1066

Like diamonds mined in Russia (21 photos)

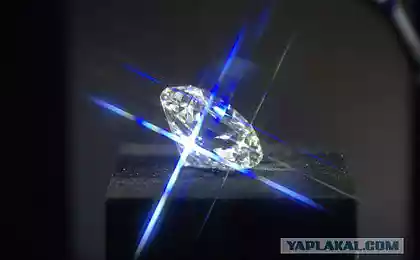

Diamonds are mined from kimberlite pipes are underground volcanic eruption that occurred millions of years ago. Under the influence of high temperatures and enormous pressure was strong carbon lattice and turned into a gem.

Subsequently, the opening of this property will lead to the production of artificial diamonds. But natural stone, of course, is much more valuable.

Today we will see how our country is produced that becomes part of jewelry and is the subject of desire of every woman.

On the photo - view of the main quarry Udachninsky processing plant - "Lucky." Mining operations on the same field were started in 1971 and over the past 25 years Plant is a leading diamond mining company in Russia and one of the largest open-pit mines in the world. In 2010, the share of Udachninsky GOK had 33, 8% of diamond production in terms of value and 12, 5% of the total mining volume in the group "Alrosa».

The first large-scale commercial production of diamonds began in southern Africa about a hundred years ago. In Russia, the kimberlite pipes were discovered only in the middle of the last century - in Yakutia. This discovery marked the beginning of "ALROSA" - today a world leader in diamond mining. Thus, the probable reserves of the company amount to about a third of the world's, and explored enough to sustain current production levels for 25 years without reducing the quality of raw materials. If the numbers, the reserves of diamonds owned by "ALROSA" fields is (according to data released in May 2011) 1, 23 billion carat under Russian classification (1, 014 billion - proven and 0 211 000 000 000 - possible).

The last five years, the company annually allocates exploration of 2, 5 to 3, 5 billion rubles. In 2011, exploration costs amounted to about 4 billion rubles., In 2012 - more than 5, 36 billion rubles.

On their fields, "Alrosa" produces about 35 million carats of diamonds a year, being the world's largest producer of raw materials in physical terms: it accounts for about 97% of Russian oil production and 25% of the world. The content of the diamond grade kimberlite pipes are traditionally small - usually a few carats per tonne. Yakut deposits are advantageous in this respect, and is considered one of the richest in content.

In 2010, the volume of sales of raw diamonds and diamond "Alrosa" was $ 3, 48 billion, and in 2011, according to preliminary data, the company sold products worth $ 5 billion - a record number in its history. The company's revenue in the first half of 2011 under IFRS was 66, 15 billion rubles. (+ 3% YoY) and net profit increased five times to 26 to 27 billion.

Kimberlite pipes are cone-shaped, extending up, so they usually start practicing with quarrying. The project depth of the quarry "Lucky", depicted in these photographs - 600 m. In order to rise from the bottom of the quarry to the surface, dump on the "serpentine" overcomes the path length of about 10 km.

But so it is mined in quarries. The rig does well, which laid the explosive (pictured - the process of laying). By the way, although the diamond is the hardest mineral, it is quite fragile. Therefore, when blasting uses soft technologies, allowing to preserve the integrity of the crystals. After the explosion, the rock fragments are loaded into dump trucks and transported to the processing plant.

Major companies are located in Western Yakutia, in four districts of the Republic of Sakha (Yakutia) - Mirny, Lena, Anabar, Nurba - in one of the harshest regions of the world, with a sharply continental climate, large temperature differences in the permafrost zone. In a good winter lasts up to 8 months, winter temperatures sometimes drop to -60 C.

Therefore, most of the art is made to order - a machine adapted for use in low temperature conditions. As a result, work on the fields are maintained throughout the year in all weather conditions. The quarrying simultaneously involves a large amount of equipment - wheel loaders, dumpers, excavators. Heavy-duty trucks in the park "ALROSA" only about 300, with capacity from 40 to 136 tons. - Mostly "BelAZ", there is also a Cat and Komatsu.

After reaching a certain depth within the open pit reserves are exhausted, the development of open pit becomes unprofitable. The average career developed to a depth of about 600 m. However, the kimberlite pipes lie under the ground to a depth of 1, 5 km. For further mining the mine is built. Underground mining is more costly compared to the quarry, but it is the only cost-effective way to reach deep-seated reserves. In the future, "Alrosa" is going to significantly increase the share of underground mining of diamonds. Now the company is completing the development of the open quarry "Lucky" and is building a parallel underground mine. He is expected to be launched in 2014

The cost of the transition to underground mining of diamonds valued at $ 4.3 billion, but in the future it should lead to a reduction in costs. Largely due to the construction of underground mines duty "ALROSA" in the acute phase of the crisis in 2008 increased by 64% to 134, 4 billion rubles. But the state company in trouble will not leave: she got into the list of strategic enterprises, non-core natural gas assets VTB bought for $ 620 million, and when the demand for diamonds fell, production of "ALROSA" began to buy Gokhran.

The controlling stake "Alrosa" (51%) is in the federal property (from 2006 to 2008 10% of the package belonged VTB), 32% owned by the government of Yakutia, 8% of the control uluses federation subject. In April 2011, the company was transformed from CJSC to OJSC to be able to raise funds on the market. Since the middle of last year, shares of "ALROSA" are traded on the Russian stock exchanges, but the volume of transactions on them is small due to low liquidity (on the stock exchange were only the shares of minority shareholders). In the fall of 2011, the number of shareholders, "Alrosa" entered "Nafta-Moscow" Suleiman Kerimov, skimp on the market for about 1% of the company.

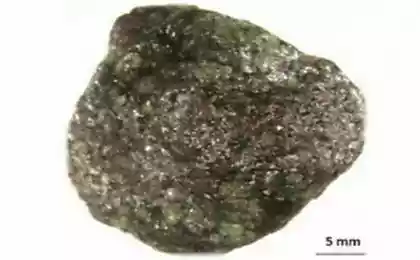

At the word "diamond mines" involuntarily imagine a beautiful picture: the cave, the walls of which gems iridescent. In fact, diamond mine - not the most romantic place on earth. Walls are not sparkling diamond glitter and looking for ore generally easy to assume that it hid the future "girl's best friend." The photo - Working in one of the horizontal ventilation openings of the future underground mine, depth - 380 meters.

Construction of mines takes place in the unique geological conditions. In addition to the permafrost, it is complicated by aggressive groundwater, which due to the high salinity are not only able to wash out the walls of mine workings, but also to eat away (!) Wheel tire dump. In addition, the fields of "ALROSA" present bitumo- and oil shows that also complicate the extraction of diamonds.

In parallel, we are building the future of the mine surface facilities - for example, ventilation and air heater installations. Underground mine "Lucky" will become one of the largest in the world - its capacity is expected to reach 4 million tons of ore per year. This is not the first underground mine company: since 1999, "Alrosa" is working in the mine "International". In addition, in August 2009, the company has commissioned an underground mine "Mir».

It is expected that when all mines are at full capacity, the share of underground mining operations in the total amount of "ALROSA" will rise to 40%. Total in Russia, the company has been producing diamond 9 and 10 indigenous alluvial deposits located in Yakutia and Arkhangelsk region. In addition, the company owns a diamond mining company "Catoca" Angola - together with a local state-owned company "ENDIAMA».

How will the underground mining in the "successful" in 2-3 years? For example - the picture is already working mine "Mir". Diamond mining ore under the ground is carried out mainly shearer penetration (see photo). Also, the company's specialists are studying the possibility of using traditional mining shpurovyh breaking - when a breed destroy explosives planted in drilled wells. Next scheme is the same: take the ore loaders and taken to the surface, where it gets to the processing plant. Now it will go and we will.

The initial stage of the diamond ore beneficiation looks just like any other mineral. Initially, the factory get larger pieces of rock the size of a few meters. After primary crushing in a jaw or cone crushers ore fed to the mill wet autogenous (pictured), where using water rock fragments up to 1, 5 meters are crushed to a size of 0, 5 m or less.

In the next stage spiral classifiers share feedstock, depending on its size and density. The principle of operation is very simple. Water picks up fine particles and carries the drain. The large particles (up to several centimeters) to carry water can no longer - they settle in the lower part of the tank, whereupon a spiral raises them up.

The next stage of enrichment - a roar, so named for the noise that accompanies the work. "Rumble" - a huge vibrating sieve with holes of different sizes allows you to sort the raw materials for various fractions. Separation of raw materials by size groups is necessary because in the future, each of them will be enriched in many ways.

Now we have to somehow isolate diamonds from small pieces of ore, obtained after crushing. Medium size pieces of ore sent to the jigs and heavy medium enrichment: under the influence of the pulsation of water crystals diamond singled out and settle the heavy fraction. The fine "powder" goes through pnevmoflotatsiyu, during which, interacting with the reagents, fine diamond crystals adhere to the foam bubbles.

In the next stage, all the raw materials pass the basic process - separation of X-ray (RLS).

That's just show what happens inside the separator in the process of his work, it will not work: the principle of radar is based on a constant X-ray radiation. Look inside during operation of the separator, to say the least insecure. To describe in words, the method is based on the unique properties of diamond - it is the only mineral that fluoresces in X-rays.

As the conveyor belt inside the separator is constantly moving ground ore is irradiated with X-rays. As soon as the radiation zone gets the diamond, a luminescent solar cells capture the flash and the flow of air "knocks" lighteneth fragment in a separate tank.

Of course, the flow of air inside the separator can separate only one small crystal - with him is eliminated, and a certain amount of waste rock. In fact, the whole process of ore sent only to have to minimize the amount of "empty" material, and then to facilitate manual handling. And the "hand" in the literal sense of the word: professionals choose crystals, clean them and carry out the so-called "final finishing».

No matter how popular now, was the desire to automate all business processes in general, but in the diamond mining do without the human factor is absolutely impossible.

But whose hand it was.

From the workshop final finishing all rough diamonds sent to the sorting center in peace. Here, the raw material is divided by the main groups, and give it an initial evaluation, after which it can be sent for sale through the United Selling Organization «ALROSA».

By the way, about half of the production of "Alrosa" is sold outside Russia. Until recently, the company was selling its diamonds on the world market, using the services of the monopolist De Beers. However, in early 2009 they stopped cooperation and "Alrosa" started reorganization of its distribution system, providing for the sale of direct contracts and equal treatment of foreign and Russian customers, customer base and worked introduced the practice of "long" contracts.

In general, raw materials with each field has its own distinctive features. Experienced experts when looking at a diamond can determine from what is mine he arrived. But this applies only to general signs. Two identical diamonds there. Because there is no organized exchange trading and diamonds, such as gold or copper - it is not a standardized product, every stone has unique characteristics.

This significantly complicates the uniqueness and sorting, and evaluation. In assessing the experts take the basis of three characteristics: size, color, and clarity (lack of inclusions inside, transparency). The most expensive stones - "clean water" is absolutely transparent and have no color expression. Each has a different gradation characteristics. As a result, depending on the size, color and other parameters would be about 8000 possible positions rough.

Subsequently, the opening of this property will lead to the production of artificial diamonds. But natural stone, of course, is much more valuable.

Today we will see how our country is produced that becomes part of jewelry and is the subject of desire of every woman.

On the photo - view of the main quarry Udachninsky processing plant - "Lucky." Mining operations on the same field were started in 1971 and over the past 25 years Plant is a leading diamond mining company in Russia and one of the largest open-pit mines in the world. In 2010, the share of Udachninsky GOK had 33, 8% of diamond production in terms of value and 12, 5% of the total mining volume in the group "Alrosa».

The first large-scale commercial production of diamonds began in southern Africa about a hundred years ago. In Russia, the kimberlite pipes were discovered only in the middle of the last century - in Yakutia. This discovery marked the beginning of "ALROSA" - today a world leader in diamond mining. Thus, the probable reserves of the company amount to about a third of the world's, and explored enough to sustain current production levels for 25 years without reducing the quality of raw materials. If the numbers, the reserves of diamonds owned by "ALROSA" fields is (according to data released in May 2011) 1, 23 billion carat under Russian classification (1, 014 billion - proven and 0 211 000 000 000 - possible).

The last five years, the company annually allocates exploration of 2, 5 to 3, 5 billion rubles. In 2011, exploration costs amounted to about 4 billion rubles., In 2012 - more than 5, 36 billion rubles.

On their fields, "Alrosa" produces about 35 million carats of diamonds a year, being the world's largest producer of raw materials in physical terms: it accounts for about 97% of Russian oil production and 25% of the world. The content of the diamond grade kimberlite pipes are traditionally small - usually a few carats per tonne. Yakut deposits are advantageous in this respect, and is considered one of the richest in content.

In 2010, the volume of sales of raw diamonds and diamond "Alrosa" was $ 3, 48 billion, and in 2011, according to preliminary data, the company sold products worth $ 5 billion - a record number in its history. The company's revenue in the first half of 2011 under IFRS was 66, 15 billion rubles. (+ 3% YoY) and net profit increased five times to 26 to 27 billion.

Kimberlite pipes are cone-shaped, extending up, so they usually start practicing with quarrying. The project depth of the quarry "Lucky", depicted in these photographs - 600 m. In order to rise from the bottom of the quarry to the surface, dump on the "serpentine" overcomes the path length of about 10 km.

But so it is mined in quarries. The rig does well, which laid the explosive (pictured - the process of laying). By the way, although the diamond is the hardest mineral, it is quite fragile. Therefore, when blasting uses soft technologies, allowing to preserve the integrity of the crystals. After the explosion, the rock fragments are loaded into dump trucks and transported to the processing plant.

Major companies are located in Western Yakutia, in four districts of the Republic of Sakha (Yakutia) - Mirny, Lena, Anabar, Nurba - in one of the harshest regions of the world, with a sharply continental climate, large temperature differences in the permafrost zone. In a good winter lasts up to 8 months, winter temperatures sometimes drop to -60 C.

Therefore, most of the art is made to order - a machine adapted for use in low temperature conditions. As a result, work on the fields are maintained throughout the year in all weather conditions. The quarrying simultaneously involves a large amount of equipment - wheel loaders, dumpers, excavators. Heavy-duty trucks in the park "ALROSA" only about 300, with capacity from 40 to 136 tons. - Mostly "BelAZ", there is also a Cat and Komatsu.

After reaching a certain depth within the open pit reserves are exhausted, the development of open pit becomes unprofitable. The average career developed to a depth of about 600 m. However, the kimberlite pipes lie under the ground to a depth of 1, 5 km. For further mining the mine is built. Underground mining is more costly compared to the quarry, but it is the only cost-effective way to reach deep-seated reserves. In the future, "Alrosa" is going to significantly increase the share of underground mining of diamonds. Now the company is completing the development of the open quarry "Lucky" and is building a parallel underground mine. He is expected to be launched in 2014

The cost of the transition to underground mining of diamonds valued at $ 4.3 billion, but in the future it should lead to a reduction in costs. Largely due to the construction of underground mines duty "ALROSA" in the acute phase of the crisis in 2008 increased by 64% to 134, 4 billion rubles. But the state company in trouble will not leave: she got into the list of strategic enterprises, non-core natural gas assets VTB bought for $ 620 million, and when the demand for diamonds fell, production of "ALROSA" began to buy Gokhran.

The controlling stake "Alrosa" (51%) is in the federal property (from 2006 to 2008 10% of the package belonged VTB), 32% owned by the government of Yakutia, 8% of the control uluses federation subject. In April 2011, the company was transformed from CJSC to OJSC to be able to raise funds on the market. Since the middle of last year, shares of "ALROSA" are traded on the Russian stock exchanges, but the volume of transactions on them is small due to low liquidity (on the stock exchange were only the shares of minority shareholders). In the fall of 2011, the number of shareholders, "Alrosa" entered "Nafta-Moscow" Suleiman Kerimov, skimp on the market for about 1% of the company.

At the word "diamond mines" involuntarily imagine a beautiful picture: the cave, the walls of which gems iridescent. In fact, diamond mine - not the most romantic place on earth. Walls are not sparkling diamond glitter and looking for ore generally easy to assume that it hid the future "girl's best friend." The photo - Working in one of the horizontal ventilation openings of the future underground mine, depth - 380 meters.

Construction of mines takes place in the unique geological conditions. In addition to the permafrost, it is complicated by aggressive groundwater, which due to the high salinity are not only able to wash out the walls of mine workings, but also to eat away (!) Wheel tire dump. In addition, the fields of "ALROSA" present bitumo- and oil shows that also complicate the extraction of diamonds.

In parallel, we are building the future of the mine surface facilities - for example, ventilation and air heater installations. Underground mine "Lucky" will become one of the largest in the world - its capacity is expected to reach 4 million tons of ore per year. This is not the first underground mine company: since 1999, "Alrosa" is working in the mine "International". In addition, in August 2009, the company has commissioned an underground mine "Mir».

It is expected that when all mines are at full capacity, the share of underground mining operations in the total amount of "ALROSA" will rise to 40%. Total in Russia, the company has been producing diamond 9 and 10 indigenous alluvial deposits located in Yakutia and Arkhangelsk region. In addition, the company owns a diamond mining company "Catoca" Angola - together with a local state-owned company "ENDIAMA».

How will the underground mining in the "successful" in 2-3 years? For example - the picture is already working mine "Mir". Diamond mining ore under the ground is carried out mainly shearer penetration (see photo). Also, the company's specialists are studying the possibility of using traditional mining shpurovyh breaking - when a breed destroy explosives planted in drilled wells. Next scheme is the same: take the ore loaders and taken to the surface, where it gets to the processing plant. Now it will go and we will.

The initial stage of the diamond ore beneficiation looks just like any other mineral. Initially, the factory get larger pieces of rock the size of a few meters. After primary crushing in a jaw or cone crushers ore fed to the mill wet autogenous (pictured), where using water rock fragments up to 1, 5 meters are crushed to a size of 0, 5 m or less.

In the next stage spiral classifiers share feedstock, depending on its size and density. The principle of operation is very simple. Water picks up fine particles and carries the drain. The large particles (up to several centimeters) to carry water can no longer - they settle in the lower part of the tank, whereupon a spiral raises them up.

The next stage of enrichment - a roar, so named for the noise that accompanies the work. "Rumble" - a huge vibrating sieve with holes of different sizes allows you to sort the raw materials for various fractions. Separation of raw materials by size groups is necessary because in the future, each of them will be enriched in many ways.

Now we have to somehow isolate diamonds from small pieces of ore, obtained after crushing. Medium size pieces of ore sent to the jigs and heavy medium enrichment: under the influence of the pulsation of water crystals diamond singled out and settle the heavy fraction. The fine "powder" goes through pnevmoflotatsiyu, during which, interacting with the reagents, fine diamond crystals adhere to the foam bubbles.

In the next stage, all the raw materials pass the basic process - separation of X-ray (RLS).

That's just show what happens inside the separator in the process of his work, it will not work: the principle of radar is based on a constant X-ray radiation. Look inside during operation of the separator, to say the least insecure. To describe in words, the method is based on the unique properties of diamond - it is the only mineral that fluoresces in X-rays.

As the conveyor belt inside the separator is constantly moving ground ore is irradiated with X-rays. As soon as the radiation zone gets the diamond, a luminescent solar cells capture the flash and the flow of air "knocks" lighteneth fragment in a separate tank.

Of course, the flow of air inside the separator can separate only one small crystal - with him is eliminated, and a certain amount of waste rock. In fact, the whole process of ore sent only to have to minimize the amount of "empty" material, and then to facilitate manual handling. And the "hand" in the literal sense of the word: professionals choose crystals, clean them and carry out the so-called "final finishing».

No matter how popular now, was the desire to automate all business processes in general, but in the diamond mining do without the human factor is absolutely impossible.

But whose hand it was.

From the workshop final finishing all rough diamonds sent to the sorting center in peace. Here, the raw material is divided by the main groups, and give it an initial evaluation, after which it can be sent for sale through the United Selling Organization «ALROSA».

By the way, about half of the production of "Alrosa" is sold outside Russia. Until recently, the company was selling its diamonds on the world market, using the services of the monopolist De Beers. However, in early 2009 they stopped cooperation and "Alrosa" started reorganization of its distribution system, providing for the sale of direct contracts and equal treatment of foreign and Russian customers, customer base and worked introduced the practice of "long" contracts.

In general, raw materials with each field has its own distinctive features. Experienced experts when looking at a diamond can determine from what is mine he arrived. But this applies only to general signs. Two identical diamonds there. Because there is no organized exchange trading and diamonds, such as gold or copper - it is not a standardized product, every stone has unique characteristics.

This significantly complicates the uniqueness and sorting, and evaluation. In assessing the experts take the basis of three characteristics: size, color, and clarity (lack of inclusions inside, transparency). The most expensive stones - "clean water" is absolutely transparent and have no color expression. Each has a different gradation characteristics. As a result, depending on the size, color and other parameters would be about 8000 possible positions rough.

The surprise in the best restaurant in the world (28 photos)

The chapter "Yandex.Ukraine" resigned after ...