when insulating a pitched roof PIR slabs. In conclusion, we present the recommendations of the manufacturers, which will allow to avoid mistakes in the installation of this insulation.

Source: www.forumhouse.ru/articles/house/7083

In the pursuit of energy efficiency, many developers overlooked that in addition to the walls and Foundation, you should insulate the roof, because the total roof area exceeds the total area of the walls of the house.

Typically, for thermal insulation of pitched roofs the insulation is installed vraspor between the rafters. But with this method of mounting the rafters are "cold bridges".

To insulate the rafters and thereby to increase the energy efficiency of your home, you can resort to the new way of insulating the roof. Heat loss through the roof range from 20 to 30% of total heat loss of the building.

You should also remember that the polyisocyanurate (PIR-based) is a thermosetting polymer with high resistance. In the event of a fire when exposed to fire the material is the carbonization and coking of the external surface of the insulation, i.e. the formation of so-called "carbonaria" for the inner layers of the polymer. Accordingly, the flame is not covered, which is especially important when choosing the material for insulation of the roof.

Having dealt with special insulation for pitched roof insulation PIR, go to practice and consider the "pie" of the roof.

The nuances of installation PIR insulation for pitched roof

As building practice shows, the choice of method of teploizolirovannye of the roof must be determined at the stage of designing the house. In this case, a balanced system, where each element is in place.

In the case of pitched roof insulation PIR boards you can choose three method of installation of the insulation. This — post mounting plates and Mitropoly nastroeniy. The most interesting is the third variant of the thermal insulation of pitched roofs.

The technique involves the simultaneous stacking of the following layers of roof insulation, wind - and hydroprotection and kontrobreshetki sequentially, from bottom to top along the slope of the roof on each set of plates.Plates are placed vrazbezhku, are joined to each other via connecting the tongue-and-groove. The inside of the roof is mounted vapour barrier membrane. For effective and rapid operation it is recommended to use a plate size 1200х2400 mm. Plates are placed directly on the rafters and tightly adjusted to each other through tongue and groove connection.

Immediately after installation of each row of plates on them is laid a layer of roll wind - and hydroprotection. An alternative solution to waterproofing the joints of plates can be foil tape. Following the operation, details of which we describe below, is the mount kontrobreshetki (bar with 60x40 mm 50x50 mm).

Stacked plate, for sealing the joints should be cemented with self-adhesive aluminium tape.

Truss system operates in dry conditions, at constant temperature and equilibrium moisture content. In gluing of the joints of plates with foil tape we have a continuous and sealed layer which prevents the entire structure from moisture due to possible condensation and moisture from the outside.Stacked plate formed kontrobreshetku. For this purpose along the rafter feet are nailed or screwed to the bar thickness 30-50 mm. Thus is formed ventanal required for ventilation of roof space and insulation PIR is rigidly fixed between the rafters and the brick kontrobreshetki.

Bar kontrobreshetki (across the rafters) puts the corresponding crates, which in the future will be the installation of finish roofing. It can be metal or shingles.

When erecting roof trusses important point is the reliable fastening of the rafters to create a solid future roof frame. Also I advise to pay attention to the processing of wood, fire and bioprotective compositions.

During sinking through the PIR insulation chimneys comply with fire requirements. To this end, the PIR slabs and chimney leaving a gap, which is filled with mineral wool material.Moving on. When mounting thermal insulation at the ridge insulation is trimmed so that the space plates were placed back to back, and top to leave a wedge-shaped gap, about 15-30 mm, which zapisyvaetsya and glued with aluminum tape.

Another variant of the installation of the PIR boards is them laying on a solid wood base laid on top of the rafters. The wooden beams remain exposed and as well as and base become the decorative element of the interior roof spaces, attics.

"Pie" of the roof consists of the following layers (bottom to top):

- open the bottom of the truss system;

- solid wooden base with protogenoi lower surface;

- vapor barrier;

- plate PIR;

- counter lathing;

- the finish roofing.

When installing a roof system on the type of open bottom wooden rafters vapor-tight layer should be placed on solid decking boards, which is the finishing layer in the interior of the room. In areas of overlap vapor barrier film, it is necessary to glue double sided sticky tape.

PIR insulation boards have a lot of flexibility. This is reflected in the ability to mount insulation inside roof barriers under the rafters. This method is most suitable for renovation of old roofs. "Pie" of the roof in this case looks like.

Besides, there is an option allowing for the installation of the PIR boards between rafters so that between them and the wooden beams were left a small gap (about 10-15 mm), which is then zapisyvaetsya. This option is a classic way of insulating pitched roofs.

Due to the gap of 10-15 mm, reduced requirements to the quality of slicing plates working. That plate didn't fall out, they are fixed between the rafters in the usual wedges from the same isolation. Then all Assembly joints filled with foam.

How to avoid mistakes when installing PIR thermal insulation

We have considered the basic nuances that need to be considered when insulating a pitched roof PIR slabs. In conclusion, we present the recommendations of the manufacturers, which will allow to avoid mistakes in the installation of this insulation.

- The presence of gas-tight linings on the surface of the plates and the property of the PIR does not absorb moisture are not grounds for rejection of the device vapor barrier. Vapor barrier is necessary to protect the joints of plates, which even with tight fitting can not be considered absolutely progrmatically.

- You should pay attention to the feasibility of design solutions "PIR-plate on top of the rafters" for roofs with a small angle rays and rare step of rafters for roofs with complex geometries, where the formation of the so-called snow bags. For such roofs, it is recommended to use the solution micropiling insulation in combination with the device a continuous layer of insulation on the bottom rafters.

- Nastroennoy method of isolation involves the production of works outside, so when installing the insulation on their own should follow safety rules when working at height.

Source: www.forumhouse.ru/articles/house/7083