500

As I washed down the pan

Probably, Japanese have already seen everything, and it does not surprise. Construction of houses, furnish of apartments, making the stone flash drives, monitors repair by replacing the pot-bellied capacitors transplant organs lost with blue tape and stuff ... So not much claim to exclusivity of its themes.

But I wanted to share his recent photographic creativity.

25 pictures.

The fact is that at present rented accommodation, and want to buy kitchen utensils least. Razumeetsya- post is not about how to save money on buying a frying pan. Because if you calculate the spent material resources, as well as the time ... you get a very severe cost, which the budget can not be called. Therefore, let it be a story about technocratic humorous sketches. Boredom. For the love of ...

rukozhopstvu However, I have always aspired to a different life creative ideas. In addition, long time bathed in the blood of the heart, looking at both the landfill has sent hundreds of kilograms of usable rolled metal, stainless steel, aluminum.

Throw-known postulate of "Russian - never give up and never pay» ...

Why buy in the store for me was not a method. And if, for example, the jeans I come off the button, I was easier to do it from the copper itself, rather than shove it to the store to buy. (Of course, this refers to the time when I was on a business trip away from home. Because if I'm at home, engaged hyuney once, and there is no need.)

Catching preparing food, said that on the thin aluminum frying pan ketayskoy - one bullying. In the center of the temperature more ... Along the edges - lower. Temperature control on plite- hardly helps.

Therefore, for a long time thinking about making harsh pan with a thick bottom, which has a thermal inertia. Material - stainless steel. (Mark I do not remember it, but we know that for the repair of the fish factories and fishing boats to be used is not harmful to humans steel, because after a bad steel, no one will take the fish.)

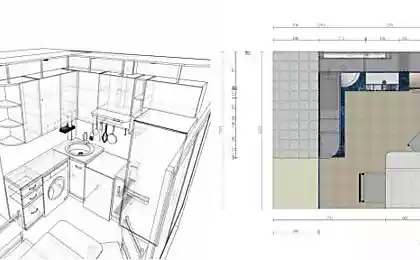

At first the idea was to carve out a single piece of metal ... but bet the pros and cons ... decided it was best to collect two basic elements, that is, construction will be welded. As that:

Round pancake thickness of 15mm and height of 30mm ring. Damn it is the bottom and out of the ring will turn the rim pans. These two elements decided to cook. Next, get konstruktsiyu- grind lathe ... To illustrate the ideas attach rukozhop.

Thus, the manufacturing process is as follows:

Cut the pancake made of stainless steel with a diameter of 255 mm and a thickness of 15 mm.

It is welded to the ring ... technological quality and beauty of welding is not required here, because it will then be cut.

For this damn ring fastened to the lathe chuck and process the contact surface to the ring. And also sharpen chamfer to weld.

Fortunately there was a ring of stainless steel desired diametra- little more than a pancake.

Source:

But I wanted to share his recent photographic creativity.

25 pictures.

The fact is that at present rented accommodation, and want to buy kitchen utensils least. Razumeetsya- post is not about how to save money on buying a frying pan. Because if you calculate the spent material resources, as well as the time ... you get a very severe cost, which the budget can not be called. Therefore, let it be a story about technocratic humorous sketches. Boredom. For the love of ...

rukozhopstvu However, I have always aspired to a different life creative ideas. In addition, long time bathed in the blood of the heart, looking at both the landfill has sent hundreds of kilograms of usable rolled metal, stainless steel, aluminum.

Throw-known postulate of "Russian - never give up and never pay» ...

Why buy in the store for me was not a method. And if, for example, the jeans I come off the button, I was easier to do it from the copper itself, rather than shove it to the store to buy. (Of course, this refers to the time when I was on a business trip away from home. Because if I'm at home, engaged hyuney once, and there is no need.)

Catching preparing food, said that on the thin aluminum frying pan ketayskoy - one bullying. In the center of the temperature more ... Along the edges - lower. Temperature control on plite- hardly helps.

Therefore, for a long time thinking about making harsh pan with a thick bottom, which has a thermal inertia. Material - stainless steel. (Mark I do not remember it, but we know that for the repair of the fish factories and fishing boats to be used is not harmful to humans steel, because after a bad steel, no one will take the fish.)

At first the idea was to carve out a single piece of metal ... but bet the pros and cons ... decided it was best to collect two basic elements, that is, construction will be welded. As that:

Round pancake thickness of 15mm and height of 30mm ring. Damn it is the bottom and out of the ring will turn the rim pans. These two elements decided to cook. Next, get konstruktsiyu- grind lathe ... To illustrate the ideas attach rukozhop.

Thus, the manufacturing process is as follows:

Cut the pancake made of stainless steel with a diameter of 255 mm and a thickness of 15 mm.

It is welded to the ring ... technological quality and beauty of welding is not required here, because it will then be cut.

For this damn ring fastened to the lathe chuck and process the contact surface to the ring. And also sharpen chamfer to weld.

Fortunately there was a ring of stainless steel desired diametra- little more than a pancake.

Source: