1125

How to extract limestone

Detailed manufacturing report from Sokol-Sitovka quarry fluxing limestone deposit, located a couple of kilometers to the northeast of Lipetsk. Under the cut large excavators, BelAZ, plant, conveyors, blast and more ...

63 Photo © Dmitry Chistoprudov

1. A little official data Pit designs of "Studenovskaya Mining Company", currently the company is part of NLMK Group is one of Russian leaders in the production of fluxing limestone used mainly in the metallurgical industry and construction.

2. The volume of production is more than 15% of fluxing limestone mined in Russia.

3. Dimensions impressive career: 1500h500 meters and depth - 50 meters. Here, you can easily build more than 10 football fields or to make a track for the Formula 1 ...

4. According to geologists, stocks of raw materials in the quarry at current capacity will be enough to at least 30 years.

5. Limestone - is widely common sedimentary rock, with the participation of living organisms in the sea basins. Once upon a time, about 350-370 million years ago BC, during the Devonian period of the Paleozoic era, Lipetsk region, as many regions of the central part of Russia, was the sea. Often rock fragments can be found fossils of ancient life in those years ...

6. The field is developed by open way. The technological process of extraction of minerals can be divided into the following main activities:

Stripping

Mining operations

Dumping and mining reclamation

Transportation work

Mineral processing

7. Stripping works.

First, using a bulldozer or loader remove the top fertile soil - humus, and stored it for subsequent reclamation of land disturbed by mining operations. This is followed by a clay layer about 20 meters, which is fulfilled by electric shovels with shovels of 8 - 10 cubic meters. By stripping is also a partial sample of substandard (substandard) of limestone, which is located directly under a layer of clay.

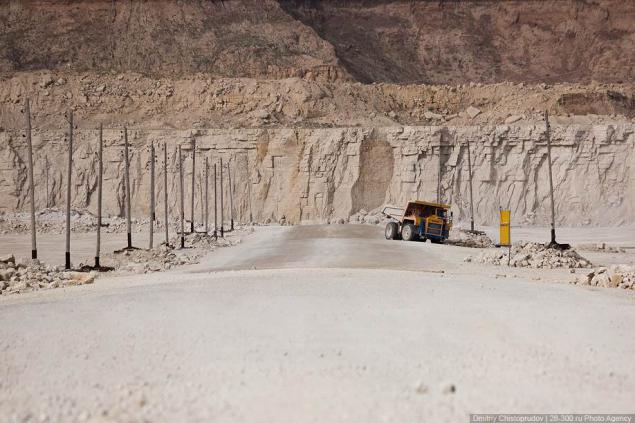

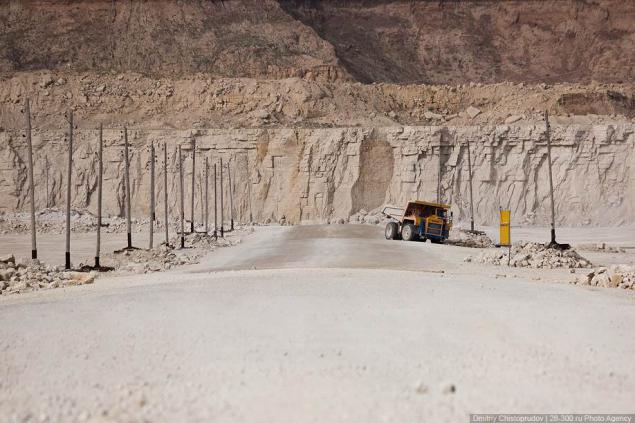

8. The photo shows a section of a good "career pie": a layer of clay, limestone and a layer of substandard flat ledge of minerals. Crumble under the ledge of limestone hill - a consequence of the explosion. That these "consequences of calling" BelAZ trucks are loaded into and transported to the factory. And all the overburden are transported into the inner blade.

9. Mining operation.

Miners have to say production, with the accent on the first syllable. Directly Limestone, preceded by blasting - the most spectacular part of the whole process.

10. A solid layer of lime, which can not scoop up a bucket excavator, it is necessary to drill, laying explosives in it and blow. For drilling used drilling rigs type RBU working on electricity.

11. Drilling rigs serious, drilled to a depth of 24 meters (7th floor) hole diameter of 16 cm. In the drilling of one well goes 50 minutes. Swirls wells extending in a line, one by one drilled 5 meters from the edge of the cliff.

12. Brave driller!

13. Explosion use industrial explosives and conversion, which is necessary for the acquisition of a whole bunch of different permits and licenses, as well as special vehicles for transportation and armed guards. Just like gunpowder in the market does not buy ...

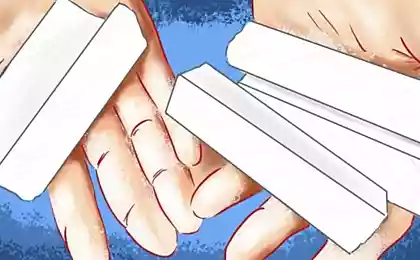

14. TNT blocks serve as a detonator.

15. On average, for a blast drilled about 30 wells, where a total of 5.6 tons of explosives laid.

16. For the connection of all wells with explosives in a single chain using detonating cord.

17. The explosion - it is very responsible! The quarry is completely being encircled in the area of the explosion put the future of security. All equipment is given to a safe distance and leave the general BelAZ quarry. Before the explosion happening all polling stations cordon on the radio and turns the situation. If all goes well, it is given permission to conduct blasting. (Post protection and transformer vault also take away).

18. Wells blasted not simultaneously, but with a delay of a few hundredths of a second, otherwise it will be an earthquake, and most of the buildings of Lipetsk povyletali glass.

19. For a sense of scale - the right of the frame is the size of the excavator 4-storey house ... Small pieces of rock can fly a distance comparable to the height of the main building of Moscow State University - 250 meters.

20. It can be seen as heavy pieces of hard rock in neat rows separated from the ledge and drop down.

21. All the explosion takes place in a few seconds and it is heard well in the city. So looks falled rock. After the smoke clears and the dust settles, Blasters will check the presence of the charges does not work, followed by excavators and BelAZ will be engaged in their work.

22. Breed loaded into BelAZ with a mechanical shovel (ie excavator) - or rather, with the help of a self-propelled steerable excavation and loading machines. This monster runs on electricity voltage of 6000 volts, in the photo you can see a high-voltage cable, which feeds the engine of the excavator. During the day, the work machine eats the same amount of energy as a normal nine-story apartment building for a week.

23. For once excavator can download the usual 10 photographers and 20 Chinese photographers.

24.

25. The weight of the bucket - 16 tons.

26. Each of the excavator works in two individuals to ensure the continuity of the production process.

27. A total of 6 large working career excavators (bucket capacity of 10 cubic meters and 8) and two smaller bucket capacity of about 5 cubic meters.

28. Sometimes the technique breaks down. For example at this excavator broke down the main gear and repairing straight in his career. The diameter of the wire ropes hanging limply - 4 cm.

29. And it - now decommissioned veteran honestly given to companies for about 40 years. Despite its age and kind of shabby, grandfather, in an emergency, it can be put into operation in the quarry.

30. dumping and mining reclamation.

At constant depth bowl career is constantly moving in the direction in which lies the limestone. On one side of the pit overburden removal takes place and the production of limestone, on the other - to develop the space is filled with overburden, gravel crushing limestone and black earth.

31.

32. crushing and concentrating plant in dump cars bring screenings produced after crushing limestone and not fit for use. Excavator passes everything on the blade, filling out space career. Then dumps falling asleep before opening a ground and top with black earth.

33. This mechanical shovel smaller - with a bucket of 5 cubes.

34. Next, carried out plowing the land and carried out biological reclamation - sowing land useful plants. A few years later reclaimed land will be reused for agricultural purposes. Earlier career starts right from the planting (right in the picture) and for 20 years has shifted in the 600 meters. Now, there is a field. In future careers may advance by 2, 7 kilometers.

35. Transport operation.

Daily on the line in a career working 12 BelAZ that provide transportation to the overburden dumps, and the limestone mined in the DOP - crushing and beneficiation plant.

36. Belazisty working around the clock in three shifts of eight hours each. During the day, BelAZ walker commits to 100, and transports the limestone mined up to 16 thousand tons. For three months the machine runs the distance from Moscow to Vladivostok.

37. Capacity of the BelAZ is 55 tons more than its own weight. BelAZ trucks with larger capacity in this career to use inappropriate for several reasons: the depth of the quarry, transport distances, production volume, and so on. It is driven by a diesel engine of the mammoth 700 l / s.

38. If the transport of BelAZ something thrown out on the road, such as a large stone, a special wheel bulldozer removes it back to the face, to the excavator.

39. In a career working actively with the dust of the road constantly poured by special Sprinkle. In winter, watering is replaced by grit sand-salt mixture.

40. To make this picture, I had to ask the driver by radio (each item is equipped with a radio station in his career) that he drove off the road watered. Permissible speed in the career of 20 km / h.

41. In a career laid 14 kilometers of technological roads constructed bulk method also has the electrification and substation to feed the excavators. The roads are excellent, for it can be easy to move by car.

42. shop for repair and maintenance of BelAZ.

43.

44. It BelAZ removed the body and the engine.

45. The extracted minerals are brought to the DOP and dumped into a hopper, in front of this truck is weighed and the weight simply by subtracting the empty weight of the load is obtained BelAZ.

46. hopper.

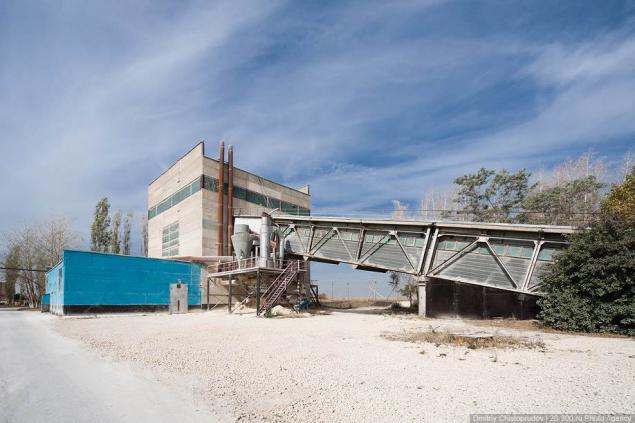

47. Processing of minerals.

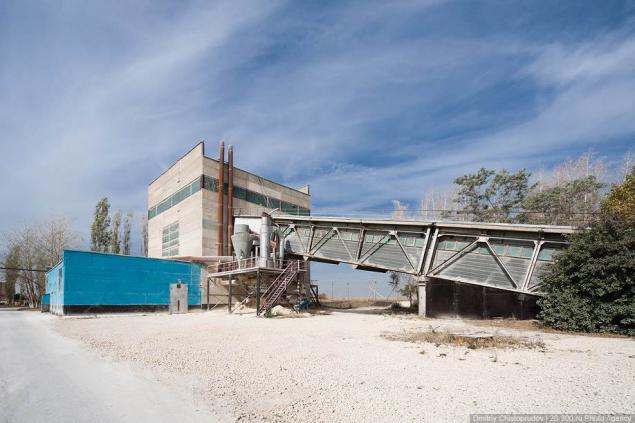

It is the first building the factory - the case of large crushing. Here in the jaw crusher comes coarse crushing of large pieces of rock. A fraction the size of a piece of 10 cm.

48. Further down the pipeline material enters the body secondary crushing.

49. As the conveyor belt is transported per day about 15 000 tons of rock.

50. Cone crusher provides secondary crushing.

51. Dodgy system of vibrating screens. In confined production devices separated into fractions (size stones) and distributed on the conveyor.

52. The shop is easy to fit a normal five-story building ...

53. Most small limestone - screenings up to 1 cm are sent to unloading in dump cars for further transport to the dump his career.

54. The case of sorting and loading. Here comes the final product, which is loaded in the w / d cars. The main consumer products - Novolipetsk Steel.

55.

56. In one car included 69 tons of crushed stone.

57.

58. Next comes loaded into trucks.

59. The work in the quarry does not stop at night. For this purpose, excavators working lights.

60.

61. UFOs.

62. 55-ton BelAZ, used to work in the career of a relatively small, but in Mountain the standards and just kids. Someday I will look at the work of the 320-tonner!

63. Night quarry and factory are beautiful!

Source:

63 Photo © Dmitry Chistoprudov

1. A little official data Pit designs of "Studenovskaya Mining Company", currently the company is part of NLMK Group is one of Russian leaders in the production of fluxing limestone used mainly in the metallurgical industry and construction.

2. The volume of production is more than 15% of fluxing limestone mined in Russia.

3. Dimensions impressive career: 1500h500 meters and depth - 50 meters. Here, you can easily build more than 10 football fields or to make a track for the Formula 1 ...

4. According to geologists, stocks of raw materials in the quarry at current capacity will be enough to at least 30 years.

5. Limestone - is widely common sedimentary rock, with the participation of living organisms in the sea basins. Once upon a time, about 350-370 million years ago BC, during the Devonian period of the Paleozoic era, Lipetsk region, as many regions of the central part of Russia, was the sea. Often rock fragments can be found fossils of ancient life in those years ...

6. The field is developed by open way. The technological process of extraction of minerals can be divided into the following main activities:

Stripping

Mining operations

Dumping and mining reclamation

Transportation work

Mineral processing

7. Stripping works.

First, using a bulldozer or loader remove the top fertile soil - humus, and stored it for subsequent reclamation of land disturbed by mining operations. This is followed by a clay layer about 20 meters, which is fulfilled by electric shovels with shovels of 8 - 10 cubic meters. By stripping is also a partial sample of substandard (substandard) of limestone, which is located directly under a layer of clay.

8. The photo shows a section of a good "career pie": a layer of clay, limestone and a layer of substandard flat ledge of minerals. Crumble under the ledge of limestone hill - a consequence of the explosion. That these "consequences of calling" BelAZ trucks are loaded into and transported to the factory. And all the overburden are transported into the inner blade.

9. Mining operation.

Miners have to say production, with the accent on the first syllable. Directly Limestone, preceded by blasting - the most spectacular part of the whole process.

10. A solid layer of lime, which can not scoop up a bucket excavator, it is necessary to drill, laying explosives in it and blow. For drilling used drilling rigs type RBU working on electricity.

11. Drilling rigs serious, drilled to a depth of 24 meters (7th floor) hole diameter of 16 cm. In the drilling of one well goes 50 minutes. Swirls wells extending in a line, one by one drilled 5 meters from the edge of the cliff.

12. Brave driller!

13. Explosion use industrial explosives and conversion, which is necessary for the acquisition of a whole bunch of different permits and licenses, as well as special vehicles for transportation and armed guards. Just like gunpowder in the market does not buy ...

14. TNT blocks serve as a detonator.

15. On average, for a blast drilled about 30 wells, where a total of 5.6 tons of explosives laid.

16. For the connection of all wells with explosives in a single chain using detonating cord.

17. The explosion - it is very responsible! The quarry is completely being encircled in the area of the explosion put the future of security. All equipment is given to a safe distance and leave the general BelAZ quarry. Before the explosion happening all polling stations cordon on the radio and turns the situation. If all goes well, it is given permission to conduct blasting. (Post protection and transformer vault also take away).

18. Wells blasted not simultaneously, but with a delay of a few hundredths of a second, otherwise it will be an earthquake, and most of the buildings of Lipetsk povyletali glass.

19. For a sense of scale - the right of the frame is the size of the excavator 4-storey house ... Small pieces of rock can fly a distance comparable to the height of the main building of Moscow State University - 250 meters.

20. It can be seen as heavy pieces of hard rock in neat rows separated from the ledge and drop down.

21. All the explosion takes place in a few seconds and it is heard well in the city. So looks falled rock. After the smoke clears and the dust settles, Blasters will check the presence of the charges does not work, followed by excavators and BelAZ will be engaged in their work.

22. Breed loaded into BelAZ with a mechanical shovel (ie excavator) - or rather, with the help of a self-propelled steerable excavation and loading machines. This monster runs on electricity voltage of 6000 volts, in the photo you can see a high-voltage cable, which feeds the engine of the excavator. During the day, the work machine eats the same amount of energy as a normal nine-story apartment building for a week.

23. For once excavator can download the usual 10 photographers and 20 Chinese photographers.

24.

25. The weight of the bucket - 16 tons.

26. Each of the excavator works in two individuals to ensure the continuity of the production process.

27. A total of 6 large working career excavators (bucket capacity of 10 cubic meters and 8) and two smaller bucket capacity of about 5 cubic meters.

28. Sometimes the technique breaks down. For example at this excavator broke down the main gear and repairing straight in his career. The diameter of the wire ropes hanging limply - 4 cm.

29. And it - now decommissioned veteran honestly given to companies for about 40 years. Despite its age and kind of shabby, grandfather, in an emergency, it can be put into operation in the quarry.

30. dumping and mining reclamation.

At constant depth bowl career is constantly moving in the direction in which lies the limestone. On one side of the pit overburden removal takes place and the production of limestone, on the other - to develop the space is filled with overburden, gravel crushing limestone and black earth.

31.

32. crushing and concentrating plant in dump cars bring screenings produced after crushing limestone and not fit for use. Excavator passes everything on the blade, filling out space career. Then dumps falling asleep before opening a ground and top with black earth.

33. This mechanical shovel smaller - with a bucket of 5 cubes.

34. Next, carried out plowing the land and carried out biological reclamation - sowing land useful plants. A few years later reclaimed land will be reused for agricultural purposes. Earlier career starts right from the planting (right in the picture) and for 20 years has shifted in the 600 meters. Now, there is a field. In future careers may advance by 2, 7 kilometers.

35. Transport operation.

Daily on the line in a career working 12 BelAZ that provide transportation to the overburden dumps, and the limestone mined in the DOP - crushing and beneficiation plant.

36. Belazisty working around the clock in three shifts of eight hours each. During the day, BelAZ walker commits to 100, and transports the limestone mined up to 16 thousand tons. For three months the machine runs the distance from Moscow to Vladivostok.

37. Capacity of the BelAZ is 55 tons more than its own weight. BelAZ trucks with larger capacity in this career to use inappropriate for several reasons: the depth of the quarry, transport distances, production volume, and so on. It is driven by a diesel engine of the mammoth 700 l / s.

38. If the transport of BelAZ something thrown out on the road, such as a large stone, a special wheel bulldozer removes it back to the face, to the excavator.

39. In a career working actively with the dust of the road constantly poured by special Sprinkle. In winter, watering is replaced by grit sand-salt mixture.

40. To make this picture, I had to ask the driver by radio (each item is equipped with a radio station in his career) that he drove off the road watered. Permissible speed in the career of 20 km / h.

41. In a career laid 14 kilometers of technological roads constructed bulk method also has the electrification and substation to feed the excavators. The roads are excellent, for it can be easy to move by car.

42. shop for repair and maintenance of BelAZ.

43.

44. It BelAZ removed the body and the engine.

45. The extracted minerals are brought to the DOP and dumped into a hopper, in front of this truck is weighed and the weight simply by subtracting the empty weight of the load is obtained BelAZ.

46. hopper.

47. Processing of minerals.

It is the first building the factory - the case of large crushing. Here in the jaw crusher comes coarse crushing of large pieces of rock. A fraction the size of a piece of 10 cm.

48. Further down the pipeline material enters the body secondary crushing.

49. As the conveyor belt is transported per day about 15 000 tons of rock.

50. Cone crusher provides secondary crushing.

51. Dodgy system of vibrating screens. In confined production devices separated into fractions (size stones) and distributed on the conveyor.

52. The shop is easy to fit a normal five-story building ...

53. Most small limestone - screenings up to 1 cm are sent to unloading in dump cars for further transport to the dump his career.

54. The case of sorting and loading. Here comes the final product, which is loaded in the w / d cars. The main consumer products - Novolipetsk Steel.

55.

56. In one car included 69 tons of crushed stone.

57.

58. Next comes loaded into trucks.

59. The work in the quarry does not stop at night. For this purpose, excavators working lights.

60.

61. UFOs.

62. 55-ton BelAZ, used to work in the career of a relatively small, but in Mountain the standards and just kids. Someday I will look at the work of the 320-tonner!

63. Night quarry and factory are beautiful!

Source: