496

How to reduce fuel consumption, or what will become the heart of the car in the future

The efficiency of a modern car with an internal combustion engine is the last and only argument in the battle for the hearts of customers. Modern hybrids are designed and produced as a response to the oil cartels in excessively high prices for gasoline and diesel fuel, repeat the fate of transport with internal combustion engines. Huge investment in the development of the lungs and SeverEnergia lithium-ion batteries has brought unexpected results. The capacity of batteries are in mass production, exceeded the most rational forecasts and exceeded 100 W/kg.

Hybrids have become a major force able to displace competitors and to take the niche of "urban passenger transport".

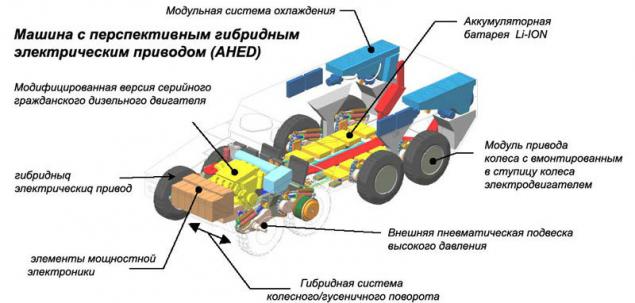

All possible variants of combined systems has gradually been reduced to one — the most simple and reliable. The power plant of this hybrid consists of a combustion engine with Atkinson cycle or diesel with alternator and battery. To the rise in popularity of lithium batteries in such systems, was used adapted acid batteries, metal-nickelhydride and alkaline system.

Battery enough for a few tens of kilometers, had to save every Joule through a complex and expensive system of sensors and controllers. It seemed that a lot of hybrids have been predefined – city "turtle" with a high environmental performance, extremely low fuel consumption of 2-3 liters.

The emergence of more affordable hybrids produced revolutionary changes in the automotive market, but forced to think seriously about the future of the internal combustion engine. Design ideas tried to save the internal combustion engine of a passenger car. The system "start-stop", the electric expansion joints, the booster system on the basis of the capacitor banks allowed to reduce consumption of diesel engine up to 3 liters per hundred, though led to a slight complexity to the design.

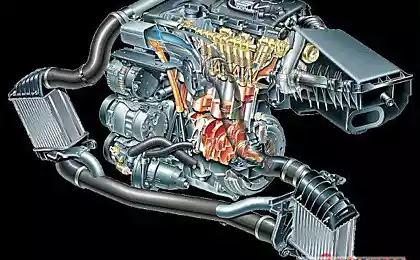

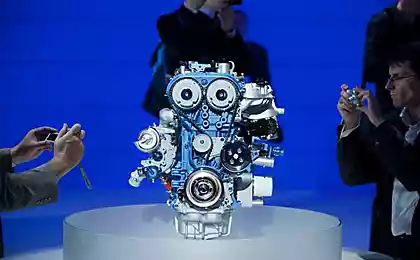

Further improvement of the internal combustion engine, without the introduction of new, more sophisticated, principles of conversion of thermal energy into mechanical energy, has become almost impossible. On the market of passenger transport with internal combustion engine cars became more comfortable, stylish, powerful, but the engine was practically at a standstill.

What saved the engine cars of loss and complete neglect ofthe Widespread tightening of environmental regulations on the content of toxic substances in the exhaust gas, the high price of hydrocarbons has brought new problems for heat engines. Gigantic industrial complexes and technological lines created by global giants of the global auto industry specifically for the construction of transport based on internal combustion engines. Many technological cycles and chains are linked in an intricate network, from raw materials to products to advertising companies. To reconfigure this efficient mechanism for the production of fundamentally new products is expensive and difficult. It is easier to fight for further improvement of internal combustion engines, making them cheaper to produce, unified, reliable, and intricate at the same time. About 80-ies of the last century, the internal combustion engines are widely used microcontrollers and sensors the quality of the combustible mixture. It was the last significant breakthrough in the development of thermal engines. Even if modern methods of management, control and optimization of engine operation will help to improve the combustion process and reduce the loss — this is still not enough to compete with transport on electricity.

Hybrid diesel-electric drives are doomed to complete disappearance, the advantages of such a scheme is sufficient for use in small limited scope. With the drastic cheapening of the cost of lithium batteries the use of capricious and heavy hybrid loses all meaning. The mileage of the car on electricity made up of 300-400km, and much of this stock is excessive. Practice says about the adequacy of 200km. The modern way of life implies that the daily cost of productive time, energy and health to drive more than 2 hours a day are a luxury. Until the complete victory of the electric car remains a little – reducing the cost of lithium batteries is progressing slowly but surely.

A dead end? It is not necessary. This is not the first arrival of electric vehicles in our lives. In the early twentieth century the first samples of electric traction was considered seriously as an alternative no less primitive petrol and steam cars. The victory remained with the internal combustion engine.

One of the most important factors that guarantee further development of the internal combustion engine of passenger cars, is the lack of real alternatives to internal combustion engines used in the world transport system. The production of internal combustion engines and associated systems is inextricably linked with a parallel production of consumables engine oils, coolants, spark plugs, a huge number of spare parts and replaceable units. Is a huge business. It will be hard to maintain the monopoly of the internal combustion engine.

In 2015. significantly reduced prices for oil and oil products. If the cost of gasoline and diesel fuel will decrease similarly to the price of oil, the widely advertised low cost of electric vehicle mileage will be not so convincing.

The main component in the cost of electric vehicles is the cost of the system of accumulation of electricity. If you calculate the battery life, its depreciation, it turns out that the cost of electric vehicle mileage is not so small as it might seem at first glance. Mass production of electric vehicles equipped with lithium batteries, is possible only if the increase of two orders of magnitude the number of batteries based on lithium. But the reserves of this metal is not as huge as the oil fields and their development requires considerable resources.

What are the prospects of development of internal combustion enginesnow on the market are gaining popularity of the model class "A" and "b", In which stated the actual fuel consumption of 2.9 to 3.5 litres of diesel per 100 kilometers. A lot or a little? You may recall the development of the AUDI's in the 80-ies of the last century, obtained in the experimental runs of a prototype flow rate of 1.5 liters per hundred.

Surprisingly, the ice there is scope for further reduction in fuel consumption:

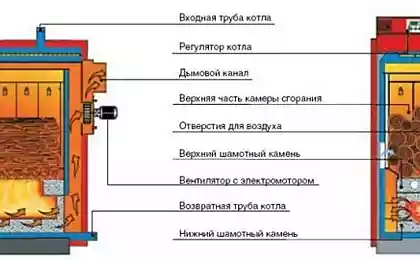

System with direct fuel injection and re-use of exhaust energy. Structurally, these motors have incorporated all the advantages and benefits of diesel and petrol engines. The possibility of using energy of the exhaust gases allows to increase the efficiency to unrealistic 55-60%. The cost of these engines while tens of thousands of euros, weight and overall dimensions do not allow to apply them to passenger transport. Almost forgotten and no one seriously do not perceive the scheme with mechanical energy storage. The idea of this design is to use the system of the super flywheel and a low-power internal combustion engine operating in an extremely narrow range of engine speeds. The last factor allows you to maximize the efficiency of the thermal cycle, and supercapital takes the entire load. The online flywheel drive hundreds of times greater than the resource of any battery. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.n-age.org.ua/texnologii/kak-umenshit-rasxod-topliva-ili-chto-stanet-serdcem-legkovogo-avtomobilya-v-budushhem.html

Hybrids have become a major force able to displace competitors and to take the niche of "urban passenger transport".

All possible variants of combined systems has gradually been reduced to one — the most simple and reliable. The power plant of this hybrid consists of a combustion engine with Atkinson cycle or diesel with alternator and battery. To the rise in popularity of lithium batteries in such systems, was used adapted acid batteries, metal-nickelhydride and alkaline system.

Battery enough for a few tens of kilometers, had to save every Joule through a complex and expensive system of sensors and controllers. It seemed that a lot of hybrids have been predefined – city "turtle" with a high environmental performance, extremely low fuel consumption of 2-3 liters.

The emergence of more affordable hybrids produced revolutionary changes in the automotive market, but forced to think seriously about the future of the internal combustion engine. Design ideas tried to save the internal combustion engine of a passenger car. The system "start-stop", the electric expansion joints, the booster system on the basis of the capacitor banks allowed to reduce consumption of diesel engine up to 3 liters per hundred, though led to a slight complexity to the design.

Further improvement of the internal combustion engine, without the introduction of new, more sophisticated, principles of conversion of thermal energy into mechanical energy, has become almost impossible. On the market of passenger transport with internal combustion engine cars became more comfortable, stylish, powerful, but the engine was practically at a standstill.

What saved the engine cars of loss and complete neglect ofthe Widespread tightening of environmental regulations on the content of toxic substances in the exhaust gas, the high price of hydrocarbons has brought new problems for heat engines. Gigantic industrial complexes and technological lines created by global giants of the global auto industry specifically for the construction of transport based on internal combustion engines. Many technological cycles and chains are linked in an intricate network, from raw materials to products to advertising companies. To reconfigure this efficient mechanism for the production of fundamentally new products is expensive and difficult. It is easier to fight for further improvement of internal combustion engines, making them cheaper to produce, unified, reliable, and intricate at the same time. About 80-ies of the last century, the internal combustion engines are widely used microcontrollers and sensors the quality of the combustible mixture. It was the last significant breakthrough in the development of thermal engines. Even if modern methods of management, control and optimization of engine operation will help to improve the combustion process and reduce the loss — this is still not enough to compete with transport on electricity.

Hybrid diesel-electric drives are doomed to complete disappearance, the advantages of such a scheme is sufficient for use in small limited scope. With the drastic cheapening of the cost of lithium batteries the use of capricious and heavy hybrid loses all meaning. The mileage of the car on electricity made up of 300-400km, and much of this stock is excessive. Practice says about the adequacy of 200km. The modern way of life implies that the daily cost of productive time, energy and health to drive more than 2 hours a day are a luxury. Until the complete victory of the electric car remains a little – reducing the cost of lithium batteries is progressing slowly but surely.

A dead end? It is not necessary. This is not the first arrival of electric vehicles in our lives. In the early twentieth century the first samples of electric traction was considered seriously as an alternative no less primitive petrol and steam cars. The victory remained with the internal combustion engine.

One of the most important factors that guarantee further development of the internal combustion engine of passenger cars, is the lack of real alternatives to internal combustion engines used in the world transport system. The production of internal combustion engines and associated systems is inextricably linked with a parallel production of consumables engine oils, coolants, spark plugs, a huge number of spare parts and replaceable units. Is a huge business. It will be hard to maintain the monopoly of the internal combustion engine.

In 2015. significantly reduced prices for oil and oil products. If the cost of gasoline and diesel fuel will decrease similarly to the price of oil, the widely advertised low cost of electric vehicle mileage will be not so convincing.

The main component in the cost of electric vehicles is the cost of the system of accumulation of electricity. If you calculate the battery life, its depreciation, it turns out that the cost of electric vehicle mileage is not so small as it might seem at first glance. Mass production of electric vehicles equipped with lithium batteries, is possible only if the increase of two orders of magnitude the number of batteries based on lithium. But the reserves of this metal is not as huge as the oil fields and their development requires considerable resources.

What are the prospects of development of internal combustion enginesnow on the market are gaining popularity of the model class "A" and "b", In which stated the actual fuel consumption of 2.9 to 3.5 litres of diesel per 100 kilometers. A lot or a little? You may recall the development of the AUDI's in the 80-ies of the last century, obtained in the experimental runs of a prototype flow rate of 1.5 liters per hundred.

Surprisingly, the ice there is scope for further reduction in fuel consumption:

System with direct fuel injection and re-use of exhaust energy. Structurally, these motors have incorporated all the advantages and benefits of diesel and petrol engines. The possibility of using energy of the exhaust gases allows to increase the efficiency to unrealistic 55-60%. The cost of these engines while tens of thousands of euros, weight and overall dimensions do not allow to apply them to passenger transport. Almost forgotten and no one seriously do not perceive the scheme with mechanical energy storage. The idea of this design is to use the system of the super flywheel and a low-power internal combustion engine operating in an extremely narrow range of engine speeds. The last factor allows you to maximize the efficiency of the thermal cycle, and supercapital takes the entire load. The online flywheel drive hundreds of times greater than the resource of any battery. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.n-age.org.ua/texnologii/kak-umenshit-rasxod-topliva-ili-chto-stanet-serdcem-legkovogo-avtomobilya-v-budushhem.html