1254

Global losses from friction in buses and trucks - fascinating figures

Recently, several leading experts in the field of tribology published a report entitled « Global energy consumption due to friction in trucks and buses », which loosely translated sounds like" Global energy losses due to friction in buses and trucks. " Highlights:

- In 2012, the operation of the world's fleet of trucks and buses, 180 000 million liters of fuel consumed just to overcome friction forces.

- «New tribology" could save 105,000 million euros and 75 000 million liters of fuel annually, is expected to reduce emissions of CO 2 sub> at 200 million tons.

The report analyzed the losses due to friction in the engine, transmission, tires, brakes and accessories. The authors studied the four main categories of vehicles (hereinafter TC): single trucks, various combinations of tractor-trailers, buses and coaches. Friction losses were analyzed on the basis of previously published data. Friction coefficients were estimated for the following cases:

- Average statistical modern TS;

- TC, built using the best commercial technologies currently available;

- TC, which uses the most advanced technology known today;

- Vehicle that can be constructed with the use of new technologies that will be created in the next 12 years.

The last point, in some extent, is the result of imagination, but on the authority of the authors, it can be used as an assessment of the likely immediate future. (Approx. Mine).

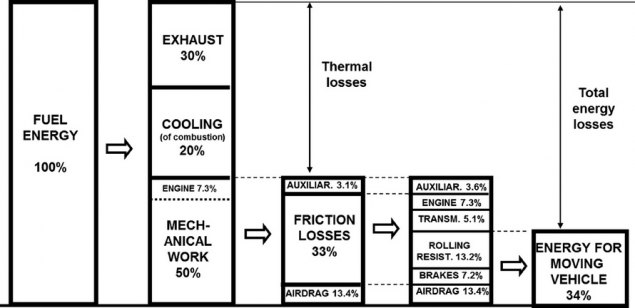

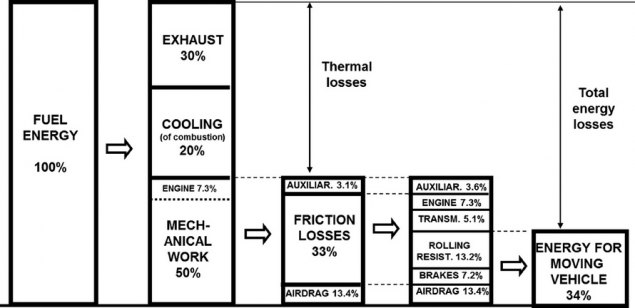

Scheme of the main energy losses is as follows:

As we can see, 33% of the fuel used to overcome friction in the engine, transmission and tires. Thus on the actual movement of the car takes only 34% percent of the fuel, the rest just heats the atmosphere. Electrification of the city buses are not only beneficial in terms of improving efficiency, but also reduce and indirect losses for light friction - estimated such losses in electric TC is approximately half compared to similar diesel.

But even if you do not convert all the buses to electric right now, reducing friction in the mechanism will save huge amounts of fuel. Implementation of already known and the development of new mechanisms for reducing friction, the evaluation can reduce friction loss by 14% in the short term (4 to 8 years) and 37% - in the long term (8 to 12 years). At the moment, we are talking about the following areas:

- A further improvement of lubricating oils (extensive way).

- Develop and implement coatings with low friction (diamond-like films, multilayer coatings, graphite, and etc.). < Modification of the rubbing surfaces (metal texturing, optimization of tires to reduce rolling friction).

______________________

Text prepared in blog editor from © SoftCoder.ru h6>

Source: habrahabr.ru/post/223573/