1249

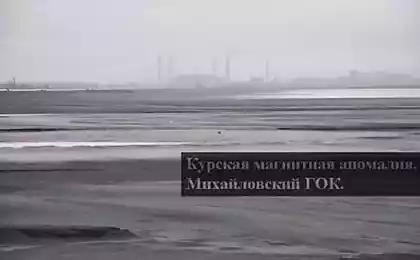

Mining and overburden complex

I suggest you to admire its majesty and grandeur of KU-800. This rotary machine of - only a part of a large and complex system of mining and overburden complex. In addition to the KU-800, it includes conveyor lines, reloading components and spreader. Task excavator - remove loose deposits of rock deposits.

Each of the nodes GVK deserves attention, but still wheel excavator - its main attraction. The height of the excavator 54 meters, weight - 3000 350 tonnes. This compares with a weight of 100 subway cars. From this amount of metal it can be done 70 T-90 tanks.

Excavator rests on the turntable and moves with "Ski", which are driven by hydraulic cylinders.

To operate the excavator necessary voltage of 35 thousand volts.

Mechanic Ivan Tolmachev of the people who participated in the start-KU-800. More than 40 years ago, in 1972, immediately after Gubkin mountain college, Ivan Dmitrievich took assistant engineer bucket wheel excavator. That's really when I had to run on a young specialist stair galleries! The fact that the electric part of the excavator proved far from perfect, so more than one hundred steps had to be overcome until you find the cause of failure of a node. Plus, the documents translated from Czech incomplete. To get to the circuit over the papers had to sit out at night, because in the morning it was necessary to find a way to eliminate a particular fault.

The secret of longevity KU-800 in its particular mode of operation. The fact is that, except for scheduled maintenance in the operating season, in the winter the entire complex stands on major repairs and perform rearrangements of conveyor lines. Three months GVK prepare for the new season. During this time, time to put in order all components and assemblies. For example, last winter changed the ball joint, which rotates the rotary portion of the excavator. Can you imagine a bearing, in which each of the two hundred and fifty "balls" weighs 58 kilograms?

On his excavator Alex Martianov, machinists foreman GVK said with love, as an animate object. He says that this has nothing to be ashamed of: each of his crew also applies to his car. Moreover, as a living are beginning to respond and experts of the Czech factory, supervising major repairs excavator.

Breed KU-800 cuts a ten buckets attached to a rotary wheel. Wheel diameter - 11 meters, and it is rotated with a speed of 7 rpm. Operator Station hangs near the rotary wheel at a height of 20 meters.

Alex Martianov in a cabin with a view of the rotor excavator. Rotating the wheel three-storey impressive. In general, by traveling through the galleries KU-800 is breathtaking.

- You have the impression, probably already a bit dim?

- Yes, there is, of course. After all, since 1971, I have been working here.

- So after all those years of excavator not yet been?

- There was a platform on which it only began to mount. He walked here nodes, about three years collecting his chief-fitters Czechs.

- At the time this technique was unprecedented?

- Yes, this is the fourth car, coming off the assembly line of the Czech manufacturer. Newsboys us then downright attacked. Even in the journal "Science and Life" wrote about our excavator.

- Could you then suggest that in 30 years will still work on it?

- Hard to say. But in fact, this is a very smart machine. In the sense that it has a good protection, good automation, good controllability. It does not allow you to zalihachil immediately work to protect and stop the engine.

- How can scorcher here, it's not a "passenger car", for example?

- Do not "passenger car", but cornering is important not to "ruin" the rotor, if the deep stope entrance. Of the ten positions to choose one - right: rotate, lift, rotary extension boom ...

- How do you manage them? Are there any secrets? That will, for example, the new man, how many months it will be possible to put here in this chair?

- It's not months, it's years. Learning to work in the cabin, crash, walk - this one, but the car feel - quite another. Because the distance from me to the driver of the loading boom of 170 meters, and we need to hear and see each other. I do not know what's probably back feel. There are, of course, and a speakerphone. I hear all five drivers. And I hear them. You also need to know the electrical device of this enormous machine. Who mastered quickly, and who only ten years later became a machinist.

The narrow iron stairs seats with movable stages entangle excavator as forest paths. Endless River excavator wires penetrate through and through.

The design of KU-800 and now amazes engineering solutions. First of all, the optimal calculation of bearing units and parts. Suffice to say, excavators, similar in performance to the Czech KU-800, have a much larger size and weight, they are one and a half times heavier.

Only at the top of the excavator, forty meters above the ground, you feel its true dimensions. It seems that the ladder galleries can be lost, and after all these intricacies of metal and cable communications there are still workers and the engine rooms, a hall with electrical equipment, switchgear bays hydraulic units pacing, turning the device lifting and extension rotary boom cranes, conveyors.

With all the metal and energy excavator works its crew of 6 people.

Hanging rooms and electrical switchgear counterbalance arm.

- Of course, I understand that it is walking excavator. But until now, I can not imagine how such a "large object" can actually walk?

- It is very well connected, well deployed. Step two and a half meters is just a minute and a half. That's handy remote control steps: skiing, base, stop, turn the excavator. A week later, we are preparing to change the location, go in the opposite direction, where the pipeline is built.

On KU-800 has several cranes 35 ton on the boom, two mounting truck 15 tons and two Jib crane.

Chalk and clay piped to the spreader.

. The driver of the loading boom.

With the loading boom breed goes on a 7-kilometer pipeline to the other side of the cut.

- There are people who say that the Rotary Complex ineffective. What would you tell them?

- I hear it for 40 years. There have been attempts to put here a simple excavator, which, according to many, is working effectively. But I've seen how it falls and drowning. And with the KU-800 nothing of the sort will happen. It will go. East aboard the most watered, but we have quite successfully worked through this slaughter.

- But, in spite of everything, aging machinery, repair is getting increasingly difficult. What you pay attention?

- We have every crew and engineer a fixed node. One - from the rotary wheel to the rear of the conveyor, the second - the rise-extension, the third - the pacing ... For winter repairs each node try to cover. See what mechanisms send in RMZ which in a power building, and that they themselves can restore. It's plan, prepare lists of deficiencies. This year made the change bucket on a rotary wheel.

- I know, it is now not so often, but Czech specialists still come to the plant to service this machine. What do they say about it as speak?

- "You need to give your excavator the Order of Lenin" - just like the last time said about her one of the specialists of the manufacturer. All his contemporaries in Czechoslovakia crumbled long ago. And this is nothing more than the evaluation of our work.

About twenty minutes breed moves a rubber band until it is discarded spreader.

Spreader - a small copy of KU-800 except for the absence of the rotary wheel. Excavator vice versa.

There is also a driver of the loading boom. Total is working to change spreaders of 4 persons.

During the 2012 season worked out and sent to dumps more than three million cubic meters of chalk. That would be enough to stretch from Stary Oskol to Moscow road (over 600 km) width of 5 meters and a height of one meter.

These are artificial beauty makes mining and overburden complex.

- What is your answer to the Czechs at the expense Ordina Lenin?

- The answer, though still coming. They inspected the metal compounds riveted ropes. They put new engines, pumps, replaced by a pitched road and have drawn the conclusion that our excavator is able to work for another 10 years. That let in 10 years, and come. And we have to work on.

Source: chistoprudov.livejournal.com

Each of the nodes GVK deserves attention, but still wheel excavator - its main attraction. The height of the excavator 54 meters, weight - 3000 350 tonnes. This compares with a weight of 100 subway cars. From this amount of metal it can be done 70 T-90 tanks.

Excavator rests on the turntable and moves with "Ski", which are driven by hydraulic cylinders.

To operate the excavator necessary voltage of 35 thousand volts.

Mechanic Ivan Tolmachev of the people who participated in the start-KU-800. More than 40 years ago, in 1972, immediately after Gubkin mountain college, Ivan Dmitrievich took assistant engineer bucket wheel excavator. That's really when I had to run on a young specialist stair galleries! The fact that the electric part of the excavator proved far from perfect, so more than one hundred steps had to be overcome until you find the cause of failure of a node. Plus, the documents translated from Czech incomplete. To get to the circuit over the papers had to sit out at night, because in the morning it was necessary to find a way to eliminate a particular fault.

The secret of longevity KU-800 in its particular mode of operation. The fact is that, except for scheduled maintenance in the operating season, in the winter the entire complex stands on major repairs and perform rearrangements of conveyor lines. Three months GVK prepare for the new season. During this time, time to put in order all components and assemblies. For example, last winter changed the ball joint, which rotates the rotary portion of the excavator. Can you imagine a bearing, in which each of the two hundred and fifty "balls" weighs 58 kilograms?

On his excavator Alex Martianov, machinists foreman GVK said with love, as an animate object. He says that this has nothing to be ashamed of: each of his crew also applies to his car. Moreover, as a living are beginning to respond and experts of the Czech factory, supervising major repairs excavator.

Breed KU-800 cuts a ten buckets attached to a rotary wheel. Wheel diameter - 11 meters, and it is rotated with a speed of 7 rpm. Operator Station hangs near the rotary wheel at a height of 20 meters.

Alex Martianov in a cabin with a view of the rotor excavator. Rotating the wheel three-storey impressive. In general, by traveling through the galleries KU-800 is breathtaking.

- You have the impression, probably already a bit dim?

- Yes, there is, of course. After all, since 1971, I have been working here.

- So after all those years of excavator not yet been?

- There was a platform on which it only began to mount. He walked here nodes, about three years collecting his chief-fitters Czechs.

- At the time this technique was unprecedented?

- Yes, this is the fourth car, coming off the assembly line of the Czech manufacturer. Newsboys us then downright attacked. Even in the journal "Science and Life" wrote about our excavator.

- Could you then suggest that in 30 years will still work on it?

- Hard to say. But in fact, this is a very smart machine. In the sense that it has a good protection, good automation, good controllability. It does not allow you to zalihachil immediately work to protect and stop the engine.

- How can scorcher here, it's not a "passenger car", for example?

- Do not "passenger car", but cornering is important not to "ruin" the rotor, if the deep stope entrance. Of the ten positions to choose one - right: rotate, lift, rotary extension boom ...

- How do you manage them? Are there any secrets? That will, for example, the new man, how many months it will be possible to put here in this chair?

- It's not months, it's years. Learning to work in the cabin, crash, walk - this one, but the car feel - quite another. Because the distance from me to the driver of the loading boom of 170 meters, and we need to hear and see each other. I do not know what's probably back feel. There are, of course, and a speakerphone. I hear all five drivers. And I hear them. You also need to know the electrical device of this enormous machine. Who mastered quickly, and who only ten years later became a machinist.

The narrow iron stairs seats with movable stages entangle excavator as forest paths. Endless River excavator wires penetrate through and through.

The design of KU-800 and now amazes engineering solutions. First of all, the optimal calculation of bearing units and parts. Suffice to say, excavators, similar in performance to the Czech KU-800, have a much larger size and weight, they are one and a half times heavier.

Only at the top of the excavator, forty meters above the ground, you feel its true dimensions. It seems that the ladder galleries can be lost, and after all these intricacies of metal and cable communications there are still workers and the engine rooms, a hall with electrical equipment, switchgear bays hydraulic units pacing, turning the device lifting and extension rotary boom cranes, conveyors.

With all the metal and energy excavator works its crew of 6 people.

Hanging rooms and electrical switchgear counterbalance arm.

- Of course, I understand that it is walking excavator. But until now, I can not imagine how such a "large object" can actually walk?

- It is very well connected, well deployed. Step two and a half meters is just a minute and a half. That's handy remote control steps: skiing, base, stop, turn the excavator. A week later, we are preparing to change the location, go in the opposite direction, where the pipeline is built.

On KU-800 has several cranes 35 ton on the boom, two mounting truck 15 tons and two Jib crane.

Chalk and clay piped to the spreader.

. The driver of the loading boom.

With the loading boom breed goes on a 7-kilometer pipeline to the other side of the cut.

- There are people who say that the Rotary Complex ineffective. What would you tell them?

- I hear it for 40 years. There have been attempts to put here a simple excavator, which, according to many, is working effectively. But I've seen how it falls and drowning. And with the KU-800 nothing of the sort will happen. It will go. East aboard the most watered, but we have quite successfully worked through this slaughter.

- But, in spite of everything, aging machinery, repair is getting increasingly difficult. What you pay attention?

- We have every crew and engineer a fixed node. One - from the rotary wheel to the rear of the conveyor, the second - the rise-extension, the third - the pacing ... For winter repairs each node try to cover. See what mechanisms send in RMZ which in a power building, and that they themselves can restore. It's plan, prepare lists of deficiencies. This year made the change bucket on a rotary wheel.

- I know, it is now not so often, but Czech specialists still come to the plant to service this machine. What do they say about it as speak?

- "You need to give your excavator the Order of Lenin" - just like the last time said about her one of the specialists of the manufacturer. All his contemporaries in Czechoslovakia crumbled long ago. And this is nothing more than the evaluation of our work.

About twenty minutes breed moves a rubber band until it is discarded spreader.

Spreader - a small copy of KU-800 except for the absence of the rotary wheel. Excavator vice versa.

There is also a driver of the loading boom. Total is working to change spreaders of 4 persons.

During the 2012 season worked out and sent to dumps more than three million cubic meters of chalk. That would be enough to stretch from Stary Oskol to Moscow road (over 600 km) width of 5 meters and a height of one meter.

These are artificial beauty makes mining and overburden complex.

- What is your answer to the Czechs at the expense Ordina Lenin?

- The answer, though still coming. They inspected the metal compounds riveted ropes. They put new engines, pumps, replaced by a pitched road and have drawn the conclusion that our excavator is able to work for another 10 years. That let in 10 years, and come. And we have to work on.

Source: chistoprudov.livejournal.com