1413

A day in the life of Turner borer

Place of my current work, I'll call a "plant." I'll start with the fact that in this factory for three dozen works, my father (a welder). And this factory, I went to him in the team with his brother. Just over a year we have worked in almost complete composition of the family. My brother and I have served as a fitter (each welder has to be a mechanic, my father, there were 3, and the third well, which is Lech Dad worked for many years)

And after I took 2nd place in the competition for the best locksmith plant (1 seat who has not got any! Why? Remained unknown), I was offered to change his profession to Locksmiths 5th grade at Turner borer. And of course I agreed. First of all it's fun, and secondly, the opportunity to develop in a different direction. For nearly two months I have been studying this new profession for me, learning how to say, I'm just working on it.

Let's start in order!

My morning started pretty early, for many it is a shocking figure 5.30am. In summer, it is already full of problems with the sunrise and the awakening does not occur, but the winter is more difficult.

Morning every person begins with a hike of sanitary facilities and describe the remarkable manipulation of personal hygiene I will not. We will not clog the ether is not relevant details =) I can only say that it takes me about 30 minutes.

The remaining 20 minutes before I dedicate breakfast.

And time is 6:20 - it's time to go. Of course, do not forget to kiss his beloved (even sleeping) my wife to check how are things with little son. Well, actually it is in their repertoire: D

I live in the Moscow region in Dolgoprudnyi. My wife and I moved here from Moscow after the wedding. And since our house is 3 km from the train / railway station, then I have three options how to get to it.

1) bus (an option which I never used in 2 years of living in this city) goes through the city and for longer time, if you go on foot

2) Bike (I use this option in the summer and only in good weather)

3) foot (this option and I use it almost always) I think an excellent compensation that do not do exercises in the morning: D 3km walk or run if late

6:45 to Moscow at this time to go work or school is not small people.

I need to drive 2 stations on time minutes 7.

And from the station to the entrance of the plant, too, about 7 minutes walk through the mall.

We pass through the vane pass, and then I meet here are handsome

In the shop I go at 7:00. I rent a pass into the board (where it will be stored until the end of the day). Prior to working time is 30 minutes. During this time I change into a working form, and with his brother and a friend Rides teas.

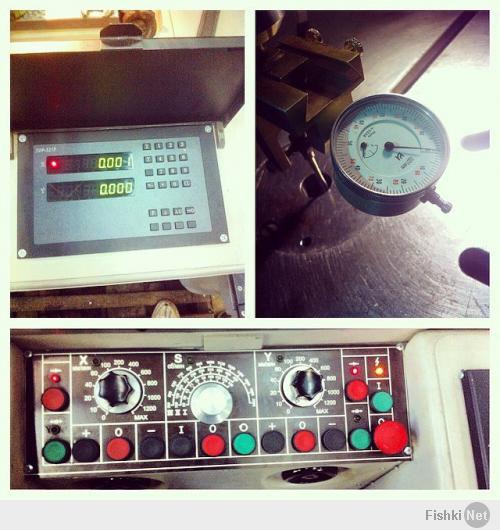

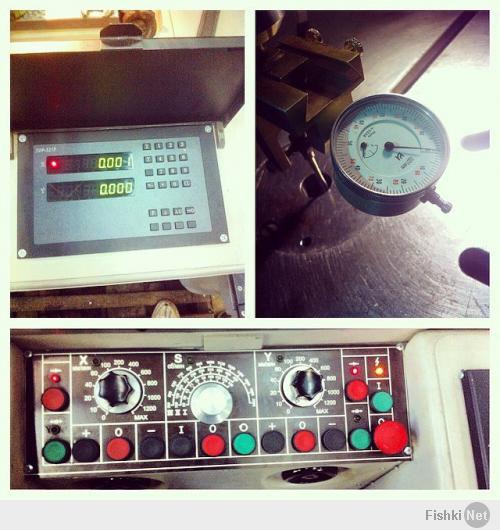

Exactly at 7:30 am I go to turn on your new machine. Well, as a new ... Fired him this year as technology 60s

In fact, work is not complicated: read blueprints, calculate angles, display table on the right size, and ... went

To begin, I'll show you their workplace.

This is one of my magic chests. It stores everything that is often used (for warehousing I still have the boxes)

Open the first drawer and see in it a measuring instrument (micrometers, calipers (claimed second home at the time), indicators tsentroiskateli and fines)

In the second box I lie mainly jacks (varying heights)

The third box reztsov, reamers and cutters

4th key hexagon

In the fifth cone microscope and are most often used

Well, the 6th is a warehouse with drills from small to large

Of course we need to work items such as a large brush for shaving, a small (home-made) brush copper tube and bristle brush with a large, well-bottle with coolant cooling lubricants

Getting Started.

You should always remember safety !!!

Since my item at the time of this post is almost finished, it will have to show that it is possible, but it is quite interesting.

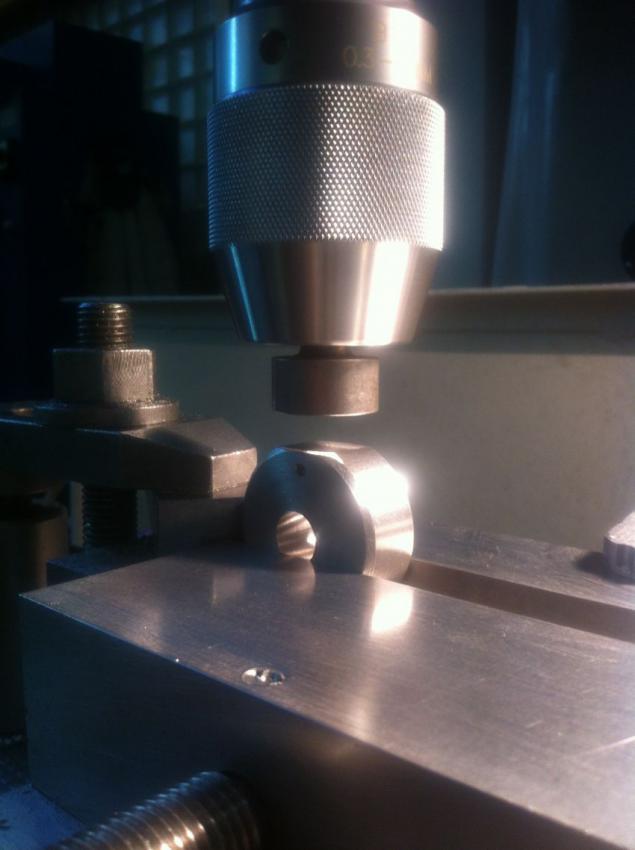

To start the rotating around its axis table we put a vise (approximately in the middle) and clamp them firmly clamps. But as the axis of the surface of the sponge does not correspond to the X-axis table, we need them otparallelit. For this we need tsentroiskatelem cone with a dial indicator.

Put the foot tsentroiskatelya approximately in the center of the sponge. Press it so that the indicator has shown us such 3mm (for this purpose on the display there is a small scale - one bar = 1 mm), and on a large scale put 0.

Next, move the X-axis table you liked any way (eg B +) are looking for a large scale deviation (and do not forget about the small, retains the same 3mm)

If there is a deviation, the rotating table until we reach a value of 0 to 3, and more on small scales. For the accuracy of the X-table pass to the opposite side of the sponge. If 0 is preserved, then a vice otparalleleny relatively secured in an X-axis, so it does not rotate.

(Immediately apologize for the brakes of my video shoot and put the center at the same time extremely comfortable!)

We look at our part. It is cylindrical, but one side has a flat surface (which is necessary to make a hole). The hole should be on this plane 90 ', and then the question arises: How did fix the item so that the plane took exactly horizontal position (after all, it rolled away)?

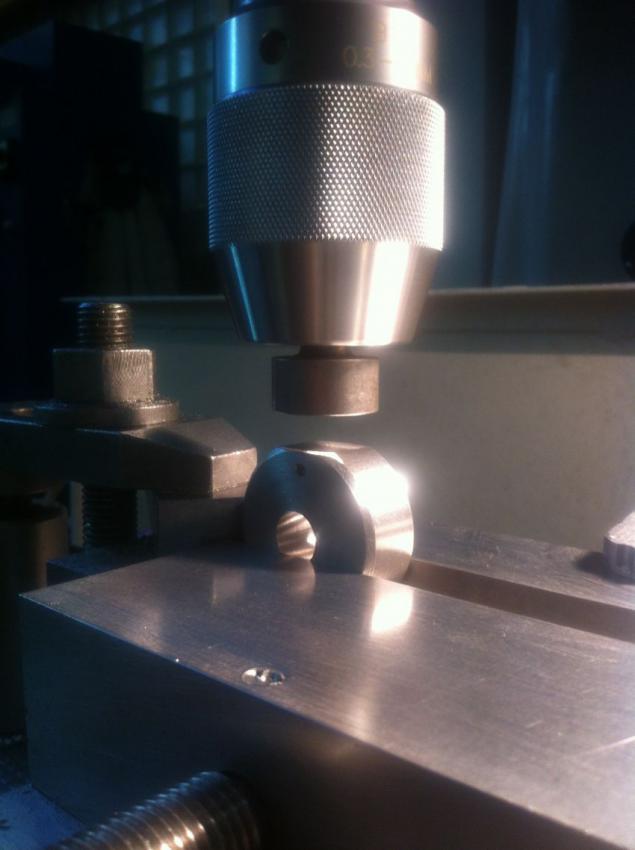

But it is much easier to deal with than it seems. Hold the chuck something flat (in my case, this plug gauge). We lower the spindle and the caliber rests on the plane parts. Actually part is now in the required position, and it is possible to hold a vice.

The figure indicated that the hole exactly in the middle part, we look at the center of the X and Y (again we need tsentroiskatel)

Let's start with Y. In this case, I divide the distance between the jaws exactly in half. The display should be 0 on both jaws. A small scale is left to your discretion, you can use the same 3mm (it does not matter, the main thing that small scale remains unchanged). By the way, each division of a large scale precisely 0, 01mm (weaving)

Center X axis we are looking for exactly the same. The difference is that here it is necessary to lower tsentroiskatel the very detail.

Then be sure (if the item is not alone, and 50 in this case) need to focus on detail to maintain its position on the X axis emphasis we stifle holder, as thoroughly as are the vise. To this whole thing any microns or moved.

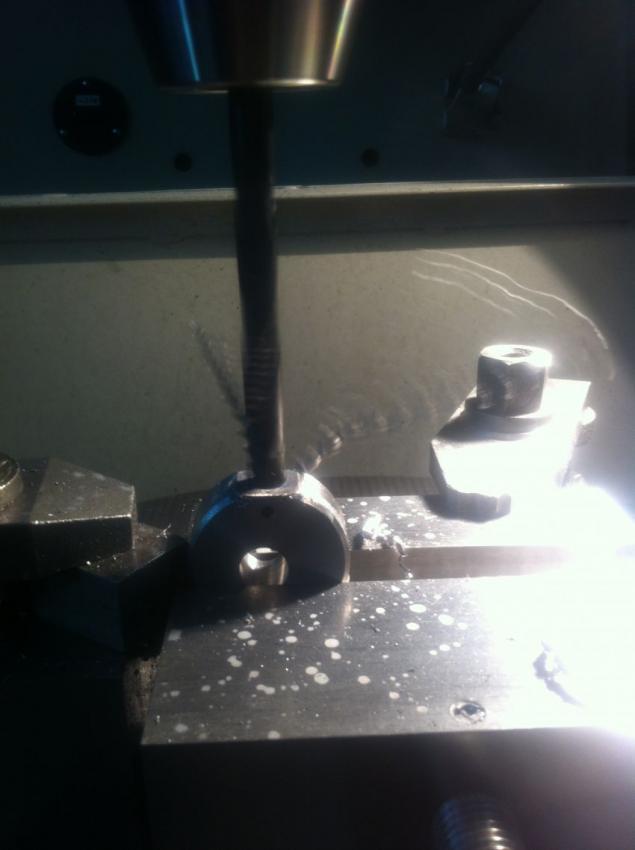

It remains the case for small. First you need to drill a centering a couple of millimeters. This is to ensure that the usual drill is not led astray. This is important, otherwise the hole is not in the center, and this marriage.

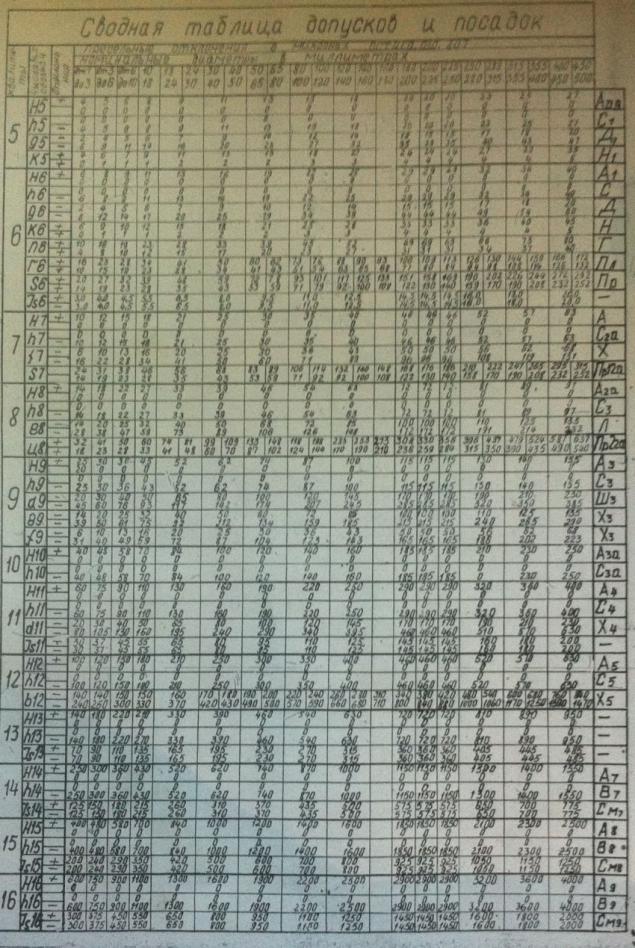

The figure indicated that we need a hole depth of 14 mm and a diameter of 10N7 (10 - mm diameter, H7 - tolerance)

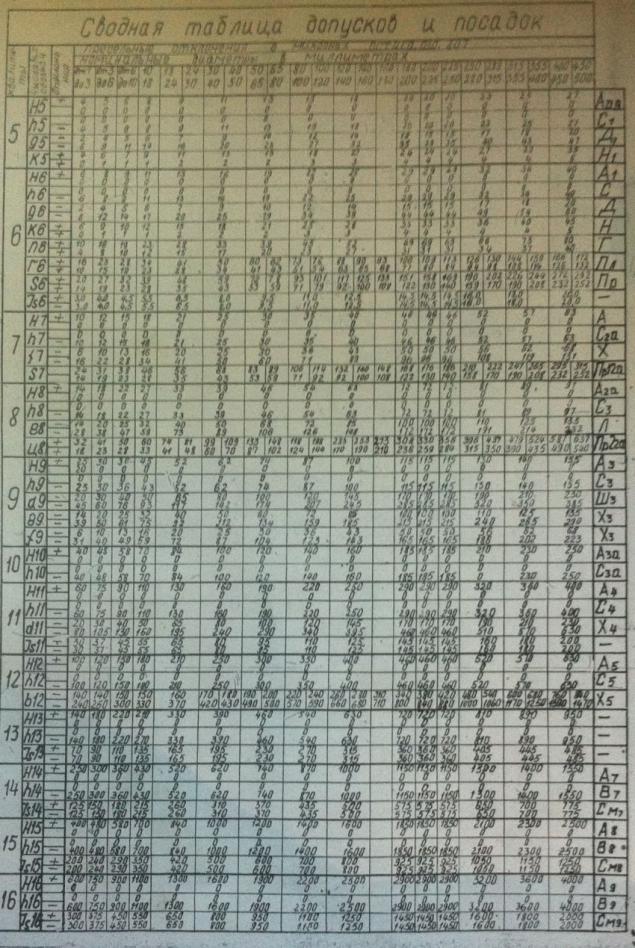

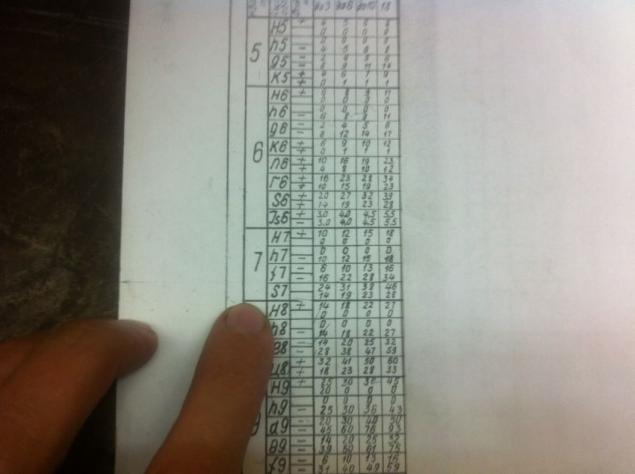

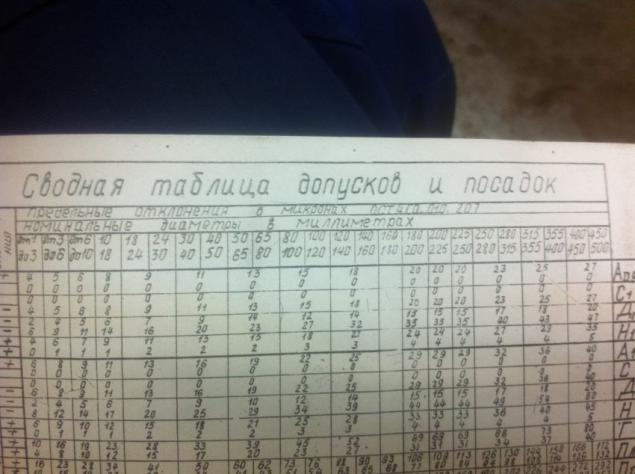

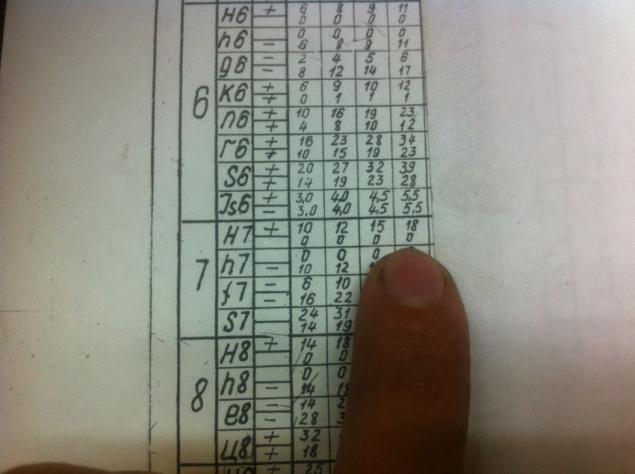

Consider the table of tolerances and fits: at first glance, it is terribly difficult and not foolproof set of numbers, but it's not as scary as it seems.

Consider the example of our hole table:

1) The first thing we know is that our hole diameter 10mm (looking in the table column "Nominal diameters in mm", it is at the top of the table.

We find our diameter. The column of 10 to 18 mm. Everything else we do not need.

2) Next, we know Qualitet 7. Column from the very first class of accuracy in Table

We descend to the desired quality class 7th

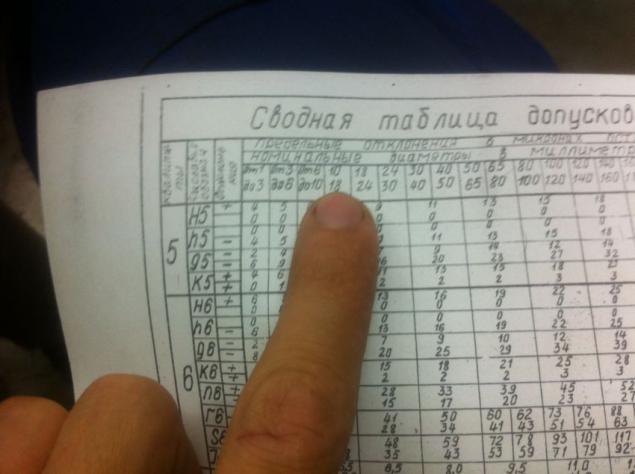

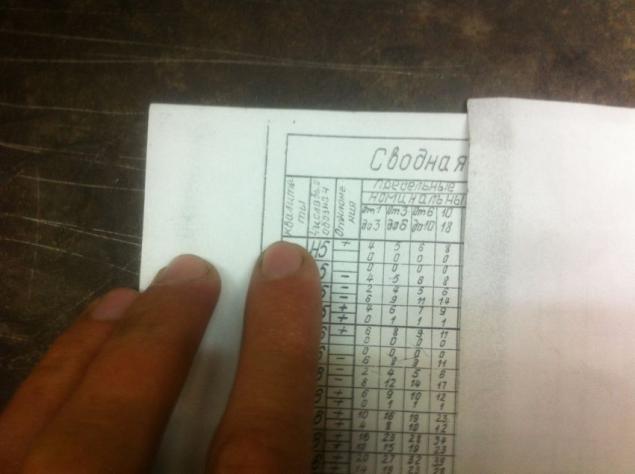

3) We recall that in the drawing before 7 is a capital letter N. corresponds with the diameter of the column and get the table (18, 0) values in microns (1 mm 1mikron is divided by 1000)

--img31--

Now we move away from our parts and a closer look at what kind of numbers we had and what to do with them.

First things first, and in order.

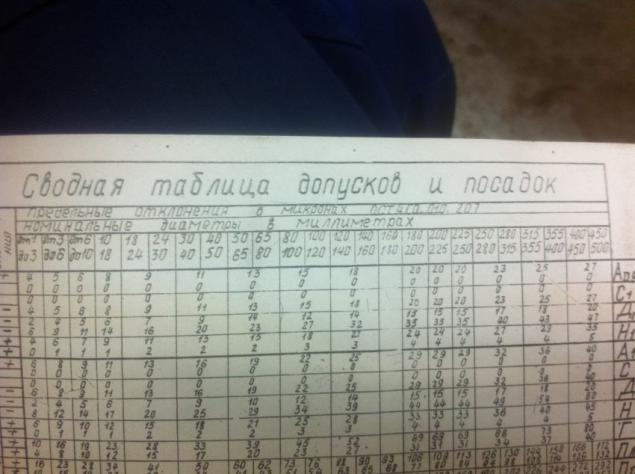

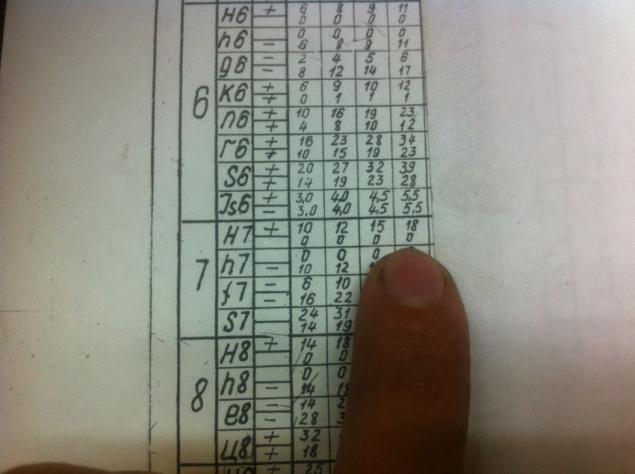

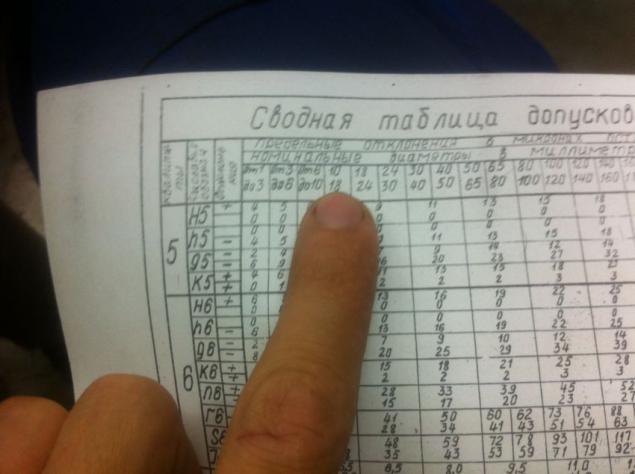

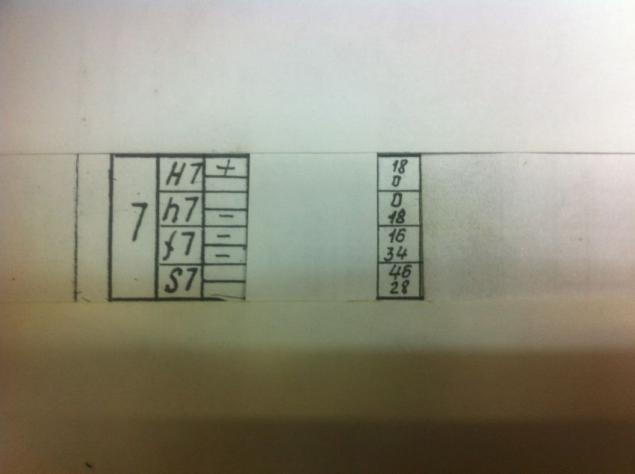

Let's stay on the 7th class of accuracy and diameter of 10mm. (to us that does not distract, I closed we do not need a piece of paper values)

--img32--

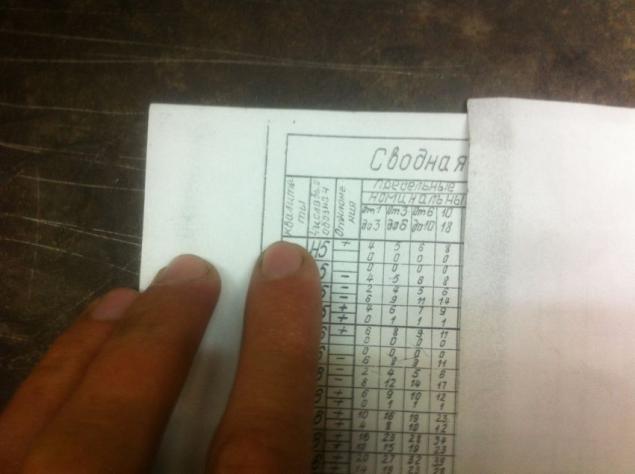

H7 - a capital letter means that we need to make a hole at least 10, 0 mm and not more than 10 018mm. Of course, in this case it is better to be closer to zero, in order to be as far from the incorrigible marriage. But try to reach the average of 10, 009mm

h7 - capital letter here exactly the opposite. It is necessary to keep the value of 9, 982mm to 10, 0 mm, and the mean value of 9, 991mm

f7 - uppercase, you have to be in a minus on the nominal diameter. Admission from 9 to 9 966mm, 984mm. The average value of 9, 975mm

S7 - the title, you have to be in positive territory on the nominal diameter. Admission from 10 to 10 028mm, 046mm. The average value of

10, 037mm, etc. through the entire table.

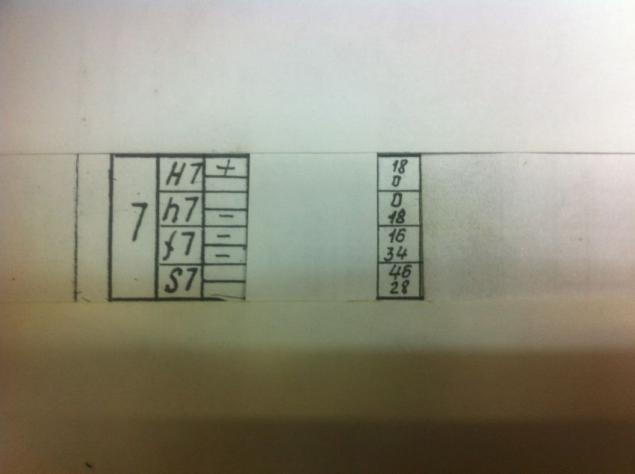

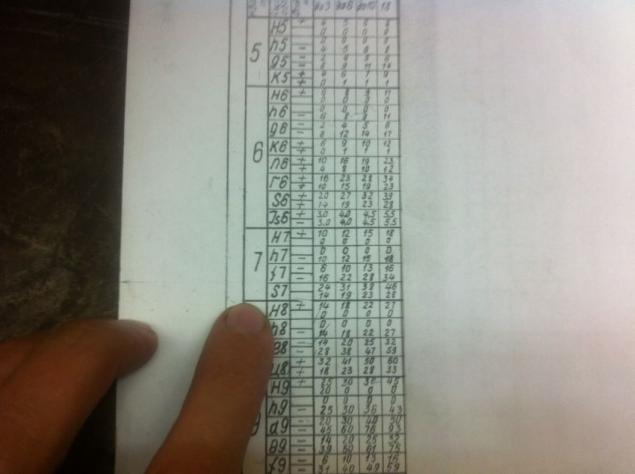

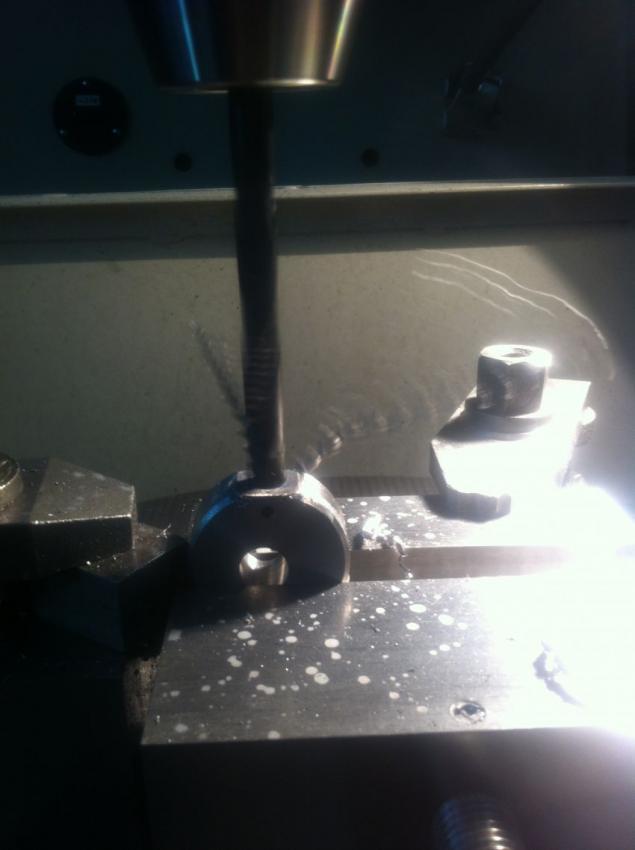

We have an average of 10, 009mm. To do this, we take a drill diameter of 9, 5 drilling at the depth specified in the drawing. And then immediately drill reams 9, 9.

--img33--

And after I took 2nd place in the competition for the best locksmith plant (1 seat who has not got any! Why? Remained unknown), I was offered to change his profession to Locksmiths 5th grade at Turner borer. And of course I agreed. First of all it's fun, and secondly, the opportunity to develop in a different direction. For nearly two months I have been studying this new profession for me, learning how to say, I'm just working on it.

Let's start in order!

My morning started pretty early, for many it is a shocking figure 5.30am. In summer, it is already full of problems with the sunrise and the awakening does not occur, but the winter is more difficult.

Morning every person begins with a hike of sanitary facilities and describe the remarkable manipulation of personal hygiene I will not. We will not clog the ether is not relevant details =) I can only say that it takes me about 30 minutes.

The remaining 20 minutes before I dedicate breakfast.

And time is 6:20 - it's time to go. Of course, do not forget to kiss his beloved (even sleeping) my wife to check how are things with little son. Well, actually it is in their repertoire: D

I live in the Moscow region in Dolgoprudnyi. My wife and I moved here from Moscow after the wedding. And since our house is 3 km from the train / railway station, then I have three options how to get to it.

1) bus (an option which I never used in 2 years of living in this city) goes through the city and for longer time, if you go on foot

2) Bike (I use this option in the summer and only in good weather)

3) foot (this option and I use it almost always) I think an excellent compensation that do not do exercises in the morning: D 3km walk or run if late

6:45 to Moscow at this time to go work or school is not small people.

I need to drive 2 stations on time minutes 7.

And from the station to the entrance of the plant, too, about 7 minutes walk through the mall.

We pass through the vane pass, and then I meet here are handsome

In the shop I go at 7:00. I rent a pass into the board (where it will be stored until the end of the day). Prior to working time is 30 minutes. During this time I change into a working form, and with his brother and a friend Rides teas.

Exactly at 7:30 am I go to turn on your new machine. Well, as a new ... Fired him this year as technology 60s

In fact, work is not complicated: read blueprints, calculate angles, display table on the right size, and ... went

To begin, I'll show you their workplace.

This is one of my magic chests. It stores everything that is often used (for warehousing I still have the boxes)

Open the first drawer and see in it a measuring instrument (micrometers, calipers (claimed second home at the time), indicators tsentroiskateli and fines)

In the second box I lie mainly jacks (varying heights)

The third box reztsov, reamers and cutters

4th key hexagon

In the fifth cone microscope and are most often used

Well, the 6th is a warehouse with drills from small to large

Of course we need to work items such as a large brush for shaving, a small (home-made) brush copper tube and bristle brush with a large, well-bottle with coolant cooling lubricants

Getting Started.

You should always remember safety !!!

Since my item at the time of this post is almost finished, it will have to show that it is possible, but it is quite interesting.

To start the rotating around its axis table we put a vise (approximately in the middle) and clamp them firmly clamps. But as the axis of the surface of the sponge does not correspond to the X-axis table, we need them otparallelit. For this we need tsentroiskatelem cone with a dial indicator.

Put the foot tsentroiskatelya approximately in the center of the sponge. Press it so that the indicator has shown us such 3mm (for this purpose on the display there is a small scale - one bar = 1 mm), and on a large scale put 0.

Next, move the X-axis table you liked any way (eg B +) are looking for a large scale deviation (and do not forget about the small, retains the same 3mm)

If there is a deviation, the rotating table until we reach a value of 0 to 3, and more on small scales. For the accuracy of the X-table pass to the opposite side of the sponge. If 0 is preserved, then a vice otparalleleny relatively secured in an X-axis, so it does not rotate.

(Immediately apologize for the brakes of my video shoot and put the center at the same time extremely comfortable!)

We look at our part. It is cylindrical, but one side has a flat surface (which is necessary to make a hole). The hole should be on this plane 90 ', and then the question arises: How did fix the item so that the plane took exactly horizontal position (after all, it rolled away)?

But it is much easier to deal with than it seems. Hold the chuck something flat (in my case, this plug gauge). We lower the spindle and the caliber rests on the plane parts. Actually part is now in the required position, and it is possible to hold a vice.

The figure indicated that the hole exactly in the middle part, we look at the center of the X and Y (again we need tsentroiskatel)

Let's start with Y. In this case, I divide the distance between the jaws exactly in half. The display should be 0 on both jaws. A small scale is left to your discretion, you can use the same 3mm (it does not matter, the main thing that small scale remains unchanged). By the way, each division of a large scale precisely 0, 01mm (weaving)

Center X axis we are looking for exactly the same. The difference is that here it is necessary to lower tsentroiskatel the very detail.

Then be sure (if the item is not alone, and 50 in this case) need to focus on detail to maintain its position on the X axis emphasis we stifle holder, as thoroughly as are the vise. To this whole thing any microns or moved.

It remains the case for small. First you need to drill a centering a couple of millimeters. This is to ensure that the usual drill is not led astray. This is important, otherwise the hole is not in the center, and this marriage.

The figure indicated that we need a hole depth of 14 mm and a diameter of 10N7 (10 - mm diameter, H7 - tolerance)

Consider the table of tolerances and fits: at first glance, it is terribly difficult and not foolproof set of numbers, but it's not as scary as it seems.

Consider the example of our hole table:

1) The first thing we know is that our hole diameter 10mm (looking in the table column "Nominal diameters in mm", it is at the top of the table.

We find our diameter. The column of 10 to 18 mm. Everything else we do not need.

2) Next, we know Qualitet 7. Column from the very first class of accuracy in Table

We descend to the desired quality class 7th

3) We recall that in the drawing before 7 is a capital letter N. corresponds with the diameter of the column and get the table (18, 0) values in microns (1 mm 1mikron is divided by 1000)

--img31--

Now we move away from our parts and a closer look at what kind of numbers we had and what to do with them.

First things first, and in order.

Let's stay on the 7th class of accuracy and diameter of 10mm. (to us that does not distract, I closed we do not need a piece of paper values)

--img32--

H7 - a capital letter means that we need to make a hole at least 10, 0 mm and not more than 10 018mm. Of course, in this case it is better to be closer to zero, in order to be as far from the incorrigible marriage. But try to reach the average of 10, 009mm

h7 - capital letter here exactly the opposite. It is necessary to keep the value of 9, 982mm to 10, 0 mm, and the mean value of 9, 991mm

f7 - uppercase, you have to be in a minus on the nominal diameter. Admission from 9 to 9 966mm, 984mm. The average value of 9, 975mm

S7 - the title, you have to be in positive territory on the nominal diameter. Admission from 10 to 10 028mm, 046mm. The average value of

10, 037mm, etc. through the entire table.

We have an average of 10, 009mm. To do this, we take a drill diameter of 9, 5 drilling at the depth specified in the drawing. And then immediately drill reams 9, 9.

--img33--