454

Mini pickaxe

Kirk (or more precisely - by Kyle) - Tool undeservedly forgotten, but fortunately for most - rarely found in everyday life.

Author sayings "against breakage no reception!" He seems to have lived in a fantasy world of their fantasies, which never set foot man armed with a pickaxe.

The strong arms attached to the body with a bad head, the subject has no equal among the hand-percussion instruments!

For the production of the current model of picks on a scale of 1 to 12 it was used a segment of the metal strip 8h50mm as well as a handle - a sliver of alder lining.

Then you can see 20 photos of the manufacturing process here

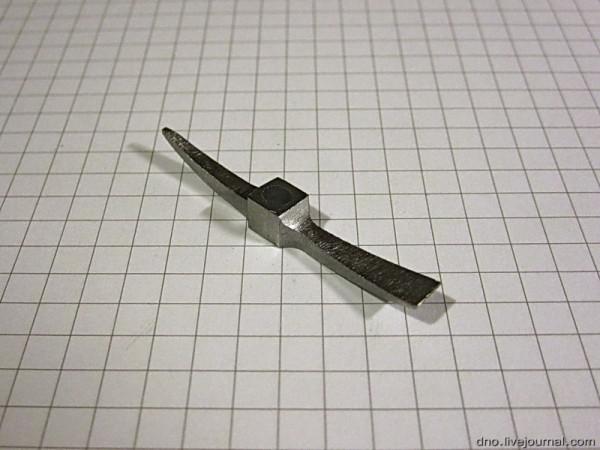

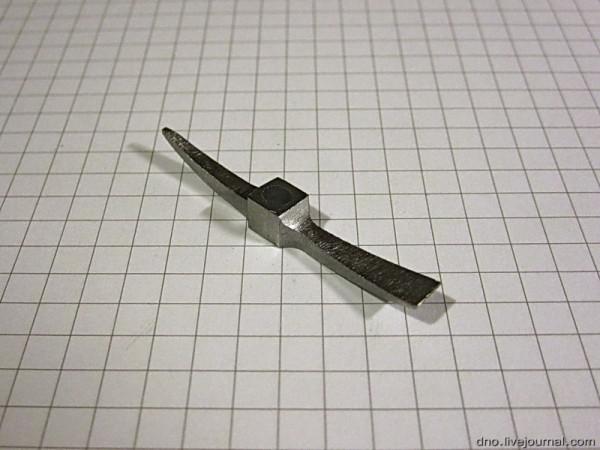

2. Materials used.

3. The hole is drilled under the handle of the future and saw off the required width of the workpiece. In this case, it is suitable for cutting ordinary hacksaw.

4. round file make cross-deepening hole near the handle.

5.

6. Round needle files of the hole, giving it an oval shape and slightly rastachivaya outside. This is to ensure that the tool is inserted from above into the handle having a thickening at the end, firmly hold and prevent unauthorized picks in flights separately from the hilt.

7. workpiece file.

8. saw off excess hacksaw.

9.

10. And here we are, you guessed it ... keep the workpiece with a file ...

11.

12.

13.

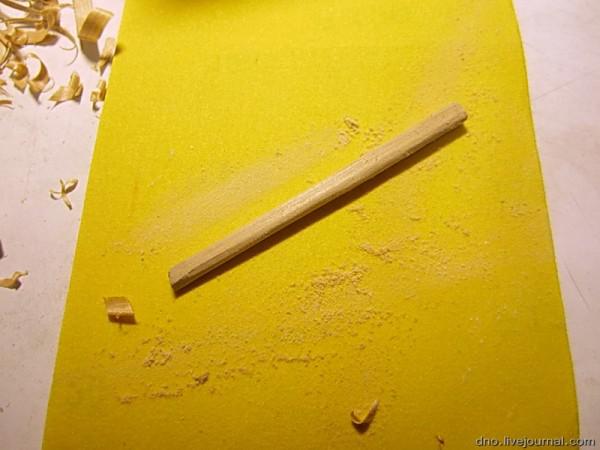

14. The handle is made of any hardwood with a homogeneous structure. In this case, I used alder.

15. Excess plane down the knife.

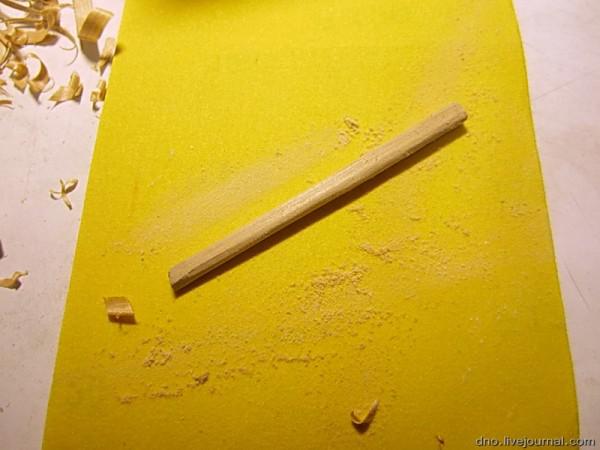

16. skins of sandpaper.

17. The instrument must be mounted on the handle, or more precisely - trying to drive a stick into the tool.

18.

19.

20.

Source:

Author sayings "against breakage no reception!" He seems to have lived in a fantasy world of their fantasies, which never set foot man armed with a pickaxe.

The strong arms attached to the body with a bad head, the subject has no equal among the hand-percussion instruments!

For the production of the current model of picks on a scale of 1 to 12 it was used a segment of the metal strip 8h50mm as well as a handle - a sliver of alder lining.

Then you can see 20 photos of the manufacturing process here

2. Materials used.

3. The hole is drilled under the handle of the future and saw off the required width of the workpiece. In this case, it is suitable for cutting ordinary hacksaw.

4. round file make cross-deepening hole near the handle.

5.

6. Round needle files of the hole, giving it an oval shape and slightly rastachivaya outside. This is to ensure that the tool is inserted from above into the handle having a thickening at the end, firmly hold and prevent unauthorized picks in flights separately from the hilt.

7. workpiece file.

8. saw off excess hacksaw.

9.

10. And here we are, you guessed it ... keep the workpiece with a file ...

11.

12.

13.

14. The handle is made of any hardwood with a homogeneous structure. In this case, I used alder.

15. Excess plane down the knife.

16. skins of sandpaper.

17. The instrument must be mounted on the handle, or more precisely - trying to drive a stick into the tool.

18.

19.

20.

Source: