697

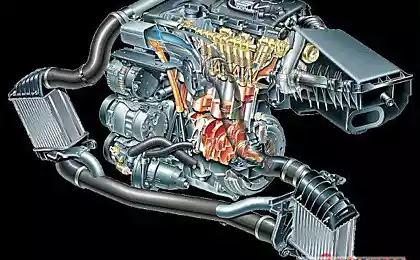

As I analyzed the collected-diesel engine

Recently, Yap something very intensified technical subjects ... it is still commendable, look, young people begin to understand that the bread does not tear off breadfruit ...

I want to light the 17 pictures ... this is my first been hell knows what the account office, however, also please do not swear, if you get a shoal.

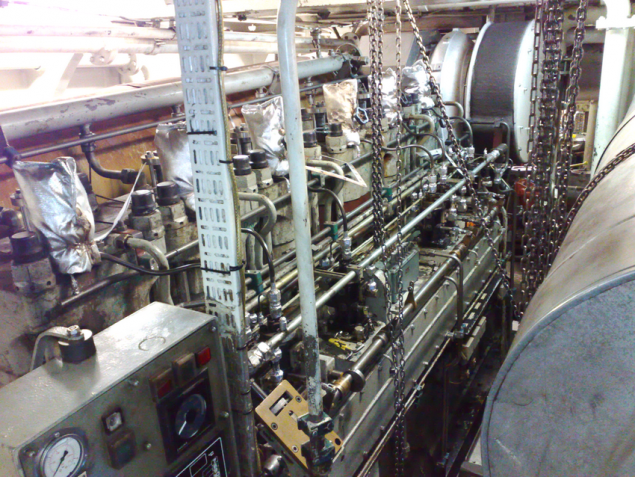

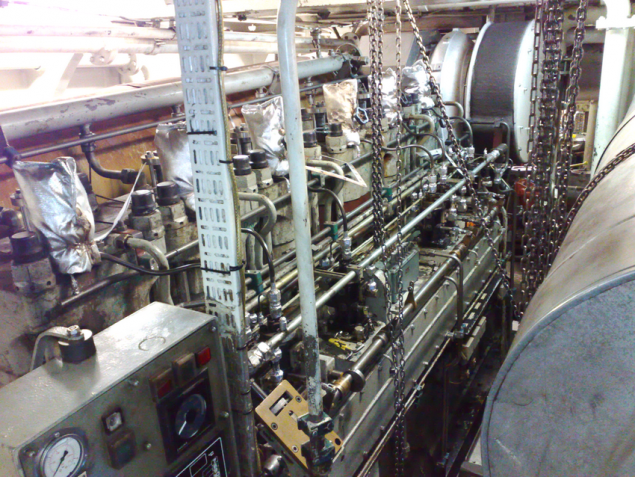

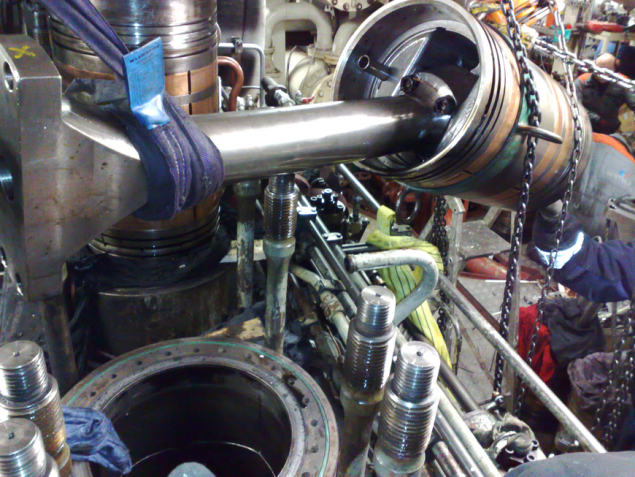

So one sunny but cold day we arrived on one of the ships, in order to proceed with the repair - it was necessary to replace the gasket on the two cylinder liners of one of the four main diesel engine of the boat. The picture can be seen a fragment and our working machine.

after going to the engine room and found there four small diesel engine, each with a capacity of about 1,000 drugs. These two-stroke engines, the device simple.

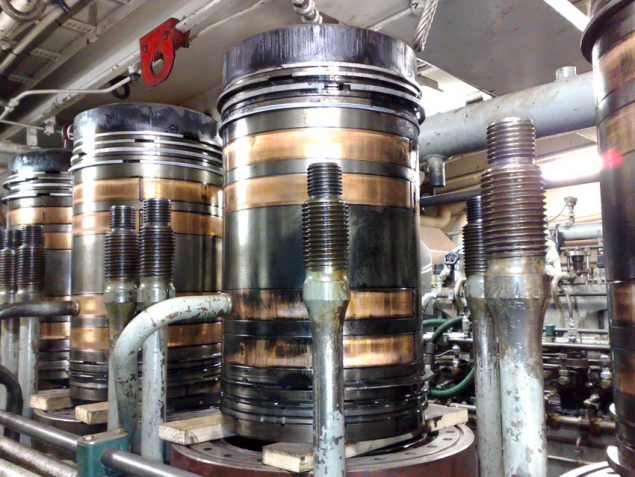

In principle, everything is arranged in the same way as in automobile engines ... well, except slightly larger in size. It makes some difference from conventional engines. After removing all pipes of diesel fuel injectors and other trifles were removed cylinder head ... That's kind of without these heads. Pay attention to the studs - they are two different thread about it ... more ...

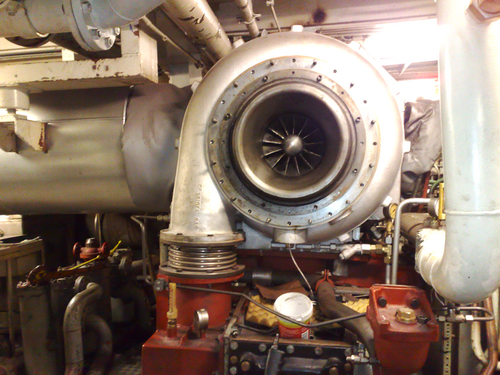

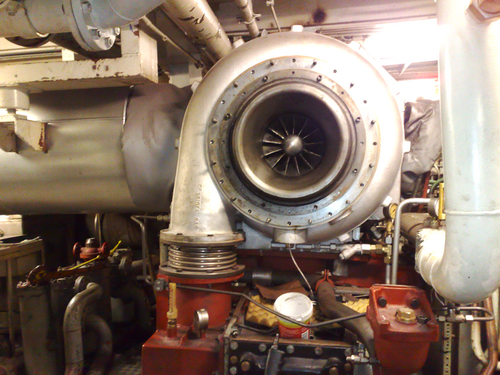

Oh yeah, I almost forgot ... all the ship's diesel engines are equipped with turbo charge air. That's how it looks at this engine. The diameter of it somewhere and a half meters.

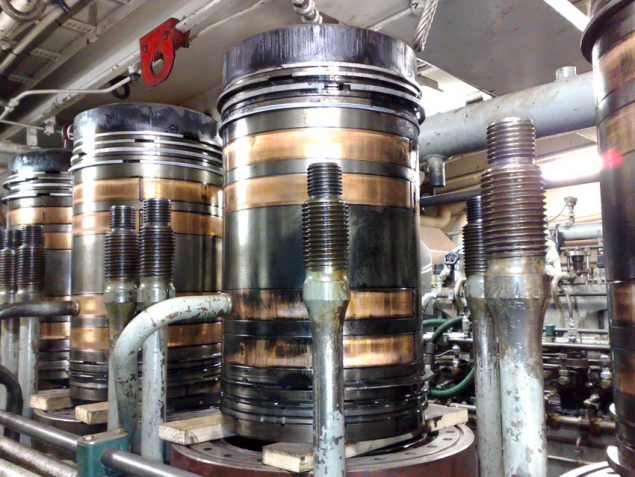

head combustion chambers ... that they are handsome, lie on the floor. Dimensions in square section where the meter on ... In general there are 6 cylinders, but for some reason the pictures 5

heavy stsuki ... Generally ships awful lot of things heavy iron and iron ... sometimes takes somneniya- as he swims ???

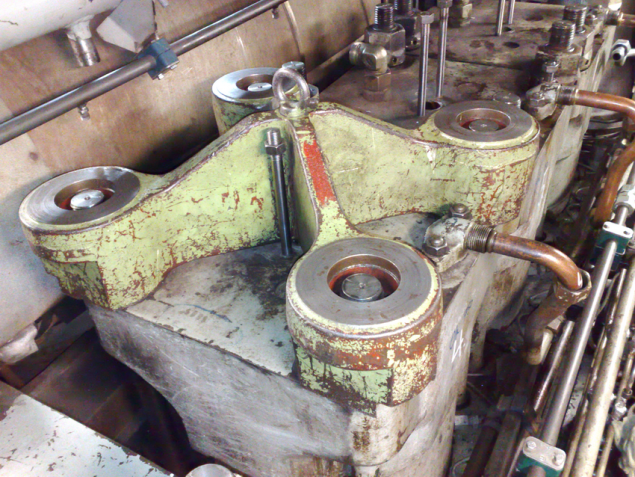

briefly about the features of dismantling heads: These heads were tightened nuts on 80. Clear pepper, loosen the key here in my arms forces would not be enough. For this are some devices. That view of the head is still not removed, but ready-to-install device:

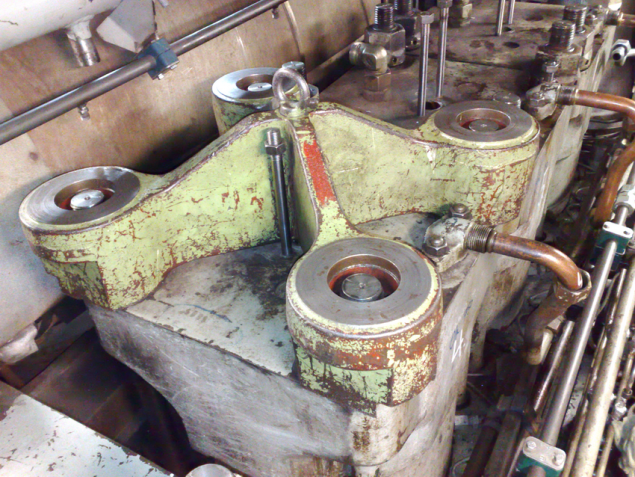

superimposed on top of the head is such kraboobraznaya Mandula ...

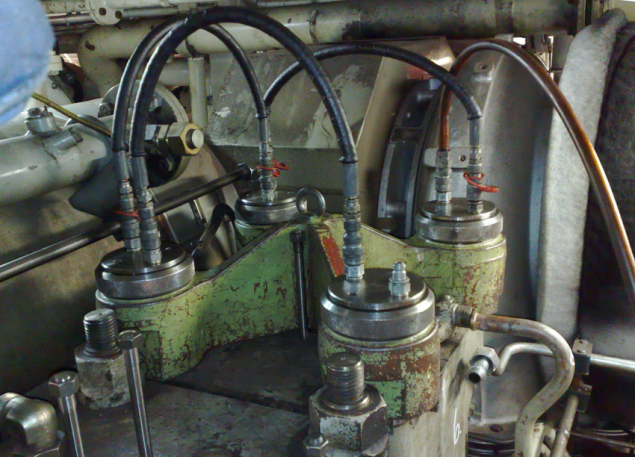

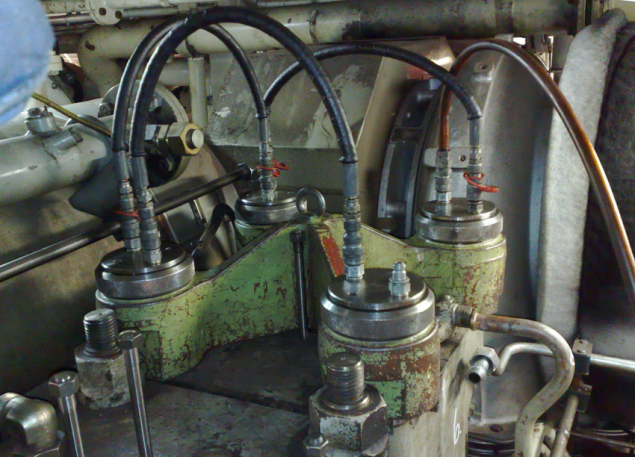

I was there first mentioned about additional thread on the heels ... and so, on this thread are wound hydraulic screw jacks ... with their help overcome the force that keeps the nut. By applying pressure to the jacks, presses the heads to the cylinders, and then the nuts unscrewed bare hands.

Rams in series connected high-pressure hose to the hand pump.

By the way, I'm a bit risky, clutching the connection of high pressure hoses hands ... Later, in special courses showed us photos of dissected hands streams of oil that burst hose connections ... all the same pressure of 750 atmospheres ... no joke ... Personally, he was cutting wood with water at 200 atmsosfer ...

pump is the most common ... nothing special ... The most important thing to monitor the pressure gauge - pressure jacks should be (according to the documentation) exactly 750 atmospheres.

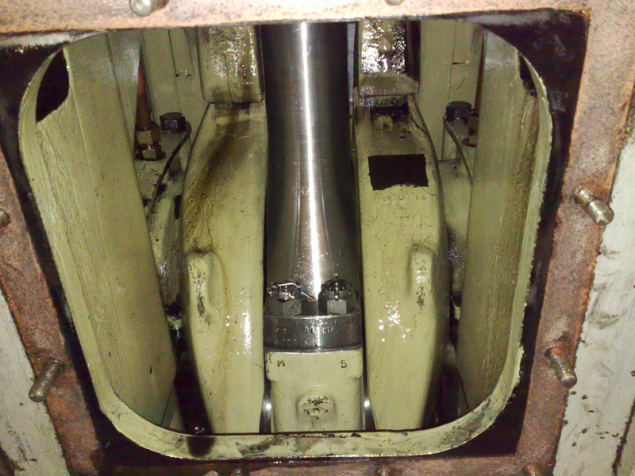

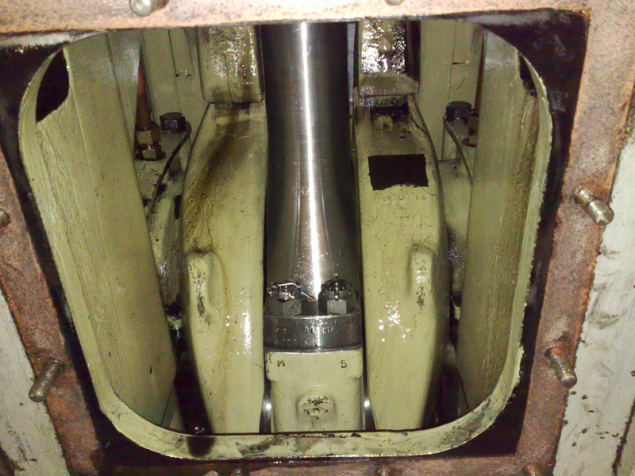

at the bottom of the motor have hatches, closing windows that open access to the mounting rods to the crankshaft.

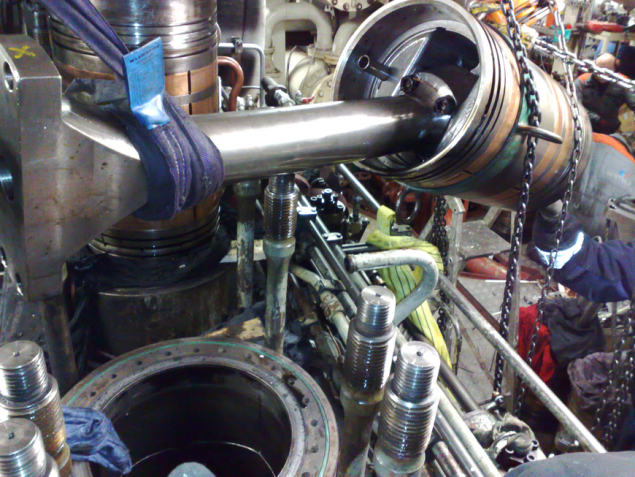

after being disconnected from the crankshaft connecting rods, they raise the top neatly and carefully studied by measuring the clearance and condition of the sealing rings. In the picture you can see that there is a ring at the top and bottom. And the copper insert.

These pistons are not made of aluminum, in the car, and iron ... heavy with rods under the 200 kilogram weight ... of course, it had to take a crap and use all winches and hoists. And of course with the help of some kind of a mother ... (and not only in Russian)

Source:

I want to light the 17 pictures ... this is my first been hell knows what the account office, however, also please do not swear, if you get a shoal.

So one sunny but cold day we arrived on one of the ships, in order to proceed with the repair - it was necessary to replace the gasket on the two cylinder liners of one of the four main diesel engine of the boat. The picture can be seen a fragment and our working machine.

after going to the engine room and found there four small diesel engine, each with a capacity of about 1,000 drugs. These two-stroke engines, the device simple.

In principle, everything is arranged in the same way as in automobile engines ... well, except slightly larger in size. It makes some difference from conventional engines. After removing all pipes of diesel fuel injectors and other trifles were removed cylinder head ... That's kind of without these heads. Pay attention to the studs - they are two different thread about it ... more ...

Oh yeah, I almost forgot ... all the ship's diesel engines are equipped with turbo charge air. That's how it looks at this engine. The diameter of it somewhere and a half meters.

head combustion chambers ... that they are handsome, lie on the floor. Dimensions in square section where the meter on ... In general there are 6 cylinders, but for some reason the pictures 5

heavy stsuki ... Generally ships awful lot of things heavy iron and iron ... sometimes takes somneniya- as he swims ???

briefly about the features of dismantling heads: These heads were tightened nuts on 80. Clear pepper, loosen the key here in my arms forces would not be enough. For this are some devices. That view of the head is still not removed, but ready-to-install device:

superimposed on top of the head is such kraboobraznaya Mandula ...

I was there first mentioned about additional thread on the heels ... and so, on this thread are wound hydraulic screw jacks ... with their help overcome the force that keeps the nut. By applying pressure to the jacks, presses the heads to the cylinders, and then the nuts unscrewed bare hands.

Rams in series connected high-pressure hose to the hand pump.

By the way, I'm a bit risky, clutching the connection of high pressure hoses hands ... Later, in special courses showed us photos of dissected hands streams of oil that burst hose connections ... all the same pressure of 750 atmospheres ... no joke ... Personally, he was cutting wood with water at 200 atmsosfer ...

pump is the most common ... nothing special ... The most important thing to monitor the pressure gauge - pressure jacks should be (according to the documentation) exactly 750 atmospheres.

at the bottom of the motor have hatches, closing windows that open access to the mounting rods to the crankshaft.

after being disconnected from the crankshaft connecting rods, they raise the top neatly and carefully studied by measuring the clearance and condition of the sealing rings. In the picture you can see that there is a ring at the top and bottom. And the copper insert.

These pistons are not made of aluminum, in the car, and iron ... heavy with rods under the 200 kilogram weight ... of course, it had to take a crap and use all winches and hoists. And of course with the help of some kind of a mother ... (and not only in Russian)

Source:

"Look at the world through the eyes of children" - a unique advertising campaign

Brought the sand ...