445

Singapore scientists have created a concrete future

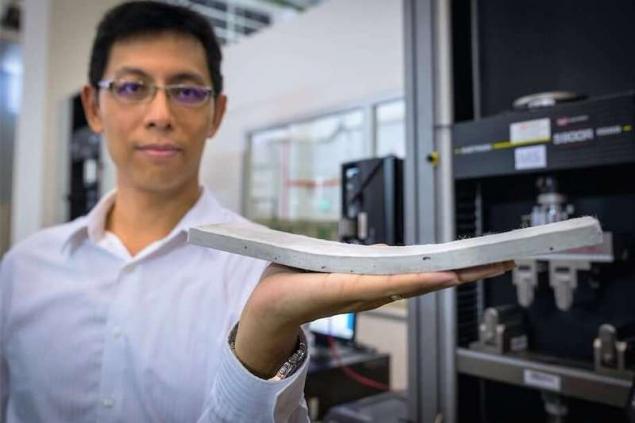

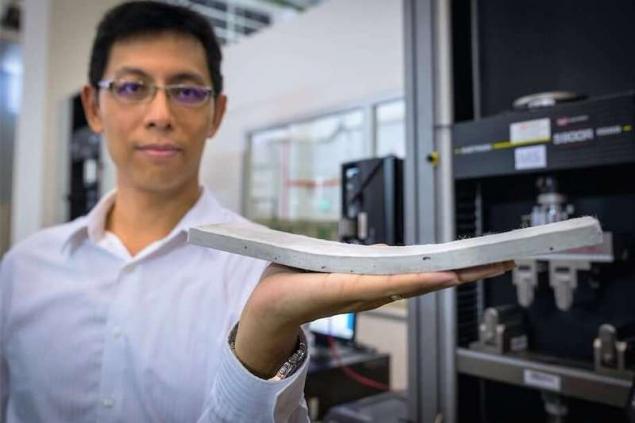

Concrete, though, and is one of the most common building materials, it has one very unpleasant drawback. Over time, it severely dries out, cracks and eventually may break under strong pressure. Scientists from Nanyang technological University (Singapore) figured out how to harden this material, instead of breaking it bent.

Typically, concrete made from a mixture of cement, gravel, sand and water. ConFlexPave, the material, which was created by Singapore scientists, has another component — polymeric microfibers. They are thinner than a human hair, but when added to concrete can harden it by a uniform distribution of load exerted pressure.

As a result, the creators ConFlexPave, "he is as flexible as metal, and is able to withstand the loads at least two times the maximum load for plain concrete." In addition, the creators claim that their material has a high degree of anti-slip effect.

The new material can be produced at the plant and then delivered to the construction site. In this case not only facilitates the work of builders who usually have to mix concrete on the spot but also made the material in about half the time faster. In case of damage plates over time, they can if desired be replaced (such a practice is the place to be and with the usual concrete slabs).

To date, testing new material ConFlexPave was conducted only in the laboratory. In this case used a plate the size of a regular table. Next, the researchers plan to use full size slabs of this material for the construction of new facilities within the University campus. First in line are the pedestrian and vehicular paths. A test of their strength will be in the next three years. published

Source: hi-news.ru/technology/singapurskie-uchenye-sozdali-beton-budushhego.html

Typically, concrete made from a mixture of cement, gravel, sand and water. ConFlexPave, the material, which was created by Singapore scientists, has another component — polymeric microfibers. They are thinner than a human hair, but when added to concrete can harden it by a uniform distribution of load exerted pressure.

As a result, the creators ConFlexPave, "he is as flexible as metal, and is able to withstand the loads at least two times the maximum load for plain concrete." In addition, the creators claim that their material has a high degree of anti-slip effect.

The new material can be produced at the plant and then delivered to the construction site. In this case not only facilitates the work of builders who usually have to mix concrete on the spot but also made the material in about half the time faster. In case of damage plates over time, they can if desired be replaced (such a practice is the place to be and with the usual concrete slabs).

To date, testing new material ConFlexPave was conducted only in the laboratory. In this case used a plate the size of a regular table. Next, the researchers plan to use full size slabs of this material for the construction of new facilities within the University campus. First in line are the pedestrian and vehicular paths. A test of their strength will be in the next three years. published

Source: hi-news.ru/technology/singapurskie-uchenye-sozdali-beton-budushhego.html