580

Printed concrete with their hands

In an alternative decorative paving tiles, you can acquire or manufacture printed concrete with their hands. Technology for the production of printed concrete can create a decorative surface for garden paths that mimic stone, wood flooring, pavers, or even animal skins.

Thus, printed concrete provides a unique opportunity to combine the drawing a floor covering with overall architectural design of the building.

The history of technologyof Various concretes, designed for the decoration appeared in the US in the middle of the last century. Initially, this development was designed for the decoration and arrangement of the runways of military airfields. But printed concrete proved to be very reliable and durable coating.

He quickly gained popularity among the urban companies, and after – and private customers. The technology of manufacturing concrete printing has transformed the appearance of large cities and small villages, reconciling the architectural styles of past centuries with modern office centers and shopping pavilions.

The benefits of usingthe Advantages of stamped concrete presents the following qualities:

Training places and formworkto produce concrete printing, choose a warm dry day. The temperature should not be below +5°C minimum humidity will promote rapid drying of the workpieces. With the help of pegs and ropes enclose the area selected for coverage.

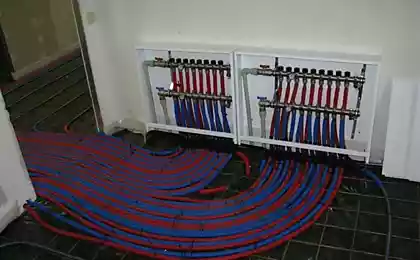

In the selected areas, remove the top layer of soil. If the coating is intended only for pedestrians – remove a layer of about 158 cm. For the site, which provides vehicular traffic, the soil removed to a depth of 20 cm obtained In the formwork poured a mixture of crushed stone and sand. Received the pillow thoroughly tamped. On top of the compacted cushion of stacked polyethylene film with an overlap of about 10 cm, put on top of the reinforcing mesh.

KneadingFor the production of concrete printing is best suited Portland cement M400 or M500 with the addition of various plasticizers. For decorative coatings in concrete it is recommended to add polypropylene fibre.

One cubic meter of concrete is 0.6 kg this Supplement. Polypropylene fiber significantly improves durability of the finished concrete and prevents the formation of cracks and chips on its surface. For the manufacture of decorative concrete with your hands requires the following components:

Around the perimeter of the formwork surface smooth corner trowel.Applying a decorative layerBefore applying the upper decorative layer working surface is treated with a fixative. About 70% of the required quantity of binder is applied manually on the matte surface of the concrete and smoothing aluminum trowel. Then scatter the remainder of the binder and smooth down the surface with steel trowel.

The following step – application of the hardener. This component represents a mixture of resistant pigments, filler and binder component. Each layer of the curing agent is rubbed into the surface until the outer layer of the printed concrete will not be smooth and evenly colored.

The creation of the terrain surface or simulationIf your goal was to make the surface of the stamped concrete relief imitating stone, brick or Board after application of the hardener wet surface should be treated with special presses, which give the concrete the required shape.

This operation must be performed with the still uncured concrete, while the surface is easy to push of your finger.Layingthe Prepared matrix is placed on the surface of the concrete. The first number is usually placed along the outside edge of the formwork. To achieve the perfectly smooth lines of the matrix should be closely pressed against each other. For final curing of decorative concrete you will need about two days. After that the concrete surface is cleaned, remove excess material with a stiff brush with a long NAP. The surface is washed and dried.

Applying an acrylic layerFor finishing of decorative concrete at its surface is applied a protective acrylic layer. This safeguard will reduce the harmful effects of the environment and will significantly increase the lifetime of printed concrete.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Manufacture of concrete with your hands requires special attention, careful selection of components and the exact observance of technology. But this coating perfectly decorate the interior of your home or garden and will add to the architectural ensemble of your home its own unique flavor. published

Source: tehno-beton.ru/beton/vidy/pechatnyj-texnologiya.html

Thus, printed concrete provides a unique opportunity to combine the drawing a floor covering with overall architectural design of the building.

The history of technologyof Various concretes, designed for the decoration appeared in the US in the middle of the last century. Initially, this development was designed for the decoration and arrangement of the runways of military airfields. But printed concrete proved to be very reliable and durable coating.

He quickly gained popularity among the urban companies, and after – and private customers. The technology of manufacturing concrete printing has transformed the appearance of large cities and small villages, reconciling the architectural styles of past centuries with modern office centers and shopping pavilions.

The benefits of usingthe Advantages of stamped concrete presents the following qualities:

- the gradual spread of decorative concrete;

- absolute environmental friendliness of the process. Technology of production of printed concrete does not provide for the use of harmful and toxic substances, and even in the course of long operation the coating of decorative concrete is absolutely safe for humans and the environment;

- the surface made of the stamped concrete that is resistant to corrosion and easy to clean materials at hand;

- decorative concrete coating is able to maintain its quality in the temperature range from -50°C to +50°C, while maintaining the brightness of colors and the internal structure of the concrete;

- compared to natural materials stamped concrete is a low cost and longer service life;

- the main stages of production and laying is quite simple and does not require special skills and knowledge.

Training places and formworkto produce concrete printing, choose a warm dry day. The temperature should not be below +5°C minimum humidity will promote rapid drying of the workpieces. With the help of pegs and ropes enclose the area selected for coverage.

In the selected areas, remove the top layer of soil. If the coating is intended only for pedestrians – remove a layer of about 158 cm. For the site, which provides vehicular traffic, the soil removed to a depth of 20 cm obtained In the formwork poured a mixture of crushed stone and sand. Received the pillow thoroughly tamped. On top of the compacted cushion of stacked polyethylene film with an overlap of about 10 cm, put on top of the reinforcing mesh.

KneadingFor the production of concrete printing is best suited Portland cement M400 or M500 with the addition of various plasticizers. For decorative coatings in concrete it is recommended to add polypropylene fibre.

One cubic meter of concrete is 0.6 kg this Supplement. Polypropylene fiber significantly improves durability of the finished concrete and prevents the formation of cracks and chips on its surface. For the manufacture of decorative concrete with your hands requires the following components:

- three parts sand;

- three parts gravel fractions of 5-20 mm;

- plasticizer S-3 is 0.5% on a dry matter basis. Note that the plasticizer is added to the mixture in an aqueous solution;

- Portland cement M-400;

- polypropylene fiber of 0.6 kg per 1 cub.m.

Around the perimeter of the formwork surface smooth corner trowel.Applying a decorative layerBefore applying the upper decorative layer working surface is treated with a fixative. About 70% of the required quantity of binder is applied manually on the matte surface of the concrete and smoothing aluminum trowel. Then scatter the remainder of the binder and smooth down the surface with steel trowel.

The following step – application of the hardener. This component represents a mixture of resistant pigments, filler and binder component. Each layer of the curing agent is rubbed into the surface until the outer layer of the printed concrete will not be smooth and evenly colored.

The creation of the terrain surface or simulationIf your goal was to make the surface of the stamped concrete relief imitating stone, brick or Board after application of the hardener wet surface should be treated with special presses, which give the concrete the required shape.

This operation must be performed with the still uncured concrete, while the surface is easy to push of your finger.Layingthe Prepared matrix is placed on the surface of the concrete. The first number is usually placed along the outside edge of the formwork. To achieve the perfectly smooth lines of the matrix should be closely pressed against each other. For final curing of decorative concrete you will need about two days. After that the concrete surface is cleaned, remove excess material with a stiff brush with a long NAP. The surface is washed and dried.

Applying an acrylic layerFor finishing of decorative concrete at its surface is applied a protective acrylic layer. This safeguard will reduce the harmful effects of the environment and will significantly increase the lifetime of printed concrete.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Manufacture of concrete with your hands requires special attention, careful selection of components and the exact observance of technology. But this coating perfectly decorate the interior of your home or garden and will add to the architectural ensemble of your home its own unique flavor. published

Source: tehno-beton.ru/beton/vidy/pechatnyj-texnologiya.html

Social zombies: looking good does not mean internal happiness

How to make the right drainage garden plot