746

The unique technology allows to convert carbon dioxide into the concrete

Imagine a world in which there is practically no concrete. Will this possible in principle? Concrete everywhere - on our roads and tracks, in our homes, bridges and buildings. Over the past 200 years it has become in every sense the foundation for much of our planet. But the production of cement, which when mixed with water forms a binder in concrete, is also one of the largest sources of greenhouse gas emissions. In general, concrete comes out to about 5 per cent of greenhouse gases on our planet.

Another big source of carbon dioxide emissions is the smoke emitted from the smokestacks at power plants around the world. Industrial carbon emissions are the largest source of greenhouse gases in the world.

interdisciplinary research team from Los Angeles working on a unique solution that can help to eliminate these sources of greenhouse gases. In their plans - the creation of a closed process, including carbon capture at power plants pipes and its use in the creation of a new building material - uglekislobetona CO2NCRETE (Eng «concrete» -. Concrete) - with the use of 3D-printing technology

.

"This technology takes something that we were looked upon as a nuisance - carbon dioxide, and turns it into something of value," - says JR DeShazo, public policy professor at ULCA Luskin School of Public Affairs and Director of the School of Innovation Center <.. br> "I decided to take part in this project, because it can change the rules of the game for climate policy," - says DeShazo. - "This technology is aimed at addressing the problem of global climate change, which is one of the biggest challenges that society is facing now and will face in the next century»

.

This is not the first attempt to capture carbon dioxide from power plant emissions. Similar attempts have been made before, but always there was a problem - what to do with carbon dioxide after his capture

. "The approach that we are trying to suggest is to consider carbon dioxide as a resource - a resource that you can use again," - explains the head of the research team Professor Sant Gora. - "While cement production leads to an increase in carbon dioxide emissions, as well as the production of coal or natural gas, CO2 re-use for the manufacture of building materials, which would be a new kind of cement - yet unrealized opportunity»

.

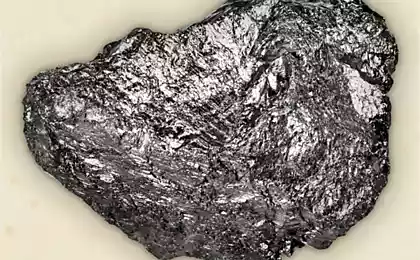

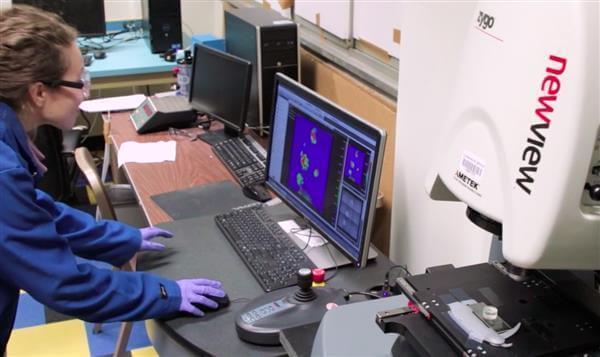

Until now, new building material could be obtained only in the laboratory, forming it into a small "bumps" with the use of 3D-printing. "We have a fundamental proof that we can do it," - says DeShazo. - "But we have to increase the volume of the resulting material, and then to think about commercialization. Demonstration of technology in the laboratory - one task, the demonstration in the field -. the other »

"We can demonstrate the process of combining lime and carbon dioxide to produce a material like cement," - says Sant. - "The main challenge that we see is that we are not just trying to develop a building material. We are trying to develop a technology solution, integrated technology that comes directly from CO2 to the finished product. »

"3D- printing is already used for some time in biomedicine," - says St. - "but when you use it in medicine, you are interested in spatial resolution and accuracy. The construction of all these things are very important, but not on such a scale. There is a size problem, because instead of typing something in length of 5 centimeters, we want to be able to print a beam of 5 meters in length. Scalability size is a very important part of our work. »

Another problem - to convince stakeholders of the company that offered revolutionary technology is beneficial not only for the planet, but also for them

. "This technology could change the industry related to power, and turn the smoke from the chimneys into a resource that can be used to create the city to expand the road system," - concludes DeShazo. "As one of the leading universities in the world, we see ourselves striving to develop technologies that are on the one hand could be considered weird, but it is very quickly becoming a reality," - adds Sant.

Another big source of carbon dioxide emissions is the smoke emitted from the smokestacks at power plants around the world. Industrial carbon emissions are the largest source of greenhouse gases in the world.

interdisciplinary research team from Los Angeles working on a unique solution that can help to eliminate these sources of greenhouse gases. In their plans - the creation of a closed process, including carbon capture at power plants pipes and its use in the creation of a new building material - uglekislobetona CO2NCRETE (Eng «concrete» -. Concrete) - with the use of 3D-printing technology

.

"This technology takes something that we were looked upon as a nuisance - carbon dioxide, and turns it into something of value," - says JR DeShazo, public policy professor at ULCA Luskin School of Public Affairs and Director of the School of Innovation Center <.. br> "I decided to take part in this project, because it can change the rules of the game for climate policy," - says DeShazo. - "This technology is aimed at addressing the problem of global climate change, which is one of the biggest challenges that society is facing now and will face in the next century»

.

This is not the first attempt to capture carbon dioxide from power plant emissions. Similar attempts have been made before, but always there was a problem - what to do with carbon dioxide after his capture

. "The approach that we are trying to suggest is to consider carbon dioxide as a resource - a resource that you can use again," - explains the head of the research team Professor Sant Gora. - "While cement production leads to an increase in carbon dioxide emissions, as well as the production of coal or natural gas, CO2 re-use for the manufacture of building materials, which would be a new kind of cement - yet unrealized opportunity»

.

Until now, new building material could be obtained only in the laboratory, forming it into a small "bumps" with the use of 3D-printing. "We have a fundamental proof that we can do it," - says DeShazo. - "But we have to increase the volume of the resulting material, and then to think about commercialization. Demonstration of technology in the laboratory - one task, the demonstration in the field -. the other »

"We can demonstrate the process of combining lime and carbon dioxide to produce a material like cement," - says Sant. - "The main challenge that we see is that we are not just trying to develop a building material. We are trying to develop a technology solution, integrated technology that comes directly from CO2 to the finished product. »

"3D- printing is already used for some time in biomedicine," - says St. - "but when you use it in medicine, you are interested in spatial resolution and accuracy. The construction of all these things are very important, but not on such a scale. There is a size problem, because instead of typing something in length of 5 centimeters, we want to be able to print a beam of 5 meters in length. Scalability size is a very important part of our work. »

Another problem - to convince stakeholders of the company that offered revolutionary technology is beneficial not only for the planet, but also for them

. "This technology could change the industry related to power, and turn the smoke from the chimneys into a resource that can be used to create the city to expand the road system," - concludes DeShazo. "As one of the leading universities in the world, we see ourselves striving to develop technologies that are on the one hand could be considered weird, but it is very quickly becoming a reality," - adds Sant.

18.05. Royal Hill, a relative of the Big Apple and the City of Light

The key to healing: How the past is embodied in a living organism