2026

This is Science: 3D optical printing moves to the micro level

Boom of the last 5-7 years - a different kind of 3D printing, be it print necessary items at home , < a href = "http://habrahabr.ru/post/218193/"> print human organs or even entire buildings . But what if you want to print a specific material, and even on the micro scale?

Пьезоэлектрики - A substance capable of generating electric charge and a potential difference in compression or tension. They have long been quietly settled in the home: the piezoelectric lighter nozzle modern printers, and so that we do without the quartz resonator in any digital technology ?!

A group of scientists from the University of California recently published a paper in which proposed a method of three-dimensional printing of polymeric materials with piezoelectric properties using conventional optical 3D-printing. In fact, this method of printing - Development лазерной stereolithography , in which a thin layer of material by laser light cure point by point. However, the main difference is the resolution: up to 1 micron, whereas conventional lithography gives only 0.1 mm or 100 microns.

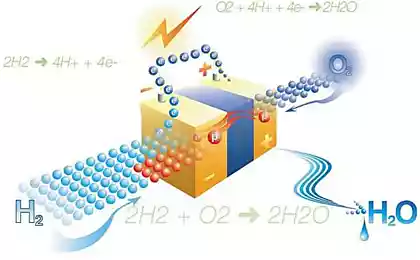

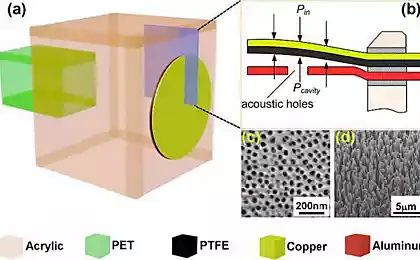

a) Schematic 3D optical microprinting that allows objects to obtain a resolution of a few microns, b) the crystals themselves barium titanate c) scheme prishivki nanocrystals to the matrix i>

Plus, printing is not just polymer and composite materials, which are distributed in the polymer matrix nanocrystals barium titanate (BaTiO 3 < / sub>) - one of the best known piezoelectric materials. When this polymer matrix itself is chemically bonded to the nanocrystals, thus preserving the piezoelectric properties of tensile and compressive strength, in other words, the barium titanate generates an electric charge when changing geometry.

Examples of printed two-dimensional structures i>

Although volumetric barium titanate can generate up to 200 pikoF / N obtained for the composite material 40 pikoF / H are the original record. To better represent yourself digit level, stated in Article 40 pikoF / H corresponds approximately to the potential difference of the order of 600-700 mV when a force is only 10 N, which is not so little.

Examples of printed three-dimensional structures, including complex form i>

In addition, fast and inexpensive printing of the above three-dimensional openwork fibers, quite possibly, would give new impetus to the implementation of smart clothes and produce electricity at its wearing. And finally, the technology can be used when creating a new generation of inkjet printers with a much better resolution by reducing the size of the drops (and similar work is already under way, naprimer ).

Original article in ACSNano (DOI: 10.1021 / nn503268f) i>

Source: habrahabr.ru/post/232853/