2936

Axial internal combustion engines

Axial ICE Duke Engine i>

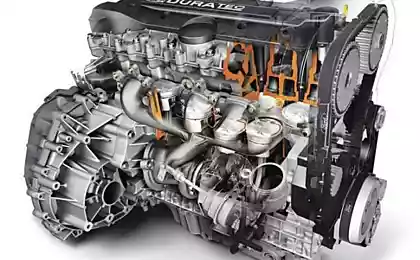

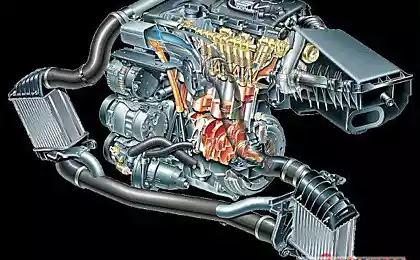

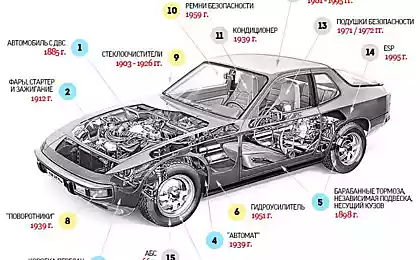

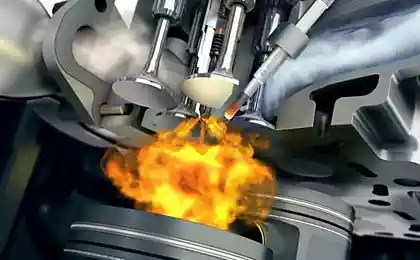

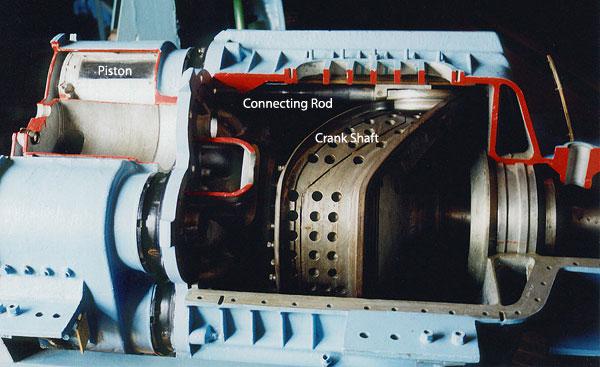

We are used to the classic design of internal combustion engines, which, in essence, has been around for a century. Rapid combustion of the combustible mixture within the cylinder causes an increase of pressure, which pushes the piston. That, in turn, via a connecting rod and crank shaft turns.

Classic ICE i>

If we want to make the engine more powerful, we must first increase the volume of the combustion chamber. By increasing the diameter, we increase the weight of the piston, which has a negative effect on the result. By increasing the length, and we extend the connecting rod, and enlarge the whole engine as a whole. Or you can add the cylinder - which, of course, also increases the volume of the resulting engine.

With such problems faced engineers ICE for the first aircraft. They, after all, come to a beautiful pattern "radial" motor in which the pistons and cylinders arranged in a circle about the shaft at equal angles. Such a system is well-cooled air flow, but it is very much overall. Therefore, the decision to continue the search.

In 1911, Macomber Rotary Engine Company of Los Angeles presented the first аксиальных (Axial) ICE . They are called "tank", motors with swinging (or oblique) washer. The original scheme can accommodate pistons and cylinders around the main shaft and parallel to it. Shaft rotation is due to the swash plate, which in turn put pressure piston rods.

The engine Macomber was 7 cylinders. The manufacturer claims that the engine was capable of operating at speeds from 150 to 1500 rev / min. Thus at 1000 rev / min, it gave 50 hp Being made of the available materials at the time, he weighed 100 kg and had dimensions of 710 × 480 mm. This engine was installed in the airplane pioneer aviator Charles Francis Walsh "Silver Dart Walsh».

Do not stay aside and Soviet engineers . In 1916 appeared the engine designed by AA Mikulin and BS Stechkin, and in 1924 - the engine Starostin. On these engines are aware, perhaps, only the lovers of aviation history. It is known that the detailed tests conducted in 1924, showed increased friction losses and high loads on the individual components of such engines.

Engine Starostin of Aviation Museum in Monino i>

Ingenious and slightly mad engineer, inventor, designer and businessman John DeLorean Zechariah wanted to build a new automobile empire in peak current, and make a totally unique "dream car". We all know the DMC-12 car, which is called a DeLorean. It not only became a star of the screen in the movie "Back to the Future", but also different unique solutions around - from the aluminum body on plexiglass frame and ending with doors "gull-wing". Unfortunately, the economic crisis manufacture of machines not justified. Then DeLorean long pleaded for a false case of drug.

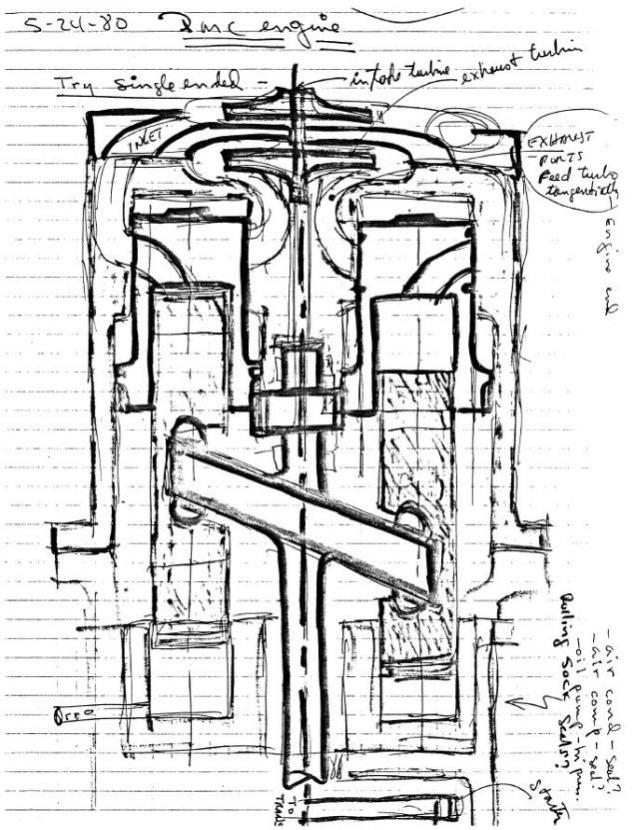

But few know that DeLorean would complement the unique look of the car is also a unique engine - the found after his death were drawings and blueprints of the axial engine. Judging by his letters, he conceived such an engine back in 1954 and began to develop in earnest in 1979. The engine piston DeLorean had three and they are arranged in an equilateral triangle around the shaft. But each piston is a two-way - each of the ends of the piston had to work in his hat.

Drawing from a notebook DeLorean i>

For whatever reasons, the birth did not take place the engine - perhaps because the development of the car from the ground came quite difficult now. On the DMC-12 is 2, 8-liter V6 engine joint development of Peugeot, Renault and Volvo capacity of 130 liters. p. An attentive reader can learn scans of drawings and notes DeLorean here .

Exotic variant of the axial motor - "Engine Trebenta» i>

However, such engines are not widespread - in a big aircraft took place gradually transition to turbojet engines, and cars to this day used the scheme in which the shaft is perpendicular to the cylinders. I wonder just why such a scheme is not caught in motorcycles, where compactness came to just in time. Apparently, they are not able to offer any significant advantages compared with the usual we design. Now these engines exist, but are set mostly in torpedoes - thanks to how well they fit into the cylinder.

option under the name & quot; Cylindrical Energy Module & quot; bilateral pistons. Perpendicular to the piston rods describe a sine wave, moving in undulating surface i>

The main distinguishing feature of the axial ICE - compactness. In addition, its ability to change the degree of compression is included (volume of combustion chamber) simply by changing the angle of the swash plate. Washer swinging shaft because the spherical bearing.

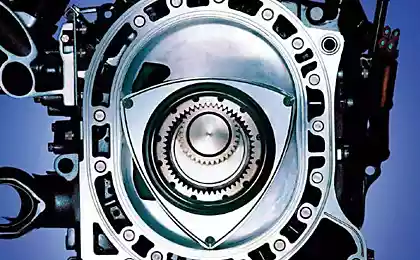

However, the New Zealand company Duke Engines in 2013. introduced its modern version axial engine. These five-cylinder unit, but only three nozzles for fuel injection - no valve. It is also an interesting feature of the engine is the fact that the shaft washer and rotate in opposite directions.

Inside the motor rotates not only the washer and the shaft, but also a set of cylinders with pistons. This allowed to get rid of the valve system - moving the cylinder in the ignition timing just passes the hole where the fuel is injected and where there is a spark plug. In Step Production cylinder passes the outlet gases.

With this system, the number of required candles and injectors are paid less than the number of cylinders. And one has to turn to the amount of the same number of working strokes, like a 6-cylinder engine of conventional design. The weight of the axial motor 30% less.

In addition, engineers from Duke Engines argue that the compression ratio of the engine is superior to conventional counterparts and is 15: 1 for 91-octane gasoline (at the standard automotive internal combustion engine, the figure is typically 11: 1). All these parameters can lead to a reduction in fuel consumption and, as a consequence - to reduce harmful impacts on the environment (or in an increase in engine power - depending on your goals).

Now the company carries engines to commercial use. In this age of mature technologies, diversification, economies of scale, etc. hard to imagine how one can seriously affect the industry. The Duke Engines, apparently. it is also present, so intend to offer their engines for boats, generators and small aircraft.

the demonstration of small vibration motor Duke i>

Source: geektimes.ru/post/251620/