861

How do the rubble

The author writes, dedmaxopka:

I'll tell you how to make gravel.

Not far from the claim. Mountain in the Novosibirsk region produce rubble. It was possible to go there and shoot a little production.

1. The largest producer of crushed stone for the Ural

And so, at first.

Engaged in production of crushed stone of "Quarry", he, as I wrote above, not only is the largest in the Novosibirsk region, but also in the Urals. Production in general, of the order of 5 million tons per year. The main mission of the company is to meet the needs of non-metallic building materials concrete products manufacturers, construction companies, road construction companies and organizations involved in the construction of railway tracks, etc.

Factories produce high quality stone quarry gravel from dense rocks of various factions - and diabase rocks albitophyre.

Where to use the rubble? The construction of roads, runways, is used as ballast railway track, filling concrete for reinforced concrete pressure pipes, critical structures of buildings and bridge structures.

In general, rubble irreplaceable product. How did it do?

2. Colorful pointers companies

In our case, everything begins in the quarry, where open-pit mined the right rocks (diabase and albitofir). First monoliths separated from the array through the blasting (drilled holes, laying explosives and bang), then split monoliths technology into smaller rocks and transported to the plant.

3. According to the terms worked out, the quarry operates more than a dozen years.

4. According to the most career not walking, but stood next technique: the left one that hews large rocks into smaller ones, and the right one that bore holes. Dog guarding the whole thing.

5.

To transport the stone used BelAZ, in which only one wheel more than me. For their journey built a separate technological road, so the car did not go on the road and do not spoil the roadbed.

Here they are handsome:

6.

7.

Next Belaz unloads of rock that enters the primary crusher, which grinds more stones.

8. The main crusher. Inside is a strong roar of the stones to crack. This device is operated by one person.

Rock rocks as a feedstock for the production of stone materials have been in the initial state a number of necessary mechanical and technological properties. Because the entire production process is not as elaborate. After primary crusher crushed rock gets into a vicious cycle of production. As the conveyor belt is transported to devices called "Rumble" that sort all the "stone traffic" in size.

9. Start the conveyor system.

10. Those are the "Rumble", which sort the stones in size. You can guess why these devices are named so.

After sorting the breed sent to different conveyor belts in different mills (large, medium and small), which make the product itself - rubble (large, small) and screening. Then you need to somehow transport products? This was after photos of the production.

11. crushers after "Grokhotov»

12. Screenings. It may seem that screening - is trash after production, but it is not. Screenings - also demanded products.

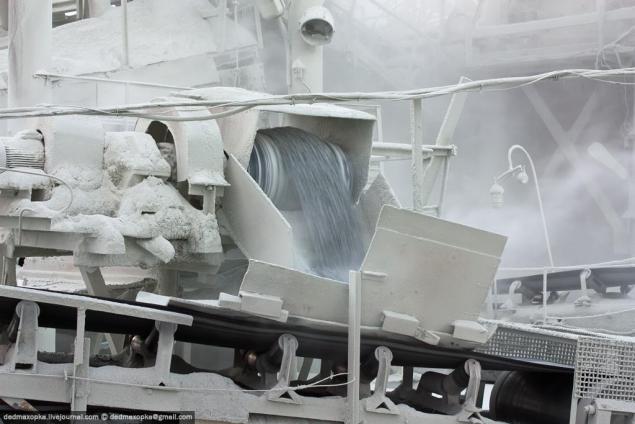

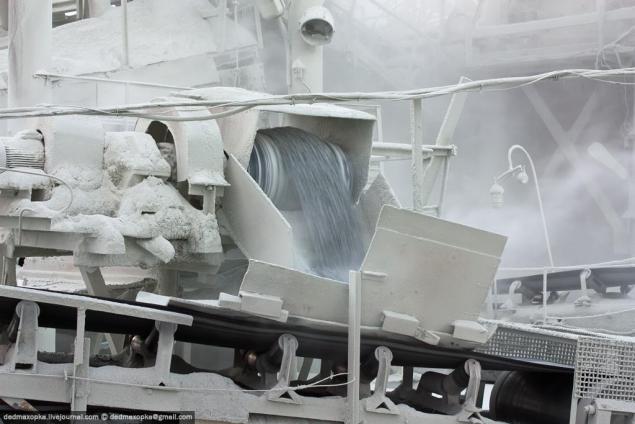

People working on this production retire early because of severe working conditions. The thing is that the air is dust, it is everywhere, it is worth a little stay in the area and has all white. The land in the district, in the snow.

13. Everything in the dust. It's not even in his own way beautiful.

14.

There are many varieties of rubble - do it from different rocks of different sizes (Table guest) and varying flakiness.

Species: granite, gravel, limestone, secondary, slag.

15.

Just rubble have several options, most of which depend on the raw material and the place where it was made production.

The main parameters of rubble are: frost resistance, strength, flakiness and radioactivity.

16. Screenings

17.

18. Technique

19.

By the time it was getting dark.

And so, after the products are ready, it must be transported to warehouses or pack. It is produced with the help of the railway. Pulls the part of the dump cars (a type of car), and then the whole point of the truck.

20. The composition of

21. Frankly, I think the process will be somewhat different from the present.

22.'ll get closer

23. How long

24.

After loading the composition weighed on special scales rail.

25. The same scales

26. For all the processes vigilantly Manager.

After weighing the composition delivers products to shops where rubble modify, warehoused, pack, give.

27. After the composition.

28. All covered in dust. On the right the mountain of rubble

And now, we are on the final stage of production. Here, modify, package, distribute, warehoused rubble.

29.

30. There are conveyor belts that lead to the bunker with rubble, something like a warehouse. On the left, where the light is, distribute rubble in KAMAZ.

We went into one of the rooms.

31. Perhaps there was a kind of failure. Here is a brand new colored shaft.

32. The shop is very noisy.

33. Finally the frame with the pipe. All fields in the dust. I wonder whether there grow anything?

via

Source:

I'll tell you how to make gravel.

Not far from the claim. Mountain in the Novosibirsk region produce rubble. It was possible to go there and shoot a little production.

1. The largest producer of crushed stone for the Ural

And so, at first.

Engaged in production of crushed stone of "Quarry", he, as I wrote above, not only is the largest in the Novosibirsk region, but also in the Urals. Production in general, of the order of 5 million tons per year. The main mission of the company is to meet the needs of non-metallic building materials concrete products manufacturers, construction companies, road construction companies and organizations involved in the construction of railway tracks, etc.

Factories produce high quality stone quarry gravel from dense rocks of various factions - and diabase rocks albitophyre.

Where to use the rubble? The construction of roads, runways, is used as ballast railway track, filling concrete for reinforced concrete pressure pipes, critical structures of buildings and bridge structures.

In general, rubble irreplaceable product. How did it do?

2. Colorful pointers companies

In our case, everything begins in the quarry, where open-pit mined the right rocks (diabase and albitofir). First monoliths separated from the array through the blasting (drilled holes, laying explosives and bang), then split monoliths technology into smaller rocks and transported to the plant.

3. According to the terms worked out, the quarry operates more than a dozen years.

4. According to the most career not walking, but stood next technique: the left one that hews large rocks into smaller ones, and the right one that bore holes. Dog guarding the whole thing.

5.

To transport the stone used BelAZ, in which only one wheel more than me. For their journey built a separate technological road, so the car did not go on the road and do not spoil the roadbed.

Here they are handsome:

6.

7.

Next Belaz unloads of rock that enters the primary crusher, which grinds more stones.

8. The main crusher. Inside is a strong roar of the stones to crack. This device is operated by one person.

Rock rocks as a feedstock for the production of stone materials have been in the initial state a number of necessary mechanical and technological properties. Because the entire production process is not as elaborate. After primary crusher crushed rock gets into a vicious cycle of production. As the conveyor belt is transported to devices called "Rumble" that sort all the "stone traffic" in size.

9. Start the conveyor system.

10. Those are the "Rumble", which sort the stones in size. You can guess why these devices are named so.

After sorting the breed sent to different conveyor belts in different mills (large, medium and small), which make the product itself - rubble (large, small) and screening. Then you need to somehow transport products? This was after photos of the production.

11. crushers after "Grokhotov»

12. Screenings. It may seem that screening - is trash after production, but it is not. Screenings - also demanded products.

People working on this production retire early because of severe working conditions. The thing is that the air is dust, it is everywhere, it is worth a little stay in the area and has all white. The land in the district, in the snow.

13. Everything in the dust. It's not even in his own way beautiful.

14.

There are many varieties of rubble - do it from different rocks of different sizes (Table guest) and varying flakiness.

Species: granite, gravel, limestone, secondary, slag.

15.

Just rubble have several options, most of which depend on the raw material and the place where it was made production.

The main parameters of rubble are: frost resistance, strength, flakiness and radioactivity.

16. Screenings

17.

18. Technique

19.

By the time it was getting dark.

And so, after the products are ready, it must be transported to warehouses or pack. It is produced with the help of the railway. Pulls the part of the dump cars (a type of car), and then the whole point of the truck.

20. The composition of

21. Frankly, I think the process will be somewhat different from the present.

22.'ll get closer

23. How long

24.

After loading the composition weighed on special scales rail.

25. The same scales

26. For all the processes vigilantly Manager.

After weighing the composition delivers products to shops where rubble modify, warehoused, pack, give.

27. After the composition.

28. All covered in dust. On the right the mountain of rubble

And now, we are on the final stage of production. Here, modify, package, distribute, warehoused rubble.

29.

30. There are conveyor belts that lead to the bunker with rubble, something like a warehouse. On the left, where the light is, distribute rubble in KAMAZ.

We went into one of the rooms.

31. Perhaps there was a kind of failure. Here is a brand new colored shaft.

32. The shop is very noisy.

33. Finally the frame with the pipe. All fields in the dust. I wonder whether there grow anything?

via

Source: