862

A new method of 3D printing in 25-100 times faster than traditional

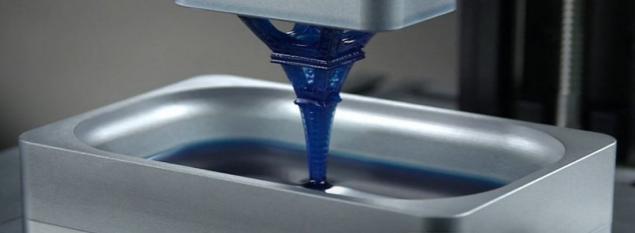

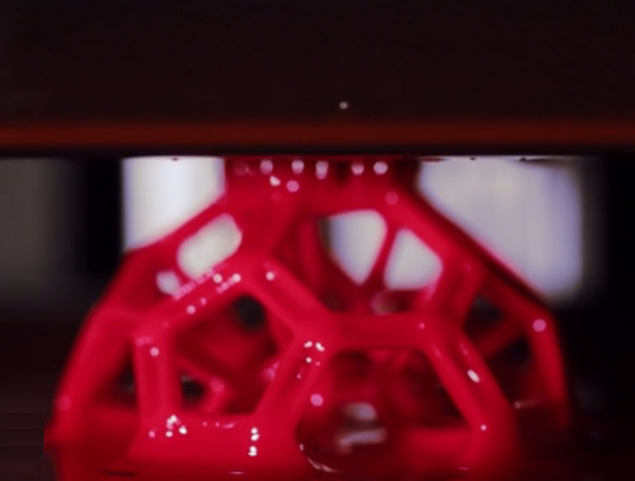

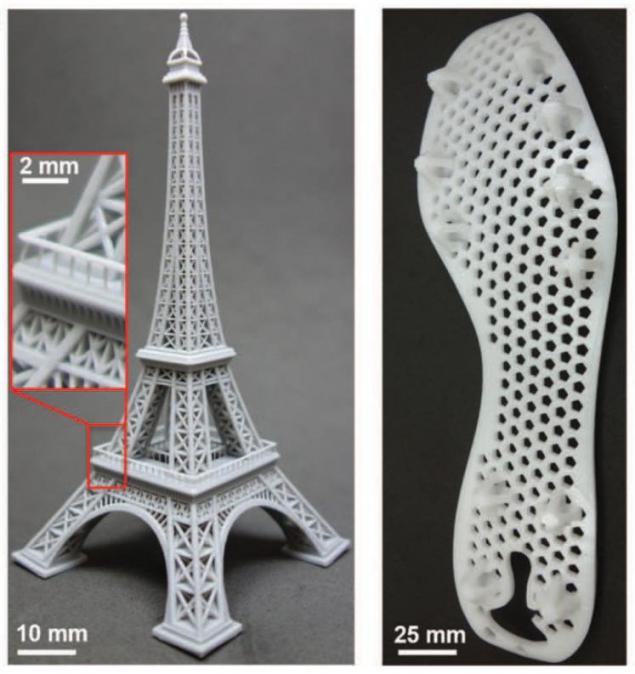

3D printing method, proposed by Californian company Carbon 3D could become a "killer" of the traditional method, familiar to many. The thing is that the new technology is 25-100 times faster than previous methods for creating 3D objects. The company develops its technology since its inception in 2013.

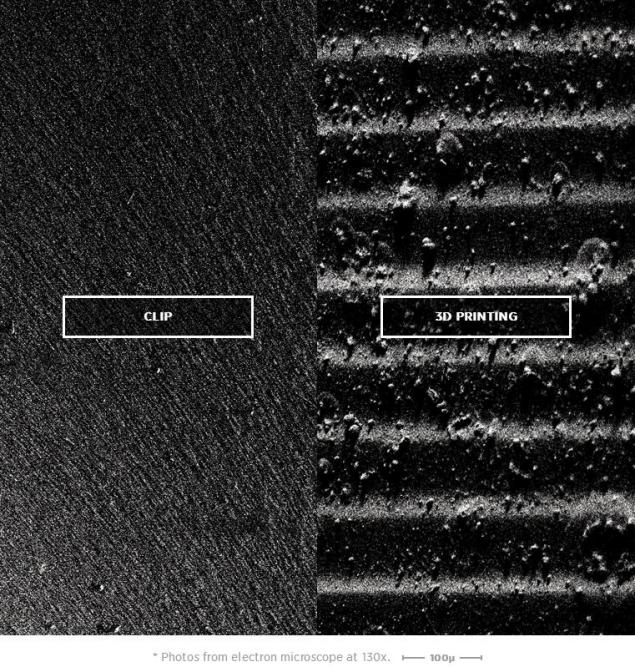

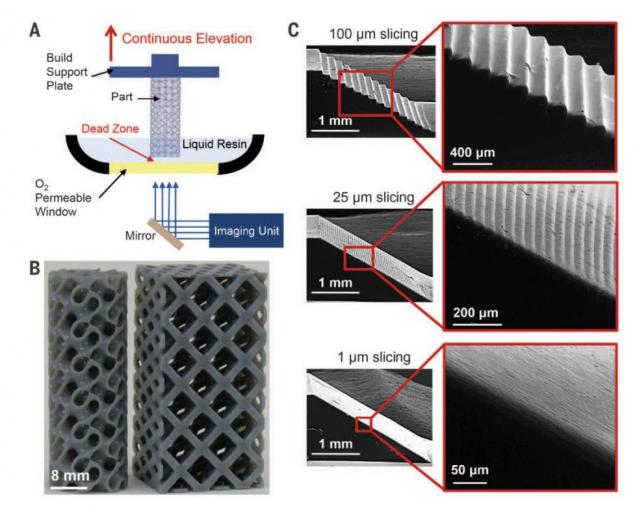

The technology is called Continuous Liquid Interface Productiongo technology (CLIP), the principle of the new method - the use of light and oxygen to cure the photosensitive material (a special type of resin). The method of light exposure on the photosensitive material similar to what we see in the traditional SLA-process. But there are differences, and significant.

There is no layering of work when the plastic is applied to the base layer by layer, until you get the whole object.

Instead, the light radiation used safely for humans and power spectrum for curing the resin. Also, oxygen is used as the inhibitor.

The use of oxygen allows you to manage conducting a photochemical reaction with simultaneous acceleration of the printing process. There is no layered structure of the object being created, the figure turns solid, single. When printing by this method requires special transparent and permeable "windows" through which both light and oxygen. This can be thought of as a large contact lens. The device can control the exact amount of oxygen entering the container with the resin. Thereafter, the oxygen acts as an inhibitor during passage of the photochemical reaction liquid leaving necessary portions of the object. Allows light to harden only those parts of the system, which does not get oxygen.

Thus, oxygen in the system may create a "dead" zone in the tens of microns thick. And just in this zone are not photopolymerization. The device also projects a series of overlapping images using ultraviolet light. This process is similar to playing a movie.

Now Carbon3D already signed a partnership agreement with Sequoia Capital , one of the most respected investment funds. In addition, the investment also provided by Silver Lake Kraftwerk . Total Carbon3D company has already received $ 41 million investment.

The author of the new technology is the current CEO Joseph DeSimone (Joseph DeSimone), and Professor Edward Samulski (Edward Samulski) and Dr. Alex Ermoshkin (Alex Ermoshkin).

Source: geektimes.ru/post/247400/

Magnetic storm tonight reached 9 points, auroras observed up to 52 ° north latitude

New Jersey Governor will decide the fate Tesla in the state