472

Stone paper is a durable and eco-friendly

Manufacture of paper, but damaging to the environment. Trees are felled, polluted water, consumes large amounts of energy. In light of preserving the green cover of the planet is very relevant are alternative methods of producing paper. Therefore, the manufacturers interested in the manufacture of economaki of stone.

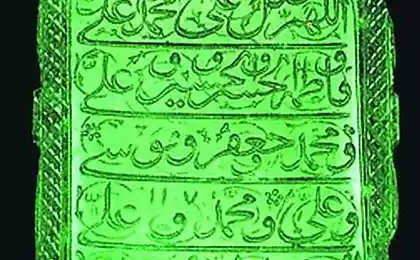

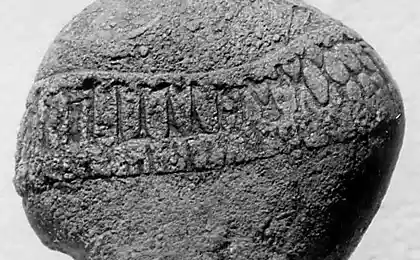

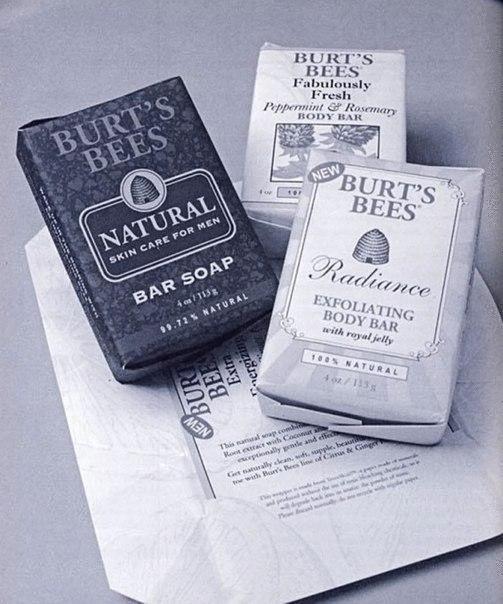

The ecological paper is calcium carbonate. Note that it is contained in a conventional paper, but in smaller quantities. Calcium carbonate is produced from minerals, which are often discarded in the extraction of the raw materials used for the construction industry. That is, for the production of new papers in the course are waste limestone, marble and so on. The rock is ground until obtained a thin chalky dust. It adds a non-toxic synthetic resin HDPE is high density polyethylene, – to bind dust particles. This substance is 80% calcium carbonate and 20% HDPE. The output from it is white, smooth and soft paper, resistant to water and abrasion. It has no acids or chlorine, it is completely safe for the environment. This paper is irestaurant and almost never breaks. It is suitable for outdoor use, especially if it is supplemented with UV protection.

Note that to produce a ton of regular paper requires about 20 trees. In the process of its production is consumed 38000 kJ of energy, pollute the water in an amount of 73 cubic meters. In addition, use bleach, it happens in the development of recycled paper. For her, however, cut down fewer trees – four for one ton of finished material. Manufacturing recycled paper consumes about 23,000 kJ of energy and pollutes approximately 41 cubic meter of water. And clean, and in recycled paper contains 30% calcium carbonate. To manufacture a tonne of paper made of stone, don't need trees, consumes half the energy required for the production of recycled paper, and dirty water. This paper does not need bleaching. Mineral paper is eco-friendly in all respects. Recycle it with plastic and plain paper. Under the influence of sunlight resin HDPE dissolves in the course of the year, and the calcium carbonate is returned to the original solid form that is natural for the environment. If you destroy mineral paper factories for recycling, it will not be in combustion emit toxic substances.

The producers no lack of raw material for mineral paper, since calcium carbonate is about 70% of the total number of minerals on Earth. Currently, there are several brands to produce paper from stone FiberStone for example, Terraskin, and Rockstock..

P. S. And remember, just changing your mind — together we change the world! ©

Source: vk.com/wiki_inventions?z=photo-56414092_372972014%2Falbum-56414092_00%2Frev

The ecological paper is calcium carbonate. Note that it is contained in a conventional paper, but in smaller quantities. Calcium carbonate is produced from minerals, which are often discarded in the extraction of the raw materials used for the construction industry. That is, for the production of new papers in the course are waste limestone, marble and so on. The rock is ground until obtained a thin chalky dust. It adds a non-toxic synthetic resin HDPE is high density polyethylene, – to bind dust particles. This substance is 80% calcium carbonate and 20% HDPE. The output from it is white, smooth and soft paper, resistant to water and abrasion. It has no acids or chlorine, it is completely safe for the environment. This paper is irestaurant and almost never breaks. It is suitable for outdoor use, especially if it is supplemented with UV protection.

Note that to produce a ton of regular paper requires about 20 trees. In the process of its production is consumed 38000 kJ of energy, pollute the water in an amount of 73 cubic meters. In addition, use bleach, it happens in the development of recycled paper. For her, however, cut down fewer trees – four for one ton of finished material. Manufacturing recycled paper consumes about 23,000 kJ of energy and pollutes approximately 41 cubic meter of water. And clean, and in recycled paper contains 30% calcium carbonate. To manufacture a tonne of paper made of stone, don't need trees, consumes half the energy required for the production of recycled paper, and dirty water. This paper does not need bleaching. Mineral paper is eco-friendly in all respects. Recycle it with plastic and plain paper. Under the influence of sunlight resin HDPE dissolves in the course of the year, and the calcium carbonate is returned to the original solid form that is natural for the environment. If you destroy mineral paper factories for recycling, it will not be in combustion emit toxic substances.

The producers no lack of raw material for mineral paper, since calcium carbonate is about 70% of the total number of minerals on Earth. Currently, there are several brands to produce paper from stone FiberStone for example, Terraskin, and Rockstock..

P. S. And remember, just changing your mind — together we change the world! ©

Source: vk.com/wiki_inventions?z=photo-56414092_372972014%2Falbum-56414092_00%2Frev