461

How to lay paving slabs with their hands

There are several technologies how to lay tile. It is possible — on a layer of cement mixture and eventually the entire surface the surface turns into a monolith. But happens and so that the tiles will need to disassemble. Therefore, the best, most efficient way of paving on a sand base.

For this you will need a trowel, metal or wood stakes, string, level, rubber mallet, wood mallet, a hose, rake, broom, profiles, manual rammer, channel, sand, crushed stone of fraction 10-20 (20-50) or gravel, cement 400 (500) or the dry mixture, geotextile, sidewalk tile with a thickness of 50-60 mm, for Parking — 70-80 mm, kerb stone.

First draw the plan drawing. Based on it, calculate how much you need the tiles, sand, crushed stone or gravel, cement.

Using a ruler and a stick, cord, or string, mark the tracks and platforms for laying tiles. Check out all of the "in kind" through the plan.

To then not have to cut the tiles, you need the length and width of places of paving to do multiple dimensions of the purchased tiles. It is better to avoid such cutting, the coating to be more durable.

First, install curbs. They may be slightly above or flush with the track. Their main task — to keep the carpet from raveling.

The main thing is to thoroughly implement the base under the tile. It is a guarantee of quality and durability of future tracks.

First remove the old coating or if it is not, — sod to a depth of 15-20 cm And no roots or seeds! It is necessary to plan the flow of water drainage, especially in clay soil. So that water flowed on the edge of the site, make a transverse or longitudinal slopes.

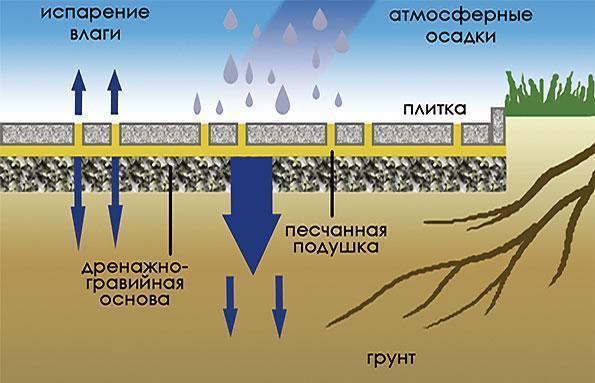

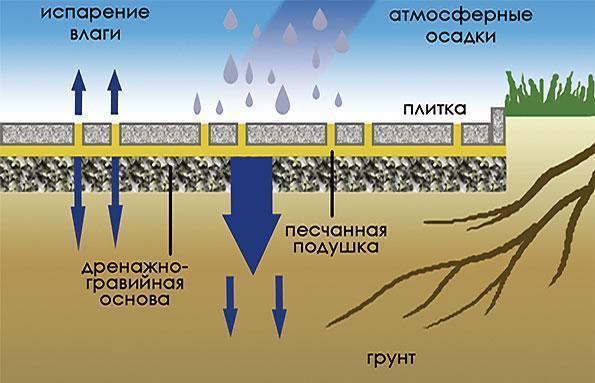

In any case, whether the tile is placed in a liquid solution, dry mix or sand as a base is always used crushed stone or sand cushion.

First, we stamp and put the crushed stone or gravel. Top intermediate sand layer with a thickness of 3-5 cm Between the gravel and sand can be laid geotextile to ensure free flow of water.

Rammer on a Sunny day is in a couple of hours, but in cloudy weather the next day.

As the top layer of base you can use ready dry mix or prepared by cement-sand mixture in the ratio of 1 to 3. Pour the mixture with a layer of 3-4 cm with a rake and level the surface. A channel, perform the final leveling of the surface.

Attention! The tile should be laid from itself. Each tile should be possible to firmly join the previous one. Clearance of 1-2 mm is sufficient to fill the dry mixture or sand. Laid tile stamped wooden mallet. If the bar sags, it puts under it with a trowel and flatten the sand with a tamper. At the end of the stacking lugs align with a rubber mallet.

And another tip. Sand mixed with impurities of any salts cannot be used, especially when laying colored tiles: due to impurities in the future on the track can appear ugly white stains.

Having laid the tile, again check the site. By removing ledges and irregularities, cover all seams with a dry cement-sand mixture, sweep away the excess and hose with a spray humidified mixture into the gaps.

Paving requires maintenance. It should be cleaned regularly, from time to time to wash. And in the winter to clean snow from the tracks, you cannot use a metal tool to the surface of the tiles. It is not necessary to break the tile lacquers, paints and other chemicals. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: proftula.ru/articles/187/30124/

For this you will need a trowel, metal or wood stakes, string, level, rubber mallet, wood mallet, a hose, rake, broom, profiles, manual rammer, channel, sand, crushed stone of fraction 10-20 (20-50) or gravel, cement 400 (500) or the dry mixture, geotextile, sidewalk tile with a thickness of 50-60 mm, for Parking — 70-80 mm, kerb stone.

First draw the plan drawing. Based on it, calculate how much you need the tiles, sand, crushed stone or gravel, cement.

Using a ruler and a stick, cord, or string, mark the tracks and platforms for laying tiles. Check out all of the "in kind" through the plan.

To then not have to cut the tiles, you need the length and width of places of paving to do multiple dimensions of the purchased tiles. It is better to avoid such cutting, the coating to be more durable.

First, install curbs. They may be slightly above or flush with the track. Their main task — to keep the carpet from raveling.

The main thing is to thoroughly implement the base under the tile. It is a guarantee of quality and durability of future tracks.

First remove the old coating or if it is not, — sod to a depth of 15-20 cm And no roots or seeds! It is necessary to plan the flow of water drainage, especially in clay soil. So that water flowed on the edge of the site, make a transverse or longitudinal slopes.

In any case, whether the tile is placed in a liquid solution, dry mix or sand as a base is always used crushed stone or sand cushion.

First, we stamp and put the crushed stone or gravel. Top intermediate sand layer with a thickness of 3-5 cm Between the gravel and sand can be laid geotextile to ensure free flow of water.

Rammer on a Sunny day is in a couple of hours, but in cloudy weather the next day.

As the top layer of base you can use ready dry mix or prepared by cement-sand mixture in the ratio of 1 to 3. Pour the mixture with a layer of 3-4 cm with a rake and level the surface. A channel, perform the final leveling of the surface.

Attention! The tile should be laid from itself. Each tile should be possible to firmly join the previous one. Clearance of 1-2 mm is sufficient to fill the dry mixture or sand. Laid tile stamped wooden mallet. If the bar sags, it puts under it with a trowel and flatten the sand with a tamper. At the end of the stacking lugs align with a rubber mallet.

And another tip. Sand mixed with impurities of any salts cannot be used, especially when laying colored tiles: due to impurities in the future on the track can appear ugly white stains.

Having laid the tile, again check the site. By removing ledges and irregularities, cover all seams with a dry cement-sand mixture, sweep away the excess and hose with a spray humidified mixture into the gaps.

Paving requires maintenance. It should be cleaned regularly, from time to time to wash. And in the winter to clean snow from the tracks, you cannot use a metal tool to the surface of the tiles. It is not necessary to break the tile lacquers, paints and other chemicals. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: proftula.ru/articles/187/30124/