623

Clay oven Arkaim — forgotten technology

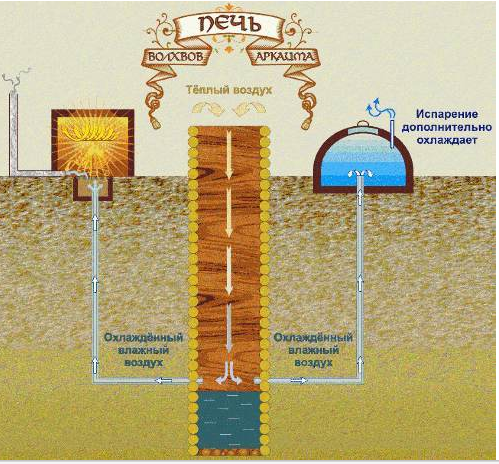

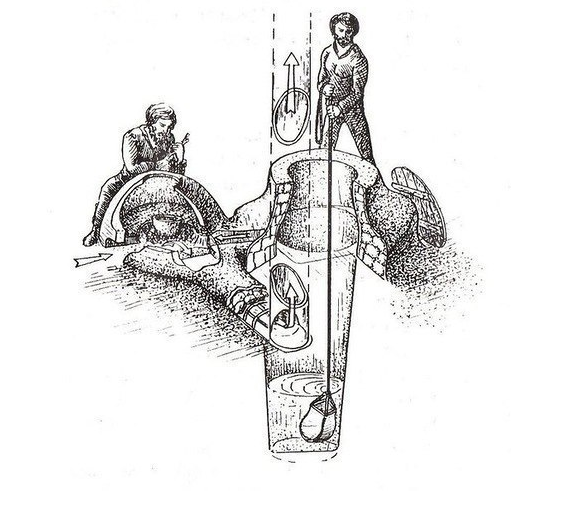

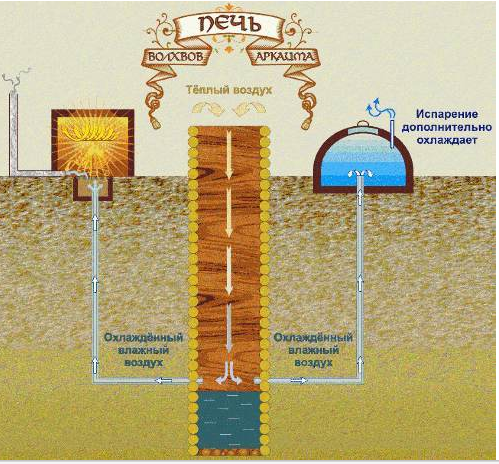

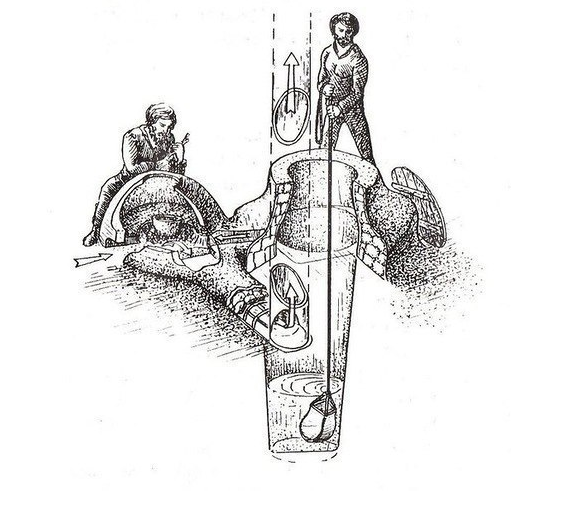

The article describes an interesting design Arkaim furnace. With the combination of the hearth and well created strong and natural air draft. The air entering the pillar of the well (shown below), was cooled located in the column of well water and fed into the furnace.

It is known that for melting of bronze, a relatively high temperature which cannot be obtained without the filing of a large volume of air to the point of combustion.

"The ancient Aryans were provided with sewers. Moreover, in each dwelling there was a well, an oven and a small dome-shaped vault. Why? All ingenious is simple. We all know that from well, if to look at him, always pulling cool air. So, in Aryan the stove this cool air, passing through an earthen pipe, creating thrust with such force that she was allowed to melt bronze without the use of bellows! This was the furnace in each dwelling, and the ancient Smiths had only to hone their skills, competing in this art! Another earthen pipe leading into the vault, provided it lowered temperature". (Rites of Love Chapter Arkaim — Academy of the wise men, p. 46).

Next to the stove there was a well, with the ash pit of the furnace was connected with the well through the ground arranged in a blower channel. Conducted by archaeologists experiments showed that Arkaim "miracle-oven" can maintain a temperature sufficient not only to melt the bronze, but also for smelting of copper from ore (1200-1500 degrees!). Thanks to the air duct connecting the furnace with the adjacent well of a five-meter depth, in an oven, there is thrust, providing the required temperature. Thus, the ancient inhabitants of Arkaim embodied in the reality of mythological ideas about water that give birth to fire.

No nonsense here, no, because cold air supply was used in the ancient furnaces of Europe:

A quick way of turning iron into steel was developed in 1856 by the Englishman G. Bessemer. He proposed to blow molten liquid iron by air is based on the fact that the oxygen will unite with the carbon and carry it in the form of gas. Bessemer feared, as if the air is not cooled the iron. In fact, it was the opposite — the cast iron is not only cooled, but even more heated. Unexpected, isn't it? And the reason is simple: when oxygen of the air with various elements contained in the iron, for example, silicon or manganese, allocates a considerable amount of heat.

By the way, most closely to the mystery of a miracle-furnaces came our 18th century Russian scientist Mikhail Lomonosov. When visiting Ural mines, he noticed cool air coming from the mines and became interested in this phenomenon. Here he writes about it the same Vladimir E. Grum-Grzhimailo, a job which I found in the attic Alexander Spirin: Lomonosov naming his predecessor, he wrote in the Preface to his book:

"In his thesis "On the free movement of air, in mines note" (1742) he gave a crystal clear idea about the movement of air in mines and chimneys. His theory extruding heavy, cold outer air and warm smoke was well learned by the whole world. But there the matter stopped. In further attempts to explain the movement of gas in furnaces confused the word "attraction", is grammatically absurd, for the verb to pull assumes a direct relationship between force and object that stretches. Draught in furnaces and flue pipes is: is the squeezing of warm air smoke heavy air, as rightly pointed out M. V. Lomonosov; never used the word "pull".

The question arises: what force is causing the motion of the cold air up? For example, take the case of two communicating vessels containing water. It is possible to take flexible building level. As if we did not change the height of either end of the hose, the water in both vessels is always at the same level. Could it be the same if in communicating vessels is not liquid, but gas? Yes, if the diameter of the vessels is the same. But if one vessel has a diameter of a decimeter, and another vessel has a diameter of a meter, the gases occupy the same level relative to the surface of the earth? Indeed, in this case it is necessary to consider the pressure of the atmosphere on the upper area of the gas. Take vedruss well connected by the channel with the furnace. The diameter of the outlet channel is 8-12 cm, the cross section of the channel well is the square meter. It is obvious that the pressure of the atmospheric column in the well is greater than the pressure of the atmospheric column in the outlet channel, plus the weight of cold air in the pit, so the cold air will be gently squeezed into the combustion space of the furnace, carrying out the appointment blew.

It turns out that the thrust, the presence of which the modern stoves are so valued in the local community, in the ovens with free movement of gases is a harmful phenomenon, since it involves the uncontrolled release of valuable heat into the surrounding space and the permanent loss of up to 80%, which also means that up to 80% of the forest cut down and burned in vain. Disturbed ecology of the soil and atmosphere, as are harmful substances due to incomplete combustion of the fuel, increasing the carbon dioxide content in the air increases the greenhouse effect. To eliminate harmful phenomena thrust vedrussky furnace, the outlet channel from the furnace it is necessary to arrange in the lower part, in the area of cold air. Thus, the hot gases and the hot air circulating in the upper compartment of the furnace does not output, and accumulating ever-increasing heat. So where does temperature melting metals. Plays well out of the combustion chamber the mixture of cool air and a lower hot gas captured by the flow. When he reached the top of the pipe, the gases are cooled and finally discharged to the outside barely warm, actually, as it was recorded by three scientists from the Yaroslavl Institute, studying baking Alexander Spirin.

Modern furnace designers that use research and development Professor Grum-Grzhimailo, I only know Igor Kuznetsov, but he certainly does not use in their designs of well principle, although it has achieved high performance in their designs of furnaces.published by P. S. And remember, only by changing their consumption — together we change the world! © econet

Source: vk.com/gnezdo_paranoika?w=wall-38598449_113687

It is known that for melting of bronze, a relatively high temperature which cannot be obtained without the filing of a large volume of air to the point of combustion.

"The ancient Aryans were provided with sewers. Moreover, in each dwelling there was a well, an oven and a small dome-shaped vault. Why? All ingenious is simple. We all know that from well, if to look at him, always pulling cool air. So, in Aryan the stove this cool air, passing through an earthen pipe, creating thrust with such force that she was allowed to melt bronze without the use of bellows! This was the furnace in each dwelling, and the ancient Smiths had only to hone their skills, competing in this art! Another earthen pipe leading into the vault, provided it lowered temperature". (Rites of Love Chapter Arkaim — Academy of the wise men, p. 46).

Next to the stove there was a well, with the ash pit of the furnace was connected with the well through the ground arranged in a blower channel. Conducted by archaeologists experiments showed that Arkaim "miracle-oven" can maintain a temperature sufficient not only to melt the bronze, but also for smelting of copper from ore (1200-1500 degrees!). Thanks to the air duct connecting the furnace with the adjacent well of a five-meter depth, in an oven, there is thrust, providing the required temperature. Thus, the ancient inhabitants of Arkaim embodied in the reality of mythological ideas about water that give birth to fire.

No nonsense here, no, because cold air supply was used in the ancient furnaces of Europe:

A quick way of turning iron into steel was developed in 1856 by the Englishman G. Bessemer. He proposed to blow molten liquid iron by air is based on the fact that the oxygen will unite with the carbon and carry it in the form of gas. Bessemer feared, as if the air is not cooled the iron. In fact, it was the opposite — the cast iron is not only cooled, but even more heated. Unexpected, isn't it? And the reason is simple: when oxygen of the air with various elements contained in the iron, for example, silicon or manganese, allocates a considerable amount of heat.

By the way, most closely to the mystery of a miracle-furnaces came our 18th century Russian scientist Mikhail Lomonosov. When visiting Ural mines, he noticed cool air coming from the mines and became interested in this phenomenon. Here he writes about it the same Vladimir E. Grum-Grzhimailo, a job which I found in the attic Alexander Spirin: Lomonosov naming his predecessor, he wrote in the Preface to his book:

"In his thesis "On the free movement of air, in mines note" (1742) he gave a crystal clear idea about the movement of air in mines and chimneys. His theory extruding heavy, cold outer air and warm smoke was well learned by the whole world. But there the matter stopped. In further attempts to explain the movement of gas in furnaces confused the word "attraction", is grammatically absurd, for the verb to pull assumes a direct relationship between force and object that stretches. Draught in furnaces and flue pipes is: is the squeezing of warm air smoke heavy air, as rightly pointed out M. V. Lomonosov; never used the word "pull".

The question arises: what force is causing the motion of the cold air up? For example, take the case of two communicating vessels containing water. It is possible to take flexible building level. As if we did not change the height of either end of the hose, the water in both vessels is always at the same level. Could it be the same if in communicating vessels is not liquid, but gas? Yes, if the diameter of the vessels is the same. But if one vessel has a diameter of a decimeter, and another vessel has a diameter of a meter, the gases occupy the same level relative to the surface of the earth? Indeed, in this case it is necessary to consider the pressure of the atmosphere on the upper area of the gas. Take vedruss well connected by the channel with the furnace. The diameter of the outlet channel is 8-12 cm, the cross section of the channel well is the square meter. It is obvious that the pressure of the atmospheric column in the well is greater than the pressure of the atmospheric column in the outlet channel, plus the weight of cold air in the pit, so the cold air will be gently squeezed into the combustion space of the furnace, carrying out the appointment blew.

It turns out that the thrust, the presence of which the modern stoves are so valued in the local community, in the ovens with free movement of gases is a harmful phenomenon, since it involves the uncontrolled release of valuable heat into the surrounding space and the permanent loss of up to 80%, which also means that up to 80% of the forest cut down and burned in vain. Disturbed ecology of the soil and atmosphere, as are harmful substances due to incomplete combustion of the fuel, increasing the carbon dioxide content in the air increases the greenhouse effect. To eliminate harmful phenomena thrust vedrussky furnace, the outlet channel from the furnace it is necessary to arrange in the lower part, in the area of cold air. Thus, the hot gases and the hot air circulating in the upper compartment of the furnace does not output, and accumulating ever-increasing heat. So where does temperature melting metals. Plays well out of the combustion chamber the mixture of cool air and a lower hot gas captured by the flow. When he reached the top of the pipe, the gases are cooled and finally discharged to the outside barely warm, actually, as it was recorded by three scientists from the Yaroslavl Institute, studying baking Alexander Spirin.

Modern furnace designers that use research and development Professor Grum-Grzhimailo, I only know Igor Kuznetsov, but he certainly does not use in their designs of well principle, although it has achieved high performance in their designs of furnaces.published by P. S. And remember, only by changing their consumption — together we change the world! © econet

Source: vk.com/gnezdo_paranoika?w=wall-38598449_113687