983

Interesting facts about the little details

The benefits of the invention, the screw thread is as obvious as the benefits from the opening of the wheel man. This is probably one of the simplest mechanisms, without which the development of science and technology would be simply impossible. Many of the things created by man, were made with the help of this simple and brilliant invention.

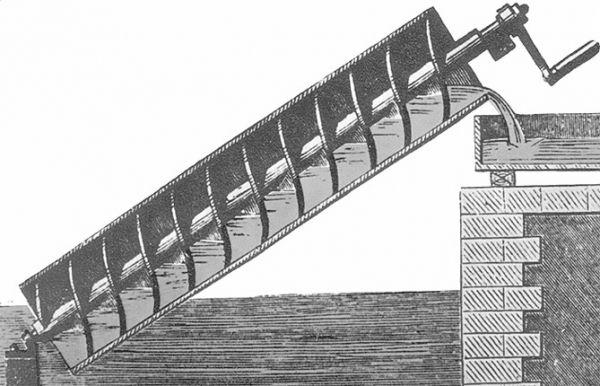

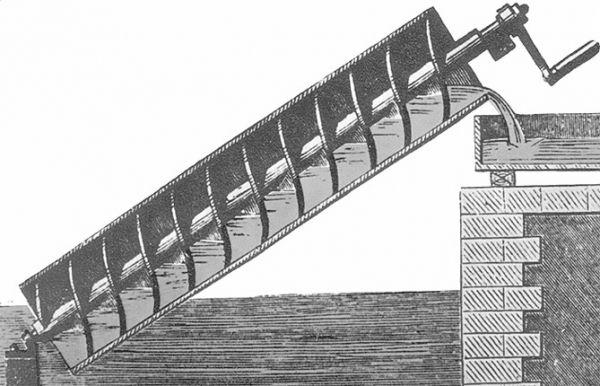

Spiral screw geometry is unique. It sounds strange, but subject to a form in itself is a multifunctional device. Such a geometry can be used to secure the individual design elements, rotating helical item can be used for transmission or clutch as a transport conveyor. The latter option is the use of screw geometry is better known as the Archimedes screw. Generally, the legendary ancient Greek genius credited with many discoveries, and probably not all of them belong to him. Not assert that this great scientist discovered a helical shape, but one of the first mentions of the practical application of such a spiral is associated with ancient Greece (third century BC).

The so-called Archimedes screw - a device that in the past, people used to transfer water from a distance. Screw axis to rotate in the gutter and the water gradually to the desired direction. According to one version, Archimedes invented a device during the time of his studies in Alexandria, where the practice was able to apply their knowledge for draining flooded Nile lands.

Whoever invented the first screw, it probably spied on its shape in nature. Maybe people saw the ivy chokes the tree in a spiral, and maybe he was inspired by the twisted shape of a seashell.

Geometry, born of nature, it is often so accurate and complete that the person refuses to believe in its natural origin. This is a relatively recent example. Fans carry out excavations from time to time are sensational finds. In 1998, an expedition of the Center "MAI - Kosmopoisk" explored the area in the south of the Kaluga region in search of meteorites. In place of the search for one of the participants of the expedition he discovered a strange stone, which could see the petrified bolt.

Scholars immediately raised a stir - where he's come from? Taking into account the time limits which are necessary to convert the object into the stone, we can conclude that the age of discovery has to be hundreds of millions of years. But if so, who made this piece? Are 300 million years ago on the Earth there was an advanced civilization, which could make the complex mechanisms? The explanation was really very simple.

After some disputes experts nevertheless recognized the fossil, it turned out to be a creature called crinoids (lat. Crinoidea), or sea lily.

The specific structure of these animals has misled researchers who long refused to believe that the "bolt" created by nature. Interestingly, this incident with a screw in stone - is not unique. Sea lilies are often mistaken for the artifacts of ancient civilization - that they will call them the remains of extraterrestrial machines, you will see the country's "hoses" message from the future.

But in reality, everything is much simpler and more boring. The entire length of the body of these creatures (crinoids) ran the esophagus, which often was scored on plankton and sand. Under the influence of the contents of the esophagus time to stone, to form the probe, which is so similar to a man-made object.

The most common form of two slots - direct and cross. Although invented and patented cross-shaped slits John Thompson (John Thompson), a screw head (and a screwdriver to work with it) called Phillips (the Dutch brand has nothing to do), in honor of Henry F. Phillips (Henry F. Phillips ), an American businessman from Portland, Oregon, which bought the patent and Thompson was able to "roll out" the dignity of the new screws.

The advantage of a cruciform shaped slot lie in a more secure grip of the screw and screwdriver, which was especially important in manufacturing, particularly in the assembly of the vehicle. In the thirties of the last century, the famous car manufacturers (eg, General Motors) to quickly appreciated the convenience and efficiency of the new screws and took them into service.

The interior of the 1939 Cadillac is not difficult to notice the cap Phillips

Years passed, and the shape of the slot was still standard - or straight or Phillips. But as you know, there is no limit to perfection. Over time, even the usual screw cap appeared improved.

In fact, the screw refers to a category of things that are extremely difficult to somehow improve and do better. Helical shape itself is ideal, and to come up with something more sophisticated, you have to be a real talent of the inventor. Nevertheless, sometimes there are people who shoulder the tasks of any complexity. These enthusiasts can easily re-discover or invent a bicycle cog in a new way.

The main drawback of, or would be correct to say inconvenience that carries a screw - lock to standard slot. Each screw has a slot defined shape and size. All this leads to the need for a tool to determine the standard. In the arsenal of any self-respecting wizard necessarily have a set of screwdrivers, with which it can tighten and loosen the parts of different sizes. By and large, it is very impractical and inconvenient, especially when it comes to industrial scale. And yet, the problem is very simple, and found it to American inventors and founders Outlaw Fasteners from Charlotte, North Carolina.

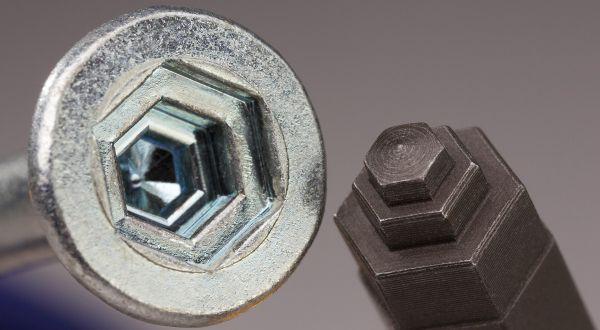

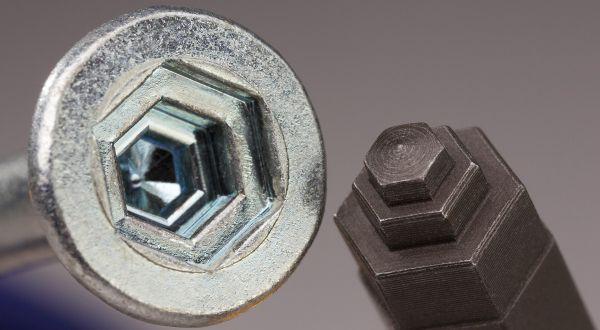

The design team has patented a new universal slot, which is practically devoid of such shortcomings. It has the shape of a stepped pyramid with a recessed hexagonal base. According to the creators of the revolutionary screw, a strange form of slot carries a lot of advantages. Firstly, there is no need to look for a screwdriver size. Secondly, the adhesive force on a form slot is much higher, and therefore bits do not tear thread. In addition, a special system of fixing screws to prevent unwanted oscillations and the deviation in the tightening of the screw.

The project was announced on the popular Kickstarter and collected the necessary sum for the promotion of "universal standard" - more than a hundred thousand dollars. The only pity is that the innovative idea not solve the problem with Mount screwdrivers old standards, which still have to keep on hand, even if the new slot accustomed.

In any job, even the most boring, there is room for a smile, you just need to creatively approach to the process.

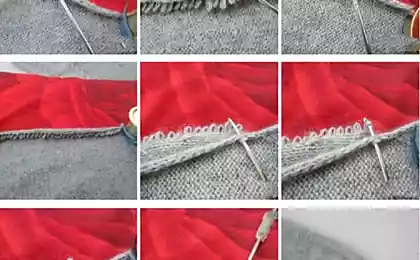

Japanese designer Cano Yuma (Yuma Kano) figured out a way to diversify is simple and monotonous activity as tightening the screws with a screwdriver. His proposal is surprisingly simple, but yet very unusual. Cano Hume proposes to change the shape of the cap is twisted details. Generally, the shape of the part is made according to the standards, ensuring the best grip and maximum efficiency when used on an industrial scale. However, according to the Japanese designer, sometimes you can fall back on the rules and to make an unexpected move - to abandon the usual form of straight or cross-shaped slot. This project is implemented in cooperation with the designer Komuro Seisakusho, plant for the production of screws in East Osaka.

At the moment, there are a large number of standards of the metal piece. There is a classical direct slot, there is a slot in the form of stars, there is a cross-shaped slot, a polygon, etc. A Japanese designer offers its own slot, simple and clear to everyone - in the form of a smiley face.

Of course, to work with such a screw is not suitable for either a screwdriver or bit - they must have an appropriate projection. Usually tool such detail or to screw or unscrew. However, by and large, what does it matter if a tiny cog cheer up, even just a little bit? Besides the unique parts can carry and practical benefits: for example, it can protect the structure from "skillful hands" or simply to emphasize the originality of the assembly.

In principle, the idea is not new Japanese just before nobody paid much attention to a custom slot. Some manufacturers deliberately use the special "secret" form of slot titled Clutch head. This head has ground off the edge, so you can only work with a screwdriver clockwise.

For example, to analyze some models of the line filter APC, will have to break the case, since there is also made an inclined slot. This item can only twist and unscrew the usual way will fail.

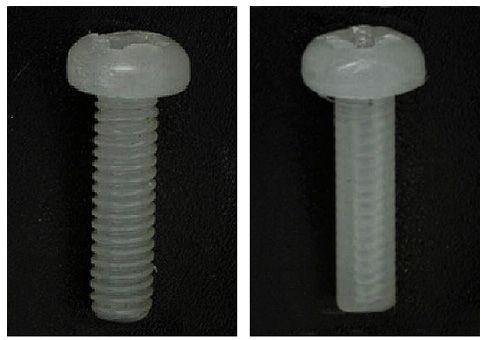

The screw - a very simple and reliable fastening element. However, it can be "broken". His slot can be broken by excessive force applied in the process of loosening, and the thread itself may be disrupted. Giving forecasts - a thankless task, but still there is hope that in the future these problems will be much less. In 2002, Japanese scientists company Mitsubishi Heavy Industries have demonstrated "improved" version of the screw. They used it to create a polymer material with a memory effect.

In the normal state, this member has a classical geometry with a screw thread. But it is worth it to heat up and spiral notch disappears - screw straightens up, turning into a rod that you can easily pull out of the slot. The cost of this element higher than conventional steel screws - probably for this reason that the "eternal" screw is not widespread. However, the invention of Japanese engineers gives an idea of what awaits us in the future.

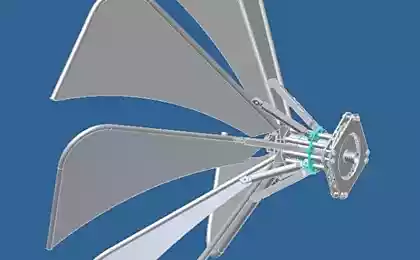

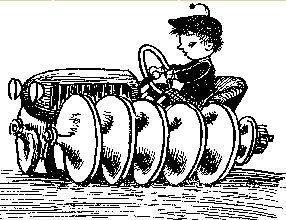

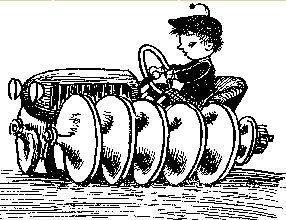

If you look at the rotating thread such as a drill, there will be an optical illusion - the subject of "alive" and the impression that the helical notch moves. Perhaps this illusion and suggested a wonderful man mechanism alternative to the wheel - Screw Rotary mover. This Moving transport element got its name from the German word Schnecke, which translates as "snail". Use as a rotating helical element move rods allowed the inventors to design a new type of all-terrain vehicles.

Actually, all-terrain vehicles called rotary snow machines would not be entirely correct, because such vehicles are not able to move on any ground. For example, in a conventional asphalt or concrete road shnekohod not show its advantages - it will be sluggish and slow. But is such a machine to be on marshy or snowy terrain, and it is easy to take place where other vehicles are hopelessly bogged down.

Even today, construction shnekohoda surprising for those who have not seen this class of machine, it was too strange looks such devices.

But history shnekohodov begins much earlier than you might expect. For example, in the USSR, the engineers were well aware of the potential of this type of machinery. Their production has not been established in large numbers, but some copies were in service in the Soviet army. For the same reason, the national press has focused on the unusual design of all-terrain vehicles. But the mention of them we find a completely unusual place. In 1958, in the journal "Youth" was first published children's book Nikolai Nosov "Dunno in the Sun City", where the author describes the surprisingly accurate rotary snow machines, calling them "spiralehodami».

Curiously, the first national cross-country vehicles with screws were developed only a decade after the release of this book. They were engaged ZIL engineers under the leadership of the Soviet designer Vitaly A. Grachev.

Henry Ford, owner of the legendary Ford Motor Company, was one of the first who thought about the mass production of machines with rotary snow gear. At the beginning of last century, he sought to expand production and began to experiment with different types of tractors. Shareholders of the company, which owned 41 shares of 5 percent, Ford strongly hindered in its "creative research". Therefore, to continue the search for a new, jointly with his son Henry had to create a separate company Henry Ford and Son, which later began to use the brand "Fordsan» (Fordson). One of the conceptual fordsanov (or Fordson - so called in the Soviet version of the tractors manufactured in the late twenties of the XX century under license) had an unusual propulsion - a pair of rotating spiral cylinders. The model was named Armstead Snow Motor, or "snow devil».

Chronicle of 1929 very clearly shows the benefits of shnekohoda on snow-covered terrain. The video shows a working model of the tractor absolutely fordsana that can easily take place where the horse is hopelessly mired in the snowdrifts.

And after all, who first invented shnekohod? Perhaps it was the Swiss Iakob Morath, who in 1899 patented a machine in the United States with a screw drive for doing farm work. Conceived as it was earlier (according to some sources - in 1868). Russia has also been patented model sledge, who used the same principle as its author was F. Dergint.

Claus Philipp Maria Schenk Graf von Stauffenberg went down in history primarily because his name figured in the list of indicted war Wehrmacht, convicted on the conspiracy against Hitler. But this man's life there is still one thing that is of direct relevance to our topic.

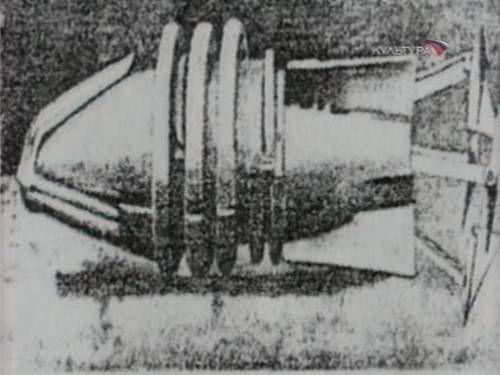

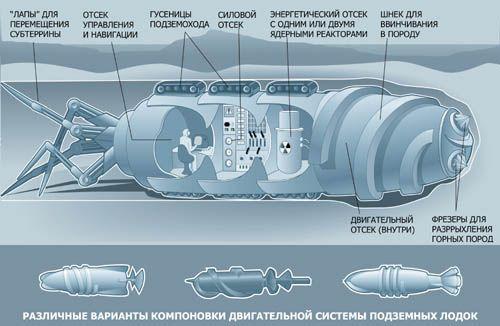

It is no secret that the German High Command has stimulated a number of projects to create new weapons and equipment for the German army. Claus von Stauffenberg led one such secret research. Under his boat it was designed to move underground. Yes, you heard right - just below the ground. Actually, that's strange? Rigs that make tunnels have long been known. The question was how to make a mobile unit. At the heart of this amazing invention of the project lay a German engineer Wilhelm von Verna, who patented it in 1933. Such a boat was crowned with a huge powerful drill, which allows the vehicle to literally bump into solid rock.

When the funds were allocated for the project, it was assumed that these boats will have time to make ground for the invasion of Britain, guiding them under the English Channel. According to calculations by the German engineers, the ship could move a team of five people and carry 300 kg warhead in, moving under the ground at a speed of 7 km / h. But as you know, "Operation Sea Lion" did not take place, and Hitler himself considered it more prudent to bet on Air Force. Ultimately, the development of the German underground boat was frozen.

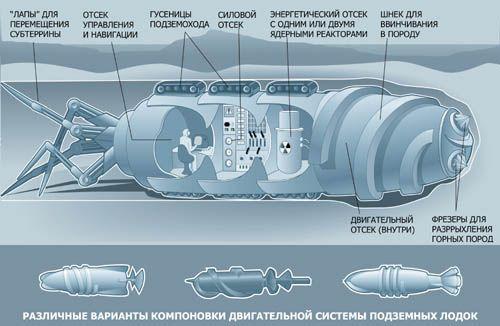

After the war, the Soviet Union, such studies were conducted on developments Shal'nikov Trebeleva. Our compatriot long and detailed studied similar projects overseas colleagues and tried to systematize information about podzemohodah. As a result, Soviet scientists concluded that the best way to create an underground boat - to try to find an alternative to the usual snap mechanism that was used in the construction of almost all underground boat at the time.

To move away from the stereotype of an underground boat, scientists began to look closely to ordinary moles. Animal experiments were carried out quite a few, in which scientists were observing and trying to understand how the moles so quickly makes its way underground. It turned out that in the process of digging tunnels the mole involves not only the front paws, but the whole body. Head and front paws, he performs the rotation and forward movement, and the hind legs pushed off the ground.

A similar principle has been implemented and in the car Trebeleva, where instead of the hind legs used jacks. Together with the designers and Baskin A. Kirillov Trebelev I could make a machine that worked with an efficiency of 300 revolutions per minute, giving the potential for promotion to 10 meters per hour. And that was just the beginning. Later, in the Soviet Union it was designed and built a real underground cruiser, codenamed "Combat mole».

This machine is brilliantly passed the first test, but on the second attempt to test the functionality of the device, in the Ural Mountains, there was an explosion, which killed the entire crew of underground vessel. This promising development has been suspended.

That screw - a piece for fixing structural elements, it is obvious to all. But as you can see, the scope of this megapoleznoy tiny things much broader.

--img26--

Spiral screw geometry is unique. It sounds strange, but subject to a form in itself is a multifunctional device. Such a geometry can be used to secure the individual design elements, rotating helical item can be used for transmission or clutch as a transport conveyor. The latter option is the use of screw geometry is better known as the Archimedes screw. Generally, the legendary ancient Greek genius credited with many discoveries, and probably not all of them belong to him. Not assert that this great scientist discovered a helical shape, but one of the first mentions of the practical application of such a spiral is associated with ancient Greece (third century BC).

The so-called Archimedes screw - a device that in the past, people used to transfer water from a distance. Screw axis to rotate in the gutter and the water gradually to the desired direction. According to one version, Archimedes invented a device during the time of his studies in Alexandria, where the practice was able to apply their knowledge for draining flooded Nile lands.

Whoever invented the first screw, it probably spied on its shape in nature. Maybe people saw the ivy chokes the tree in a spiral, and maybe he was inspired by the twisted shape of a seashell.

Geometry, born of nature, it is often so accurate and complete that the person refuses to believe in its natural origin. This is a relatively recent example. Fans carry out excavations from time to time are sensational finds. In 1998, an expedition of the Center "MAI - Kosmopoisk" explored the area in the south of the Kaluga region in search of meteorites. In place of the search for one of the participants of the expedition he discovered a strange stone, which could see the petrified bolt.

Scholars immediately raised a stir - where he's come from? Taking into account the time limits which are necessary to convert the object into the stone, we can conclude that the age of discovery has to be hundreds of millions of years. But if so, who made this piece? Are 300 million years ago on the Earth there was an advanced civilization, which could make the complex mechanisms? The explanation was really very simple.

After some disputes experts nevertheless recognized the fossil, it turned out to be a creature called crinoids (lat. Crinoidea), or sea lily.

The specific structure of these animals has misled researchers who long refused to believe that the "bolt" created by nature. Interestingly, this incident with a screw in stone - is not unique. Sea lilies are often mistaken for the artifacts of ancient civilization - that they will call them the remains of extraterrestrial machines, you will see the country's "hoses" message from the future.

But in reality, everything is much simpler and more boring. The entire length of the body of these creatures (crinoids) ran the esophagus, which often was scored on plankton and sand. Under the influence of the contents of the esophagus time to stone, to form the probe, which is so similar to a man-made object.

The most common form of two slots - direct and cross. Although invented and patented cross-shaped slits John Thompson (John Thompson), a screw head (and a screwdriver to work with it) called Phillips (the Dutch brand has nothing to do), in honor of Henry F. Phillips (Henry F. Phillips ), an American businessman from Portland, Oregon, which bought the patent and Thompson was able to "roll out" the dignity of the new screws.

The advantage of a cruciform shaped slot lie in a more secure grip of the screw and screwdriver, which was especially important in manufacturing, particularly in the assembly of the vehicle. In the thirties of the last century, the famous car manufacturers (eg, General Motors) to quickly appreciated the convenience and efficiency of the new screws and took them into service.

The interior of the 1939 Cadillac is not difficult to notice the cap Phillips

Years passed, and the shape of the slot was still standard - or straight or Phillips. But as you know, there is no limit to perfection. Over time, even the usual screw cap appeared improved.

In fact, the screw refers to a category of things that are extremely difficult to somehow improve and do better. Helical shape itself is ideal, and to come up with something more sophisticated, you have to be a real talent of the inventor. Nevertheless, sometimes there are people who shoulder the tasks of any complexity. These enthusiasts can easily re-discover or invent a bicycle cog in a new way.

The main drawback of, or would be correct to say inconvenience that carries a screw - lock to standard slot. Each screw has a slot defined shape and size. All this leads to the need for a tool to determine the standard. In the arsenal of any self-respecting wizard necessarily have a set of screwdrivers, with which it can tighten and loosen the parts of different sizes. By and large, it is very impractical and inconvenient, especially when it comes to industrial scale. And yet, the problem is very simple, and found it to American inventors and founders Outlaw Fasteners from Charlotte, North Carolina.

The design team has patented a new universal slot, which is practically devoid of such shortcomings. It has the shape of a stepped pyramid with a recessed hexagonal base. According to the creators of the revolutionary screw, a strange form of slot carries a lot of advantages. Firstly, there is no need to look for a screwdriver size. Secondly, the adhesive force on a form slot is much higher, and therefore bits do not tear thread. In addition, a special system of fixing screws to prevent unwanted oscillations and the deviation in the tightening of the screw.

The project was announced on the popular Kickstarter and collected the necessary sum for the promotion of "universal standard" - more than a hundred thousand dollars. The only pity is that the innovative idea not solve the problem with Mount screwdrivers old standards, which still have to keep on hand, even if the new slot accustomed.

In any job, even the most boring, there is room for a smile, you just need to creatively approach to the process.

Japanese designer Cano Yuma (Yuma Kano) figured out a way to diversify is simple and monotonous activity as tightening the screws with a screwdriver. His proposal is surprisingly simple, but yet very unusual. Cano Hume proposes to change the shape of the cap is twisted details. Generally, the shape of the part is made according to the standards, ensuring the best grip and maximum efficiency when used on an industrial scale. However, according to the Japanese designer, sometimes you can fall back on the rules and to make an unexpected move - to abandon the usual form of straight or cross-shaped slot. This project is implemented in cooperation with the designer Komuro Seisakusho, plant for the production of screws in East Osaka.

At the moment, there are a large number of standards of the metal piece. There is a classical direct slot, there is a slot in the form of stars, there is a cross-shaped slot, a polygon, etc. A Japanese designer offers its own slot, simple and clear to everyone - in the form of a smiley face.

Of course, to work with such a screw is not suitable for either a screwdriver or bit - they must have an appropriate projection. Usually tool such detail or to screw or unscrew. However, by and large, what does it matter if a tiny cog cheer up, even just a little bit? Besides the unique parts can carry and practical benefits: for example, it can protect the structure from "skillful hands" or simply to emphasize the originality of the assembly.

In principle, the idea is not new Japanese just before nobody paid much attention to a custom slot. Some manufacturers deliberately use the special "secret" form of slot titled Clutch head. This head has ground off the edge, so you can only work with a screwdriver clockwise.

For example, to analyze some models of the line filter APC, will have to break the case, since there is also made an inclined slot. This item can only twist and unscrew the usual way will fail.

The screw - a very simple and reliable fastening element. However, it can be "broken". His slot can be broken by excessive force applied in the process of loosening, and the thread itself may be disrupted. Giving forecasts - a thankless task, but still there is hope that in the future these problems will be much less. In 2002, Japanese scientists company Mitsubishi Heavy Industries have demonstrated "improved" version of the screw. They used it to create a polymer material with a memory effect.

In the normal state, this member has a classical geometry with a screw thread. But it is worth it to heat up and spiral notch disappears - screw straightens up, turning into a rod that you can easily pull out of the slot. The cost of this element higher than conventional steel screws - probably for this reason that the "eternal" screw is not widespread. However, the invention of Japanese engineers gives an idea of what awaits us in the future.

If you look at the rotating thread such as a drill, there will be an optical illusion - the subject of "alive" and the impression that the helical notch moves. Perhaps this illusion and suggested a wonderful man mechanism alternative to the wheel - Screw Rotary mover. This Moving transport element got its name from the German word Schnecke, which translates as "snail". Use as a rotating helical element move rods allowed the inventors to design a new type of all-terrain vehicles.

Actually, all-terrain vehicles called rotary snow machines would not be entirely correct, because such vehicles are not able to move on any ground. For example, in a conventional asphalt or concrete road shnekohod not show its advantages - it will be sluggish and slow. But is such a machine to be on marshy or snowy terrain, and it is easy to take place where other vehicles are hopelessly bogged down.

Even today, construction shnekohoda surprising for those who have not seen this class of machine, it was too strange looks such devices.

But history shnekohodov begins much earlier than you might expect. For example, in the USSR, the engineers were well aware of the potential of this type of machinery. Their production has not been established in large numbers, but some copies were in service in the Soviet army. For the same reason, the national press has focused on the unusual design of all-terrain vehicles. But the mention of them we find a completely unusual place. In 1958, in the journal "Youth" was first published children's book Nikolai Nosov "Dunno in the Sun City", where the author describes the surprisingly accurate rotary snow machines, calling them "spiralehodami».

Curiously, the first national cross-country vehicles with screws were developed only a decade after the release of this book. They were engaged ZIL engineers under the leadership of the Soviet designer Vitaly A. Grachev.

Henry Ford, owner of the legendary Ford Motor Company, was one of the first who thought about the mass production of machines with rotary snow gear. At the beginning of last century, he sought to expand production and began to experiment with different types of tractors. Shareholders of the company, which owned 41 shares of 5 percent, Ford strongly hindered in its "creative research". Therefore, to continue the search for a new, jointly with his son Henry had to create a separate company Henry Ford and Son, which later began to use the brand "Fordsan» (Fordson). One of the conceptual fordsanov (or Fordson - so called in the Soviet version of the tractors manufactured in the late twenties of the XX century under license) had an unusual propulsion - a pair of rotating spiral cylinders. The model was named Armstead Snow Motor, or "snow devil».

Chronicle of 1929 very clearly shows the benefits of shnekohoda on snow-covered terrain. The video shows a working model of the tractor absolutely fordsana that can easily take place where the horse is hopelessly mired in the snowdrifts.

And after all, who first invented shnekohod? Perhaps it was the Swiss Iakob Morath, who in 1899 patented a machine in the United States with a screw drive for doing farm work. Conceived as it was earlier (according to some sources - in 1868). Russia has also been patented model sledge, who used the same principle as its author was F. Dergint.

Claus Philipp Maria Schenk Graf von Stauffenberg went down in history primarily because his name figured in the list of indicted war Wehrmacht, convicted on the conspiracy against Hitler. But this man's life there is still one thing that is of direct relevance to our topic.

It is no secret that the German High Command has stimulated a number of projects to create new weapons and equipment for the German army. Claus von Stauffenberg led one such secret research. Under his boat it was designed to move underground. Yes, you heard right - just below the ground. Actually, that's strange? Rigs that make tunnels have long been known. The question was how to make a mobile unit. At the heart of this amazing invention of the project lay a German engineer Wilhelm von Verna, who patented it in 1933. Such a boat was crowned with a huge powerful drill, which allows the vehicle to literally bump into solid rock.

When the funds were allocated for the project, it was assumed that these boats will have time to make ground for the invasion of Britain, guiding them under the English Channel. According to calculations by the German engineers, the ship could move a team of five people and carry 300 kg warhead in, moving under the ground at a speed of 7 km / h. But as you know, "Operation Sea Lion" did not take place, and Hitler himself considered it more prudent to bet on Air Force. Ultimately, the development of the German underground boat was frozen.

After the war, the Soviet Union, such studies were conducted on developments Shal'nikov Trebeleva. Our compatriot long and detailed studied similar projects overseas colleagues and tried to systematize information about podzemohodah. As a result, Soviet scientists concluded that the best way to create an underground boat - to try to find an alternative to the usual snap mechanism that was used in the construction of almost all underground boat at the time.

To move away from the stereotype of an underground boat, scientists began to look closely to ordinary moles. Animal experiments were carried out quite a few, in which scientists were observing and trying to understand how the moles so quickly makes its way underground. It turned out that in the process of digging tunnels the mole involves not only the front paws, but the whole body. Head and front paws, he performs the rotation and forward movement, and the hind legs pushed off the ground.

A similar principle has been implemented and in the car Trebeleva, where instead of the hind legs used jacks. Together with the designers and Baskin A. Kirillov Trebelev I could make a machine that worked with an efficiency of 300 revolutions per minute, giving the potential for promotion to 10 meters per hour. And that was just the beginning. Later, in the Soviet Union it was designed and built a real underground cruiser, codenamed "Combat mole».

This machine is brilliantly passed the first test, but on the second attempt to test the functionality of the device, in the Ural Mountains, there was an explosion, which killed the entire crew of underground vessel. This promising development has been suspended.

That screw - a piece for fixing structural elements, it is obvious to all. But as you can see, the scope of this megapoleznoy tiny things much broader.

--img26--