159

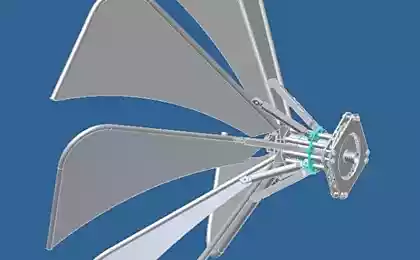

Innovative wind generator from Festo

Windmills offer a great way to harness renewable energy and man has been using them for nearly two centuries, but who said it was the only way to catch the wind?

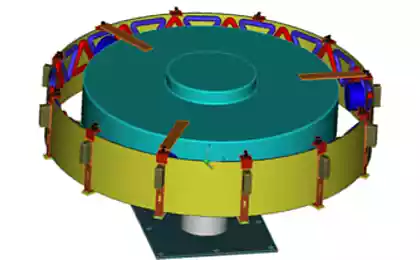

Festo, a manufacturer of automation systems, offers a new type of technology for working with the wind, the so-called Dual Wing Generator, in which the rotor blades instead of the traditional, are shaped like bird wings.

This once again calls into question that the traditional shape of the propeller blade is the most efficient pinnacle of wind capture technology.

After all, birds flap their wings to get enough energy to travel through the air, so it makes sense to look at them and learn from them.

While the bird, working with its wings, moves itself, the Dual Wing Generator stays in place, collecting kinetic energy from the airflow using the reverse principle. The force of the wind creates a lift that swings the "wings" of the installation up and down, and then these movements are converted into rotation.

With the help of an electric generator, mechanical energy is converted into electric current.

Four wings are located on either side of the central column. Two upper and two lower wings, which are paired on one axis driven by the engine. The axes, in turn, are fixed on sliders moving along the guides.

When the wind blows, the sliders move in opposite directions: the two upper wings move up, and the two lower wings, respectively, down. A pair of wings on one side forms a functional unit whose aerodynamic characteristics, together with the intricate mechanics of the device, allow generating energy in an optimal way. When the system is at an extreme point, the servo drive deploys the wings and they automatically begin to move towards each other.

Their active rotation means that the wings are always set so that air currents are directed at them at an optimal angle. This allows the adaptive system to achieve optimal energy production with a very high level of efficiency.

The entire mechanism used to convert wind energy into electricity is integrated into the central column of the DualWingGenerator. The column also contains a sensor system that helps to optimize mechanical movement and allows you to adapt to wind conditions for the most energy efficient operation.

The system determines the direction of the airflow, and the central column automatically turns and always directs the wings made of carbon fiber at right angles to the approaching wind.

Thus, the air flow acts on the aerodynamic profile of the wings, which are always installed at the appropriate angle by means of a servo drive. This leads to the movement of sliders with wings mounted on them. Movements in different directions are synchronized using a gear belt that transmits force to two bearing shafts with one-way rotation.

Then two gear pulleys through the second gear belt transmit the rotation to the generator, which generates electricity.

In this way, wind energy first generates kinetic energy, which is then converted into electrical energy.

Festo tested the efficiency of the Dual Wing Generator along with conventional wind turbines of similar size. The team says the system achieved “remarkable results compared to small wind farms,” demonstrating a hydromechanical efficiency of 45% at wind speeds ranging from 4 to 8 meters per second, with a maximum theoretical (Betz’s law) of 59.3.

While there is no word yet on the product’s market launch, Festo is continuing to develop the technology and is talking about the possible use of DualWingGenerator as small wind turbines on rooftops or for the production of compressed air or water.

Source: facepla.net

Cuba heads the 67-th session of world health Assembly

Chronodiet - food in accordance with the biological rhythms of the body