544

Production of leather

Writes Alexey Zabolotnov

Manufacture of leather in Morocco takes place in hellish conditions: under the burning sun the workers manually processed leather, standing knee-deep in water and adding lime dog \ bird droppings. In contrast to the treatment plant is only natural dyes. None of the tour operator does not offer you these tours, so go watch the production of their own and are usually tend to do all go to Fez. But we decided to look for production in Marrakech.

All production is by hand and under the scorching sun, while there is such a hell of a stink (why - will learn later). First, we wandered through the narrow streets of the medina (old city) in search of these same factories. As a result, we found the guy who offered to show us the production. He even called himself the owner of the factory (but it seems just slukavil).

On the road we come across the carts, which carry the factory skins (usually cow, sheep or goat):

The received skin goes through the stage of sorting:

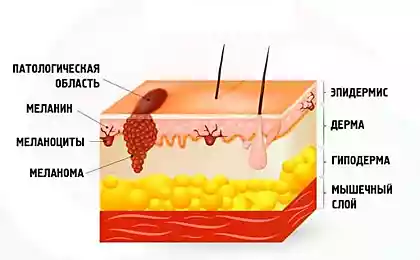

Next skin passes the primary processing - it is soaked in a bath with a solution of lime and water, and the skin was soft here add dog, chicken or pigeon droppings. That is why there is a hell of a smell (and of course skin itself also adds flavor)

On the way to the factory, we bought a small bunch of mint that is not to suffocate. But the work looks like the smell quite terrible:

Here is one of the shops of leather factory in Marrakech:

In this solution, the skin soaked from several days to several weeks. If necessary, can soak a few times:

The factory does not use any chemicals, all natural

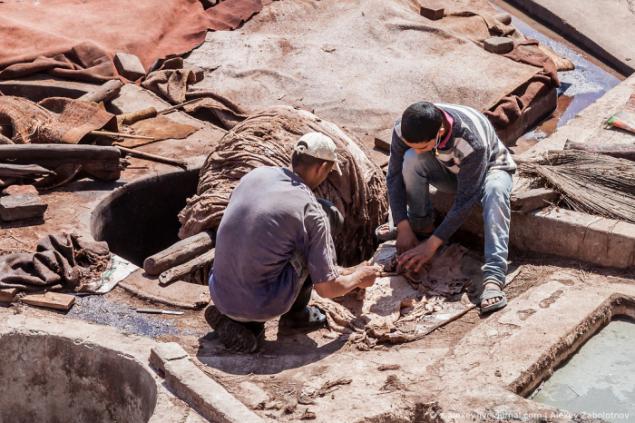

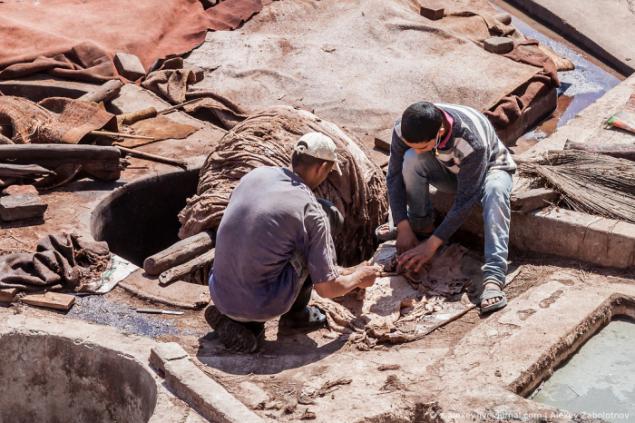

After soaking the skin is sent to the apprentice, is manually cleaned from the remnants of wool:

And then the skin soaked in clean water (can add lime), and dried:

Leather industry in Marrakech

There are also a number of workshops in which sew bags, sneakers and other things here and sell them

In the next step the skin is painted in the color you want. For this purpose the skin again placed in the bath with the desired dye, and held there for several weeks. That color was uniformly kneaded it periodically:

Again, no chemical dyes, all only natural. For example, to use saffron yellow and red to - paprika.

This picture is from the other factories, it is natural dyes for dyeing of fabrics:

After watching the first workshop, we have got to the store and trying to sell something. We immediately began to say that it is not interesting. But then the seller said that we did not let on. As a result, we still have persuaded him, and we looked and made photos, which were higher. And this is another common plan:

Well, finished leather goes to workshops where sew from her bag or ottoman or Grandma (Moroccan slippers)

And here is the finished product, Moroccan Grandma:

©

Manufacture of leather in Morocco takes place in hellish conditions: under the burning sun the workers manually processed leather, standing knee-deep in water and adding lime dog \ bird droppings. In contrast to the treatment plant is only natural dyes. None of the tour operator does not offer you these tours, so go watch the production of their own and are usually tend to do all go to Fez. But we decided to look for production in Marrakech.

All production is by hand and under the scorching sun, while there is such a hell of a stink (why - will learn later). First, we wandered through the narrow streets of the medina (old city) in search of these same factories. As a result, we found the guy who offered to show us the production. He even called himself the owner of the factory (but it seems just slukavil).

On the road we come across the carts, which carry the factory skins (usually cow, sheep or goat):

The received skin goes through the stage of sorting:

Next skin passes the primary processing - it is soaked in a bath with a solution of lime and water, and the skin was soft here add dog, chicken or pigeon droppings. That is why there is a hell of a smell (and of course skin itself also adds flavor)

On the way to the factory, we bought a small bunch of mint that is not to suffocate. But the work looks like the smell quite terrible:

Here is one of the shops of leather factory in Marrakech:

In this solution, the skin soaked from several days to several weeks. If necessary, can soak a few times:

The factory does not use any chemicals, all natural

After soaking the skin is sent to the apprentice, is manually cleaned from the remnants of wool:

And then the skin soaked in clean water (can add lime), and dried:

Leather industry in Marrakech

There are also a number of workshops in which sew bags, sneakers and other things here and sell them

In the next step the skin is painted in the color you want. For this purpose the skin again placed in the bath with the desired dye, and held there for several weeks. That color was uniformly kneaded it periodically:

Again, no chemical dyes, all only natural. For example, to use saffron yellow and red to - paprika.

This picture is from the other factories, it is natural dyes for dyeing of fabrics:

After watching the first workshop, we have got to the store and trying to sell something. We immediately began to say that it is not interesting. But then the seller said that we did not let on. As a result, we still have persuaded him, and we looked and made photos, which were higher. And this is another common plan:

Well, finished leather goes to workshops where sew from her bag or ottoman or Grandma (Moroccan slippers)

And here is the finished product, Moroccan Grandma:

©