980

Report from the factory: how do Belarusian stiralki

Text and photo will

Every six out of ten washing machines, purchased in Belarus, - domestic production. While the first "stiralku" near Minsk gathered from Italian components in 2003 alone. Screwdriver assembly ended in early 2007 - then the plant "Atlant" has produced the first-ever truly Belarusian washing machine. Correspondents Onliner.by visited today in the production of domestic home appliances, with a photo essay that represents your attention.

The structure of "Atlanta" is now one of the three major businesses: Minsk Refrigerator Plant, which produces holodilinki, factory of household appliances in Shabani, engaged in production of washing machines and Baranovichi Machine-Tool Plant, which produces compressors for household refrigerators, technological complexes for processing of plastics, conveyor systems and kettles.

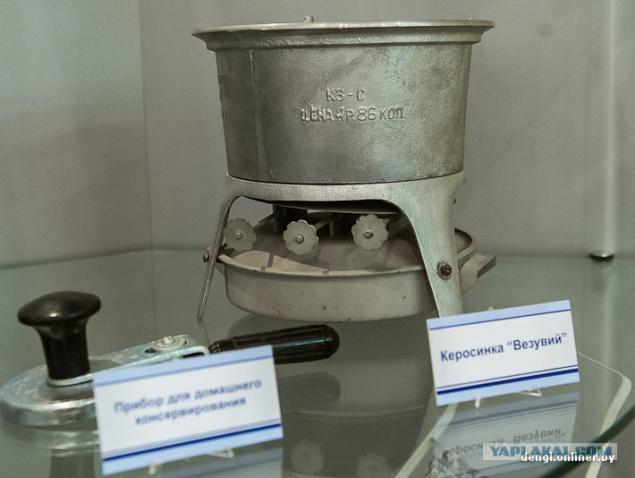

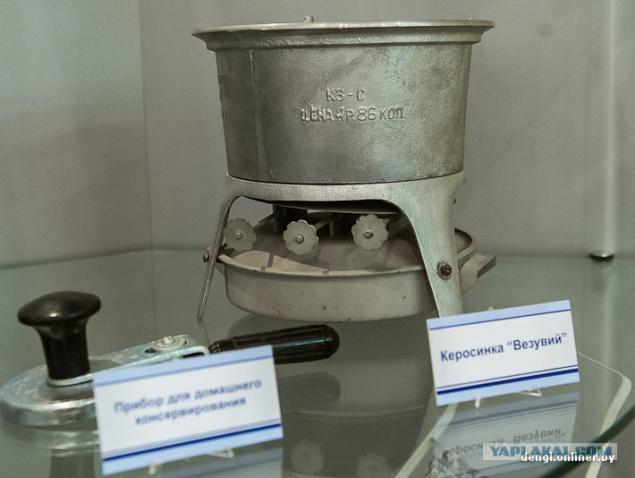

In the 50s of the last century the history of the company, whose products are presented in the homes of millions of consumers, began with a very unpretentious instrument: children kolyasochek, seaming machines and stoves. Now samples of these products are presented in the museum business.

After half a century been here it's different. On the Prospect Winners produce nearly 1, 5 million refrigerators, and Shabani - 310 thousand. Washing machines.

text a lot - will reduce and choose

Tour of the manufacture of the representatives of "Atlanta" started with a test center. Through it pass all models of washing machines that later fall on the conveyor. They checked up to 6 months, performing at the same time about 2,500 washing cycles. "Belarus - the only country in the CIS, which has developed its own standard for washing machines. It is similar to European standards, "- said Vladimir Rozhkov, deputy head of the test center.

Who washing machines "Atlas" held about 60% of the Belarusian market. To improve the position on October 1, the Belarusian company is going to start production of new models for yourself - loading washing machines with 7 kg Energy efficiency class "A ++».

According to Vladimir Rozhkov, a modern washing machine is designed around 2500 washes during the warranty period - approximately 250 washes per year. "However, so intense, according to our research, the technique of using only 12-14% of households," - said the expert.

He also believes that the best use of the small city "stiralki": "I have a home machine for 3, 5 kg of laundry. This is convenient for frequent washing. "

...

Drums future washing machines are manufactured from stainless steel. She comes to the company from Russia in rolls.

...

At the line where the body is made from a metal washer, as little people. "We are committed to maximum automation. People can come to work with a different mood, different ideas, and the car always do everything well ", - said the head of personnel at the plant Bruenkov Michael Shabanov.

...

...

After that, the body is primed. Complete filling a bath (in which the application of the preliminary ground layer) is 35 cubic meters. m and cost about $ 1 million. The solution inside the tank by means of powerful pumps are always kept in motion.

...

...

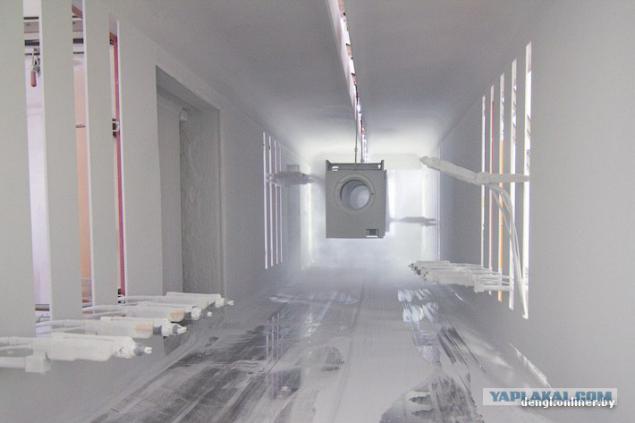

Already on the prepared surface is applied powder coating. Now all the washing machines white, but in the future in Minsk also planned to produce black and "stiralki" color "metallic". "The main thing - customer demand", - says Mikhail Bruenkov.

...

But the washing machines and dryers, which are popular in the US, in the capital will see soon. "You need to completely change the hardware, even to build a new plant. Who from us is buying? "- Said the representatives of" Atlanta ».

The housing of the washing machine after dyeing enters the furnace, and then supplied to the assembly line where it joins the "stuffing."

...

...

Before packing each washing machine and additional testing. "Many buyers complain then, they say, bought a new car, and inside - residual moisture. But it is, on the contrary, it indicates that it was tested. In addition, after this test has selectively 3% of the cars are in the test center a complete cycle, "- said Mikhail Bruenkov.

Now domestic "stiralka" used motor made in Baranovichi. "We used to buy engines from Bosch and Siemens, but now on a new line, acquired from Bosch, can provide themselves accessories. Some products will also be sold to Bosch plant in St. Petersburg ", - said at a press conference the CEO of" Atlanta "Victor Shumilo.

Head of the company is confident that with time, the Belarusians will go on appliances with high energy efficiency. But now it is not profitable, as electricity in the country inexpensive. "The state currently subsidizes 80% of the cost of electricity," - said Shumilo.

As for the price of the washing machine, then on the "Atlanta" notice - Belarusian equipment is quite competitive. "Over the past year we have reduced the cost of the washing machine at 20 euros - this is a very good indicator", - told to "Atlanta". The average salary in August there was 5, 15 million rubles. But the CEO of the company did not disclose the level of their income. "You will become the director of" Atlanta "- Learn - said Victor Shumilo. - According to our internal rules of the salary information is private. My salary corresponds to market conditions ».

PS For this generation, and all forward sleepers from belorusonenavistnikov. For I bought - and then sold all the text from the source.

PPS need to love the motherland, that is. While sometimes it's very hard

Hardly the most important photos are not forgotten!

Source:

Every six out of ten washing machines, purchased in Belarus, - domestic production. While the first "stiralku" near Minsk gathered from Italian components in 2003 alone. Screwdriver assembly ended in early 2007 - then the plant "Atlant" has produced the first-ever truly Belarusian washing machine. Correspondents Onliner.by visited today in the production of domestic home appliances, with a photo essay that represents your attention.

The structure of "Atlanta" is now one of the three major businesses: Minsk Refrigerator Plant, which produces holodilinki, factory of household appliances in Shabani, engaged in production of washing machines and Baranovichi Machine-Tool Plant, which produces compressors for household refrigerators, technological complexes for processing of plastics, conveyor systems and kettles.

In the 50s of the last century the history of the company, whose products are presented in the homes of millions of consumers, began with a very unpretentious instrument: children kolyasochek, seaming machines and stoves. Now samples of these products are presented in the museum business.

After half a century been here it's different. On the Prospect Winners produce nearly 1, 5 million refrigerators, and Shabani - 310 thousand. Washing machines.

text a lot - will reduce and choose

Tour of the manufacture of the representatives of "Atlanta" started with a test center. Through it pass all models of washing machines that later fall on the conveyor. They checked up to 6 months, performing at the same time about 2,500 washing cycles. "Belarus - the only country in the CIS, which has developed its own standard for washing machines. It is similar to European standards, "- said Vladimir Rozhkov, deputy head of the test center.

Who washing machines "Atlas" held about 60% of the Belarusian market. To improve the position on October 1, the Belarusian company is going to start production of new models for yourself - loading washing machines with 7 kg Energy efficiency class "A ++».

According to Vladimir Rozhkov, a modern washing machine is designed around 2500 washes during the warranty period - approximately 250 washes per year. "However, so intense, according to our research, the technique of using only 12-14% of households," - said the expert.

He also believes that the best use of the small city "stiralki": "I have a home machine for 3, 5 kg of laundry. This is convenient for frequent washing. "

...

Drums future washing machines are manufactured from stainless steel. She comes to the company from Russia in rolls.

...

At the line where the body is made from a metal washer, as little people. "We are committed to maximum automation. People can come to work with a different mood, different ideas, and the car always do everything well ", - said the head of personnel at the plant Bruenkov Michael Shabanov.

...

...

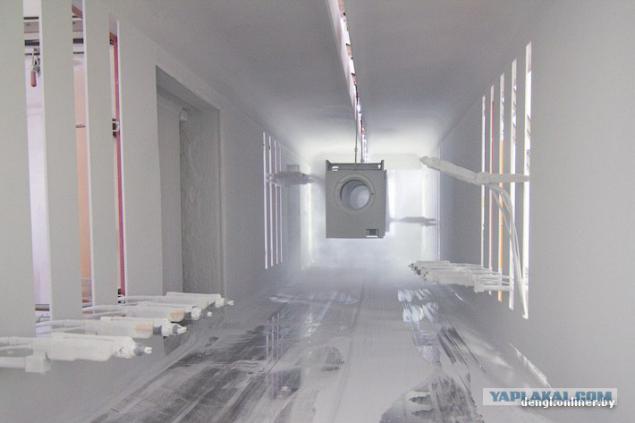

After that, the body is primed. Complete filling a bath (in which the application of the preliminary ground layer) is 35 cubic meters. m and cost about $ 1 million. The solution inside the tank by means of powerful pumps are always kept in motion.

...

...

Already on the prepared surface is applied powder coating. Now all the washing machines white, but in the future in Minsk also planned to produce black and "stiralki" color "metallic". "The main thing - customer demand", - says Mikhail Bruenkov.

...

But the washing machines and dryers, which are popular in the US, in the capital will see soon. "You need to completely change the hardware, even to build a new plant. Who from us is buying? "- Said the representatives of" Atlanta ».

The housing of the washing machine after dyeing enters the furnace, and then supplied to the assembly line where it joins the "stuffing."

...

...

Before packing each washing machine and additional testing. "Many buyers complain then, they say, bought a new car, and inside - residual moisture. But it is, on the contrary, it indicates that it was tested. In addition, after this test has selectively 3% of the cars are in the test center a complete cycle, "- said Mikhail Bruenkov.

Now domestic "stiralka" used motor made in Baranovichi. "We used to buy engines from Bosch and Siemens, but now on a new line, acquired from Bosch, can provide themselves accessories. Some products will also be sold to Bosch plant in St. Petersburg ", - said at a press conference the CEO of" Atlanta "Victor Shumilo.

Head of the company is confident that with time, the Belarusians will go on appliances with high energy efficiency. But now it is not profitable, as electricity in the country inexpensive. "The state currently subsidizes 80% of the cost of electricity," - said Shumilo.

As for the price of the washing machine, then on the "Atlanta" notice - Belarusian equipment is quite competitive. "Over the past year we have reduced the cost of the washing machine at 20 euros - this is a very good indicator", - told to "Atlanta". The average salary in August there was 5, 15 million rubles. But the CEO of the company did not disclose the level of their income. "You will become the director of" Atlanta "- Learn - said Victor Shumilo. - According to our internal rules of the salary information is private. My salary corresponds to market conditions ».

PS For this generation, and all forward sleepers from belorusonenavistnikov. For I bought - and then sold all the text from the source.

PPS need to love the motherland, that is. While sometimes it's very hard

Hardly the most important photos are not forgotten!

Source: