755

Gasoline from the air

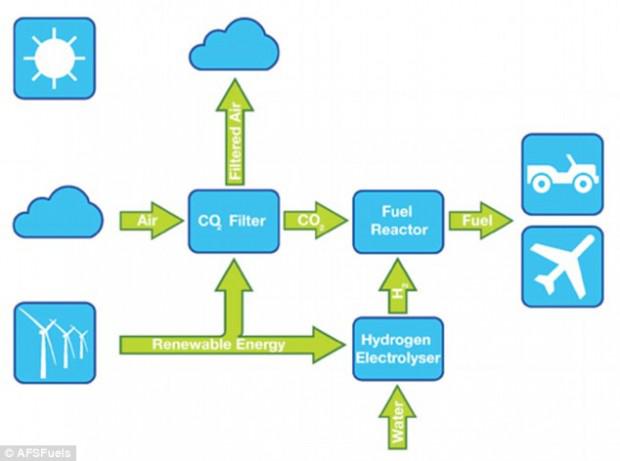

Scientists from the British company Air Fuel Synthesis learned to produce synthesis gas by carbon dioxide and water vapors. Representatives of the company say that in August they managed to create five liters of gasoline on a miniature reprocessing komplekse.

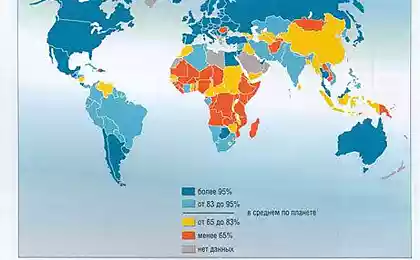

The Air Fuel Synthesis believe that their development can become a solution to the growing energy crisis worldwide. The production of one ton of gasoline on the new technology costs about 400 pounds (644 US dollars). Workflow company comprises mixing air with sodium hydroxide. The resulting action of sodium hydrogen carbonate is electrolyzed, which allows you to create natural carbon gaz.

Subsequently, it is mixed with hydrogen extracted from the water that forms the hydrocarbon mixture. Conditions of the chemical reaction is determined what type of fuel is obtained. According to the Air Fuel Synthesis, after mixing with the fuel additives, fuel tank can be refilled. Currently, employees of the company use the electricity from the network, but later the firm hopes to be fully autonomous from its own renewable reserves goryuchego.

The Air Fuel Synthesis expect two years to build a full-fledged processing complex, which is able to produce a ton of gasoline a day, and even after 15 years, representatives of the company planning to produce synthetic fuels on a commercial scale.

Source: motor.ru/news/2012/10/19/gasoline/