527

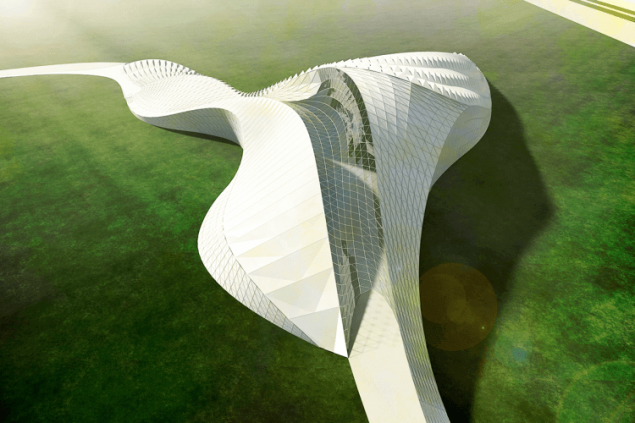

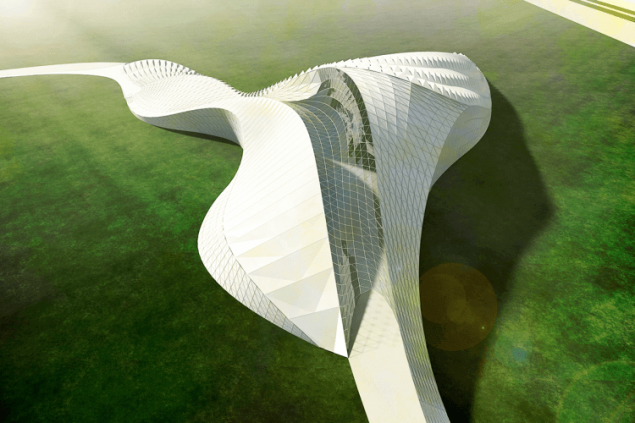

Cazza — environmentally friendly 3D printing houses

Cazza, the company plans to automate the entire process of building houses. While such construction will be environmentally friendly, and the buildings to be printed on special technology and proprietary materials developed by the company. The company may build a house of 100 square meters per 24 hours.

Chris Kelsey — millionaire and serial entrepreneur — founder and CEO at building automation Cazza. When Kelsey first learned about climate change and other environmental issues, he became really scary. Now his goal — to create sustainable and affordable housing.

In Cazza he wants to automate a large part of the construction process as possible, from laying the Foundation before building the walls. The company has developed its own proprietary building material: for consistency it is similar to concrete and 80% is from recycled substances.

Cazza other product like portable 3D printer. He can squeeze this stuff on the walls layer by layer. Cazza can build a house 100 square meters in 24 hours. Besides using the software users can create 3D models.

3D printing buildings do companies like Chinese WinSun, which promises to print in Saudi Arabia, the house for $1.5 million, or WATG Urban Architecture, which is going to create the first home of the free form in the United States.

But, unlike the houses of other companies, built Cazza require no further Assembly. Technology Cazza allow you to print right on the spot. But automating the process will reduce construction costs and reduce the amount of waste that pollute the environment during normal construction homes. Currently, the company cooperates with construction companies in Asia and the middle East: in Dubai, Singapore and China. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: hightech.fm/2016/11/25/Cazza

Chris Kelsey — millionaire and serial entrepreneur — founder and CEO at building automation Cazza. When Kelsey first learned about climate change and other environmental issues, he became really scary. Now his goal — to create sustainable and affordable housing.

In Cazza he wants to automate a large part of the construction process as possible, from laying the Foundation before building the walls. The company has developed its own proprietary building material: for consistency it is similar to concrete and 80% is from recycled substances.

Cazza other product like portable 3D printer. He can squeeze this stuff on the walls layer by layer. Cazza can build a house 100 square meters in 24 hours. Besides using the software users can create 3D models.

3D printing buildings do companies like Chinese WinSun, which promises to print in Saudi Arabia, the house for $1.5 million, or WATG Urban Architecture, which is going to create the first home of the free form in the United States.

But, unlike the houses of other companies, built Cazza require no further Assembly. Technology Cazza allow you to print right on the spot. But automating the process will reduce construction costs and reduce the amount of waste that pollute the environment during normal construction homes. Currently, the company cooperates with construction companies in Asia and the middle East: in Dubai, Singapore and China. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: hightech.fm/2016/11/25/Cazza

Hippocratic face: What can you tell us about the health of features and complexion of the person

How to grow cherries and plums from green cuttings