853

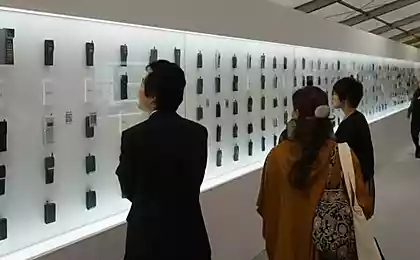

Testing of mobile phones (33 photos)

In a quiet business park, the English town of Farnborough, engineer Kevin Smith every day engaged in one and the same thing: damage of cellular phones.

"If we do not break it, consider that we have not coped with their work," says the man who occupied an unusual profession - deliberately damage telephone.

The main task of each working day Smith - to help verify the handsets on the strength, and to figure out how to behave in the apparatus of force majeure.

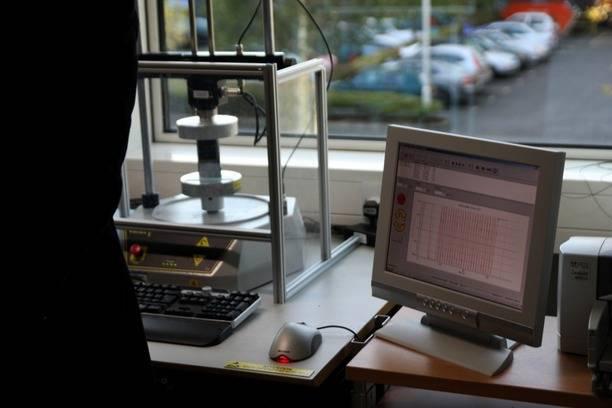

"Currently, we practice about 200 different tests, and if we spent one test after the other hand, then we would have taken about five years to get rid of the full cycle. Our tests allow you to check the tube everything from shutter button and ending with the camera, "Smith tells us, starting to talk about their work.

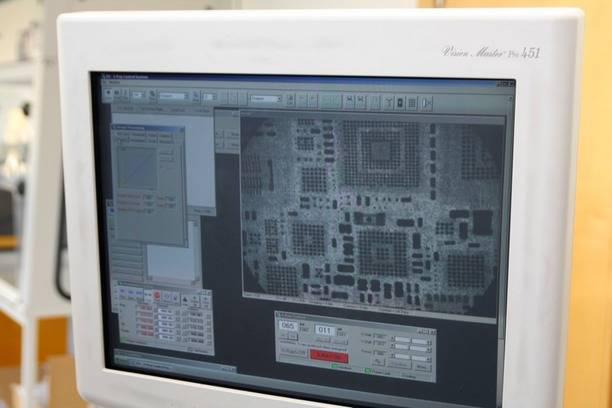

Of course, we do not need 5 years to verify the phone, but checking about 300-500 samples handsets at a time, we spend approximately 8 weeks (if they pass this test once). It saves a lot of time that testing department works hand in hand with the designers, in a building next door to the very beginning of the project. Even when a new model handset is not already in the material sense of the word, Kevin and his merry band of destroyers break the material directly on a computer monitor in the program simulates the mechanical action.

"We check all factors, starting with the simulation of falling tube from a low altitude and ending simulation to extreme temperatures and humidity," says Smith.

"Once we progonim these tests, we are fully confident that the customer can buy the handset in any country (with any climate) and take her to any point on the globe».

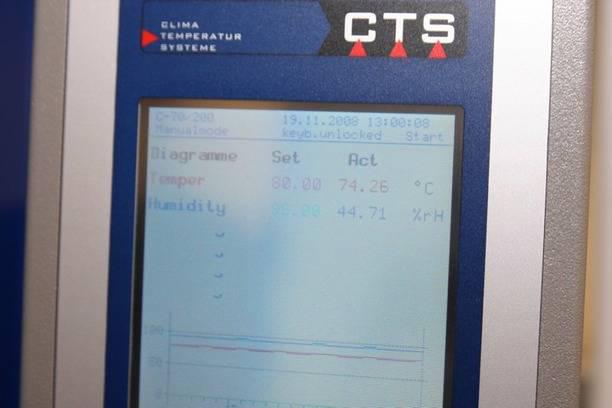

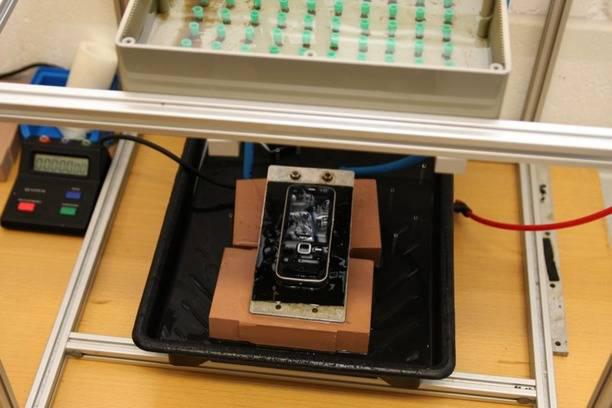

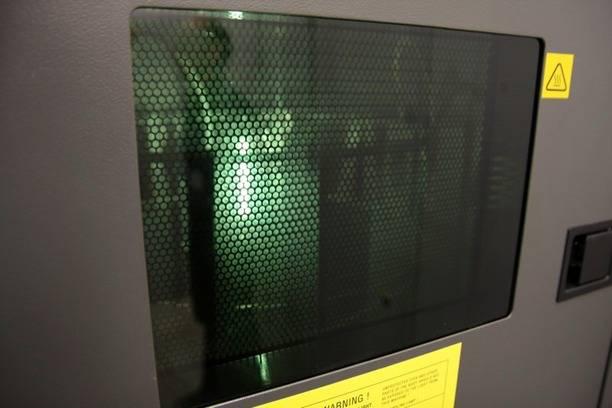

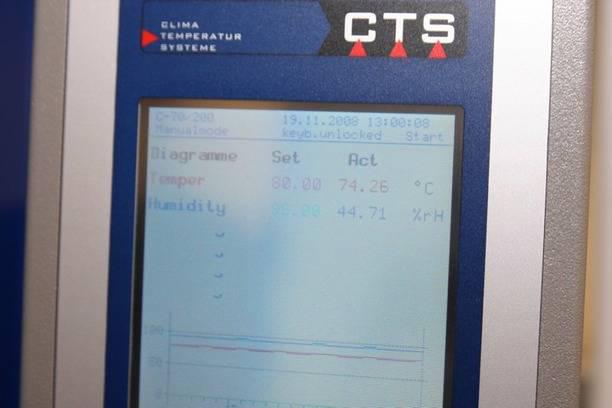

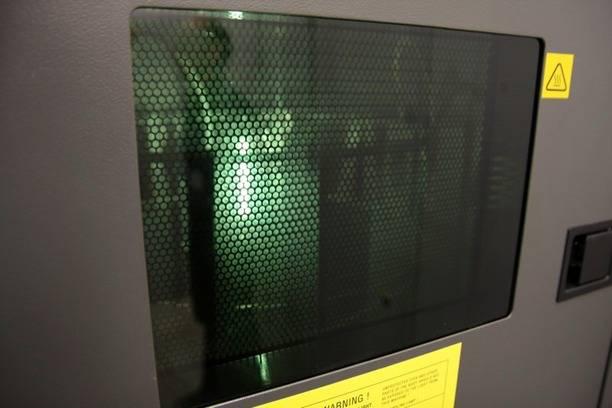

This device allows you to work on the tube temperatures to 85 degrees Celsius and humidity up to 95%.

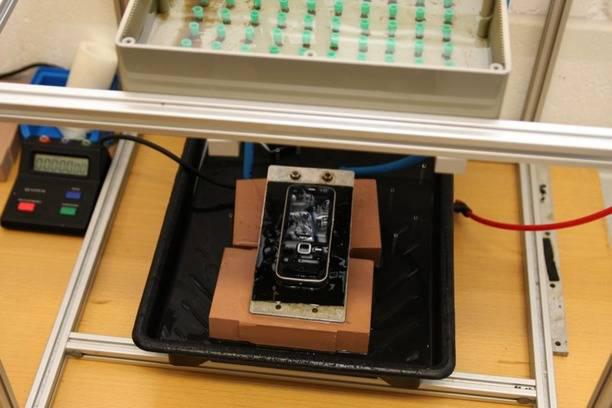

The handsets go through the process "sauna».

And it is very hot.

Yeah, behind this door -40.

This camera is so cold that on the unit formed ice crust, but tests are continuing. We will do severe test, the tube is guaranteed to have been tested in 11 test centers around the world. What does "severely tested"? We subject the tube to temperatures from 85 degrees Celsius to -40, there is a steady phone to moisture up to 95% and then to powder all the tests for resistance to corrosion, rain and direct sunlight, and it is only "weather" department. < br />

The Department of studying resistance falls handsets thousands of times dropped from a great height to 5 hours, and remove this procedure on a video camera value of 50 000 pounds that can shoot up to 100 000 frames per second!

Plight devices exposes them fall over and over again.

A little rain to simulate London.

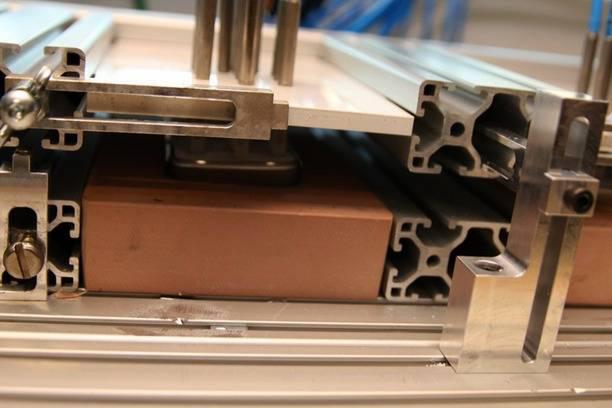

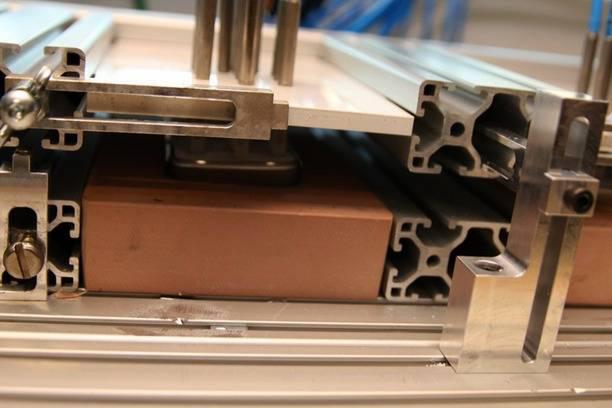

No supernatural equipment. In the arsenal of Smith and his team have even tests such as the test for the friction to simulate the wearing of the tube in the pocket of your jeans, and an abrasive test showing keys and coins in your pockets - 5 hours dings and strum a row, instead of five minutes, which you enough to walk to his car.

This machine tests the machines for resistance to "polishing" the display of your jeans.

Telephone in the "washing machine».

These figures are as coins and keys in your pocket - 5 hours of intensive bombardment device.

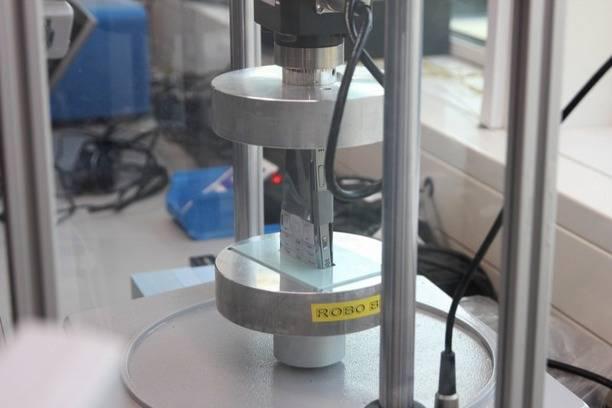

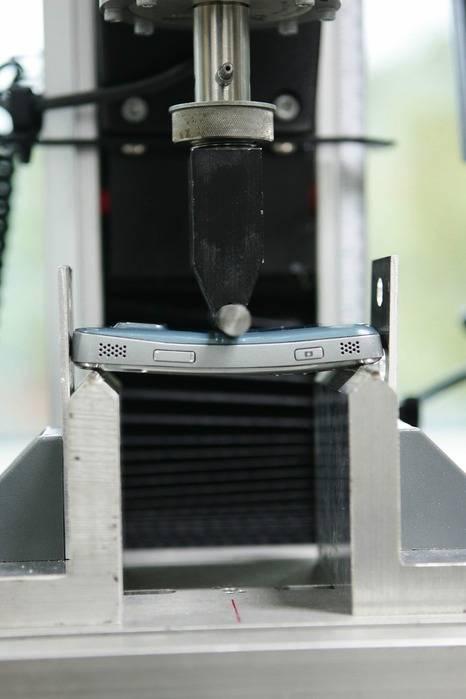

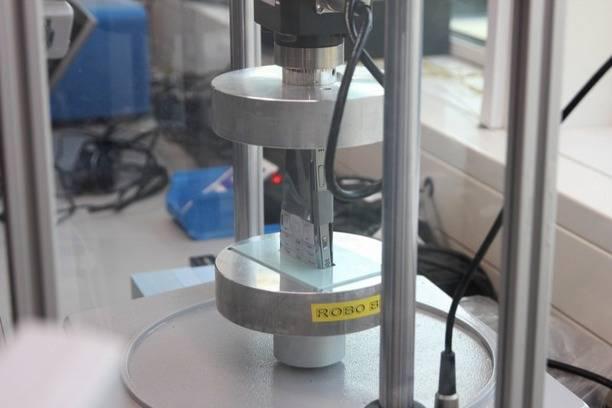

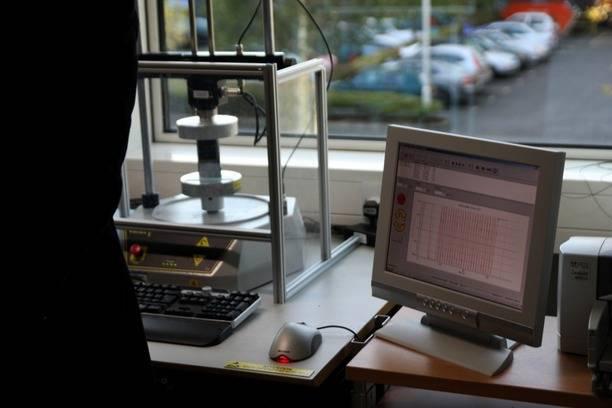

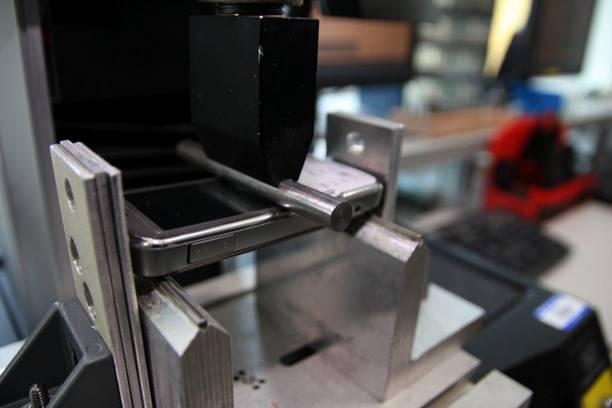

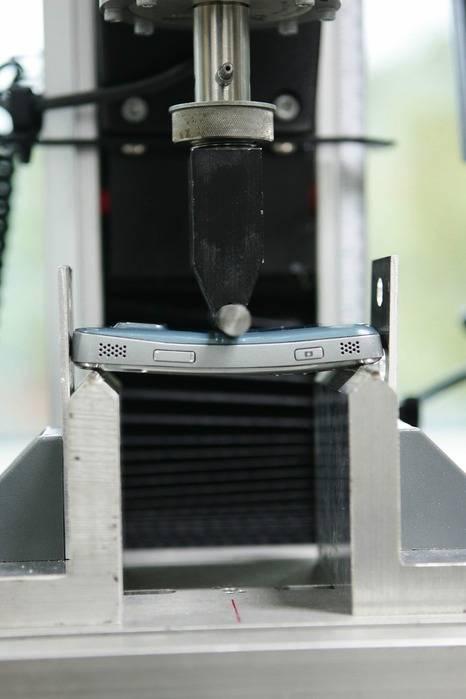

You ask, what is our favorite test? Test pressure and stretching the phone, simulating the pressure exerted on the tube located under the weight of 95 kg., Not to mention another test involving "machine-juicer».

Tools evil genius.

Measurements taken from the machine, juicer.

Yeah, actually bends

Long hair - not a requirement, but it helps to work.

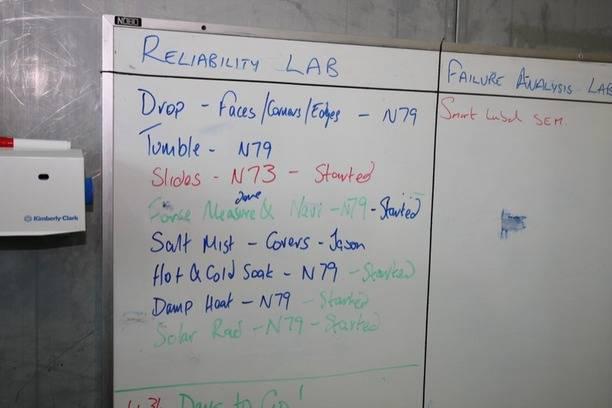

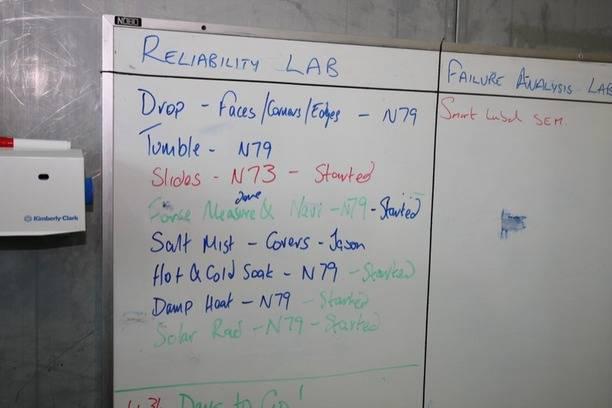

Wrecking the plans are planned for the week.

On the telephone is under pressure of 95 kg.

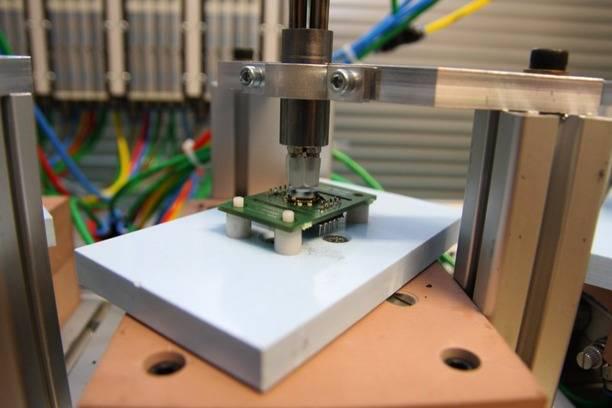

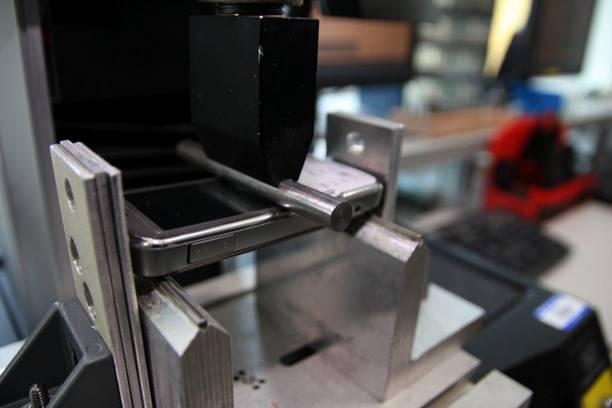

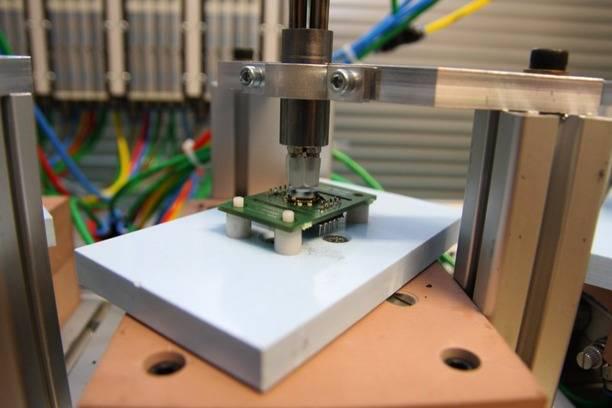

If the phone can stand before all of the above tests, the engineers get to buttons, switches, sockets, and various moving parts. Robots are an infinite number of times the button is pressed, the shutter is pushed back down and video cameras - you call the part of the phone, engineers are trying to break it, constantly checking the results, recording how and when it breaks down.

Test the keyboard.

Another test for the mechanical stability of the moving parts.

Again, the strength test the keyboard.

Another test button press.

Do you think that all these tests enough? You are not right. Smith puts the phone the toughest test of all: a test called "Gorilla". No, Smith travels to London Zoo, he and his engineers are trying to break down the devices with their bare hands. "Can we break into this slot with a fingernail? What happens if we press down a little harder? "Smith tells us, taking a cell phone from his pocket, that when all the tests pass, he gives his two-year-tube baby, that he" played "with her builders. Test Result hopes Smith, it's a phone that does not fall apart on the details when you pull it out of the package.

Phones are exposed to direct sunlight, it is done to find out how "fades" display with time.

Under the microscope.

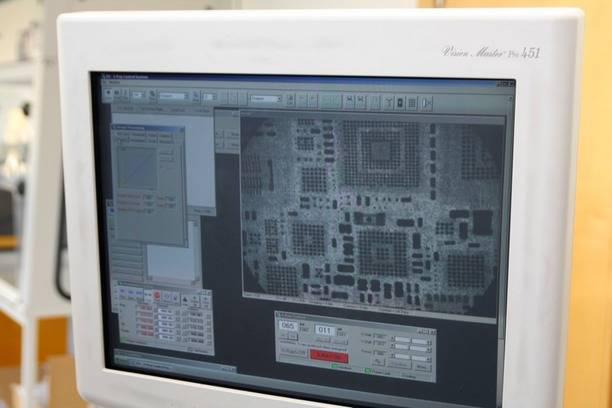

Phones are placed in X-ray machine to disassemble them.

Sand in the picture is similar to plywood. This test is designed to show what would happen to the machine when dirt gets inside.

We analyze the information.

X-ray machine in action

Is phones so bent?

Testing the navigation buttons.

"If we do not break it, consider that we have not coped with their work," says the man who occupied an unusual profession - deliberately damage telephone.

The main task of each working day Smith - to help verify the handsets on the strength, and to figure out how to behave in the apparatus of force majeure.

"Currently, we practice about 200 different tests, and if we spent one test after the other hand, then we would have taken about five years to get rid of the full cycle. Our tests allow you to check the tube everything from shutter button and ending with the camera, "Smith tells us, starting to talk about their work.

Of course, we do not need 5 years to verify the phone, but checking about 300-500 samples handsets at a time, we spend approximately 8 weeks (if they pass this test once). It saves a lot of time that testing department works hand in hand with the designers, in a building next door to the very beginning of the project. Even when a new model handset is not already in the material sense of the word, Kevin and his merry band of destroyers break the material directly on a computer monitor in the program simulates the mechanical action.

"We check all factors, starting with the simulation of falling tube from a low altitude and ending simulation to extreme temperatures and humidity," says Smith.

"Once we progonim these tests, we are fully confident that the customer can buy the handset in any country (with any climate) and take her to any point on the globe».

This device allows you to work on the tube temperatures to 85 degrees Celsius and humidity up to 95%.

The handsets go through the process "sauna».

And it is very hot.

Yeah, behind this door -40.

This camera is so cold that on the unit formed ice crust, but tests are continuing. We will do severe test, the tube is guaranteed to have been tested in 11 test centers around the world. What does "severely tested"? We subject the tube to temperatures from 85 degrees Celsius to -40, there is a steady phone to moisture up to 95% and then to powder all the tests for resistance to corrosion, rain and direct sunlight, and it is only "weather" department. < br />

The Department of studying resistance falls handsets thousands of times dropped from a great height to 5 hours, and remove this procedure on a video camera value of 50 000 pounds that can shoot up to 100 000 frames per second!

Plight devices exposes them fall over and over again.

A little rain to simulate London.

No supernatural equipment. In the arsenal of Smith and his team have even tests such as the test for the friction to simulate the wearing of the tube in the pocket of your jeans, and an abrasive test showing keys and coins in your pockets - 5 hours dings and strum a row, instead of five minutes, which you enough to walk to his car.

This machine tests the machines for resistance to "polishing" the display of your jeans.

Telephone in the "washing machine».

These figures are as coins and keys in your pocket - 5 hours of intensive bombardment device.

You ask, what is our favorite test? Test pressure and stretching the phone, simulating the pressure exerted on the tube located under the weight of 95 kg., Not to mention another test involving "machine-juicer».

Tools evil genius.

Measurements taken from the machine, juicer.

Yeah, actually bends

Long hair - not a requirement, but it helps to work.

Wrecking the plans are planned for the week.

On the telephone is under pressure of 95 kg.

If the phone can stand before all of the above tests, the engineers get to buttons, switches, sockets, and various moving parts. Robots are an infinite number of times the button is pressed, the shutter is pushed back down and video cameras - you call the part of the phone, engineers are trying to break it, constantly checking the results, recording how and when it breaks down.

Test the keyboard.

Another test for the mechanical stability of the moving parts.

Again, the strength test the keyboard.

Another test button press.

Do you think that all these tests enough? You are not right. Smith puts the phone the toughest test of all: a test called "Gorilla". No, Smith travels to London Zoo, he and his engineers are trying to break down the devices with their bare hands. "Can we break into this slot with a fingernail? What happens if we press down a little harder? "Smith tells us, taking a cell phone from his pocket, that when all the tests pass, he gives his two-year-tube baby, that he" played "with her builders. Test Result hopes Smith, it's a phone that does not fall apart on the details when you pull it out of the package.

Phones are exposed to direct sunlight, it is done to find out how "fades" display with time.

Under the microscope.

Phones are placed in X-ray machine to disassemble them.

Sand in the picture is similar to plywood. This test is designed to show what would happen to the machine when dirt gets inside.

We analyze the information.

X-ray machine in action

Is phones so bent?

Testing the navigation buttons.