1370

Gold mining

The unique field for the extraction of gold, located in the Akmola region, 15 kilometers from Kokshetau.

The history of the country itself reflects the history Vasilkovskaja Mining: The company experienced and stagnation and breakdown, and the present revival under the new name - "Altyntau Kokshetau»

1. Once this place was a small pit, which in 33 years has turned into a huge pit depth of 135 meters and a surface area - 1210 thousand m2

2. Deputy Chief Engineer for the production of Victor Ezhov this year celebrates a kind of symbolic date: 22-year-old boy he came to Vasilskovsky GOK (mining and processing plant), 33 years since worked, and this year celebrated the 55th anniversary.

- I remember when I came back from the army, I was called a master here, but due to the fact that a week stretched out, has got a mechanic - he smiles. - I had to work hard to initially promoted to master, well, then go all the way.

3. Yezhov - one of those who remember how in the early '80s there was a shallow pit. It increases very slowly, in the mid-90s there was even a time when the production of and does not produce. Gold prices then reached a record fall to $ 260 an ounce, and money to develop a career simply did not exist. People were out of work for months, waiting for a call. With the advent of investment already in the mid-2000s gold mining at the deposit received a second wind. For the revival of the production it took $ 700 million, but only for the last two years managed to get as much gold as previously mined for two decades - 11, 5 tons. In 2010, at the suggestion of the Head of State Vasilkovsky mine was renamed the company «Altyntau Kokshetau»

4. Now the work is carried out on a career nonstop

5. 24 hours a day going on the same action: excavator bucket gaining gold ore and dumped into huge Kata (approx .: Cat - from «Caterpillar», manufacturer of dump trucks and other mining equipment). And those already driven her to the crusher, from where the ore on the conveyor belt comes to the factory where it will be retrieved from the gold

6. The design capacity - 8 million tons of ore per year. While the extract - 6 per tonne of ore accounts for 2 grams of gold. It is because of these tiny particles is done such tremendous work

7.

8. To replace an old "BelAZ" came dump "CAT 777". One such SAT weighs 70 tons, while its capacity is from 90 to 100 tons. It is like a giant ant that can lift a load greater than its weight. And as they say the drivers to manage it even easier than a car

9. When Sata just purchased, each car was given its nickname. Now, career touring: "Jaguar", "Tiger", "Golden Antelope", "Vanguard", "Excellent" and even touching "Orange»

10. Sergei Deacons, bulldozer CAT D10, working at the company for 12 years.

- It is now well: in the car air conditioner, stove, cleanliness! And earlier in the elbow and heating all day in the mud. Ah, but what's there to remember!

11. Machinist grader CAT-16 M Adilbek Kayyrbekov also remember the difference between past and present technology. - Earlier grader was with the wheel, and now without, on the levers work.

12. And this machine - the biggest excavator in the world The RH 120-E TEREX. Long-term performance of his 2000 tons per hour. Only one bucket has a capacity of 15 cubic meters and a huge body of Satan, he fills in just a few times

13. Prior to that, the process of extraction of gold produced by the method of heap leaching. This is where the ore is irrigated with a solution of sodium cyanide and the gold extracted from the rock. But this method allows you to effectively process only the oxidized ore reserves gradually decreases, and processing of more refractory sulfide ores require new technologies and significant investment. Who loosening rocks produced by drilling and blasting, and to extract gold using more sophisticated technology combined with traditional operations: flotation, gravity and hydrometallurgy

14. Develop career starts against the surveyor works. Dmitry hide and seek with the brigade makes measurements of deposits, outlines a work plan and monitors compliance with strict technological regime. Then comes the turn of geologists that determine the presence of gold-bearing ore

15. When it's time to drillers. Assistant driver rig Erken Shamgunov shows how they drill a small hole depth of 16 meters, which will be laid explosives

16.

17.

18.

19. Explosions produce twice a week. An hour before all the people and equipment leaving the quarry, for security turned off electricity

20.

21. And then begins the same process: Excavator raking ore trucks and transported it to the crusher

22.

23.

24. The ore from the mine is fed into a hopper of a large crusher crushing. There she was crushed to a size (fraction) of 350 mm, where it first goes to the roll-press, and then a ball mill

25.

26.

27. Milling is carried out in two stages. The first stage takes place in the semi-autogenous mill, after which ground ore is sent to the screening. Larger stones are sent to recrushing and fine ore goes to the second stage ball mill

28.

29. After all the steps of crushing the ore milled, finally reaches a stage where gold extraction begins

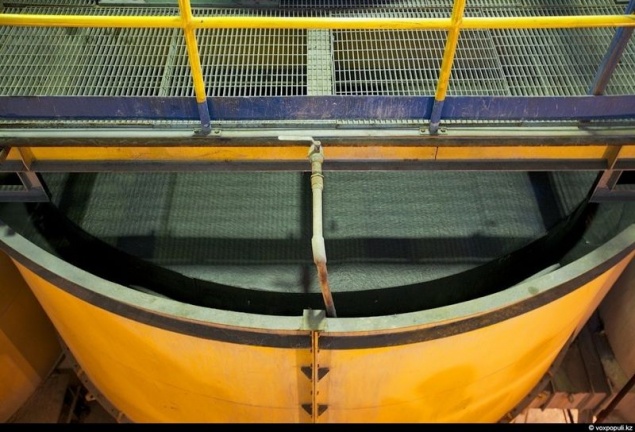

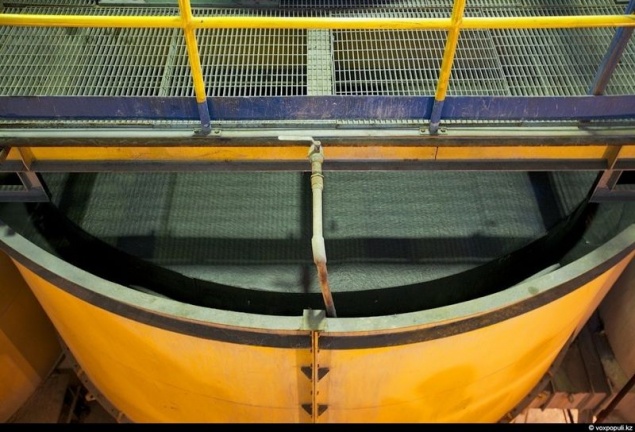

30. In 2007 Altyntau Kokshetau start construction of a unique gold processing plant. We build it quickly - in just two years. At the opening ceremony, President Nursultan Nazarbayev said that Kazakhstan is the largest, and indeed in the world, a plant that will produce and deliver the gold.

- At full capacity plant will produce 15 tons of gold a year. Kazakhstan now produces more than 20 tonnes, that is, going to 35 tons a year, we will be among the 15 largest gold mining countries in the world - he said.

31. As in any regime object, entrance here is strictly limited. Guard carefully inspect each incoming

32. Before the entrance is a full length mirror, a visitor could feel the importance of responsible

33. This control room, from where you can watch the entire production cycle. This is where you can also personally and not on the monitors to follow the work process of flotation and gravity separation

34. This is one of a kind ball mill «Outotec», designed specifically for «Altyntau». More similar design of this size do not have anybody in the world

35. But this flotation machine is designed for the separation of gold and other nonferrous metals

36. Flotation machine operates as follows. The upper cylindrical portion is supplied with water, and in a separate branch of the pre aerated treated reagent slurry (a mixture of water and rock). Concentric tubular aerator supplied with compressed air and bubbles mineralization occurs. These bubbles and adhere the gold particles, which is further concentrated and filtered

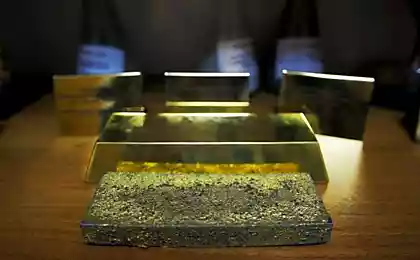

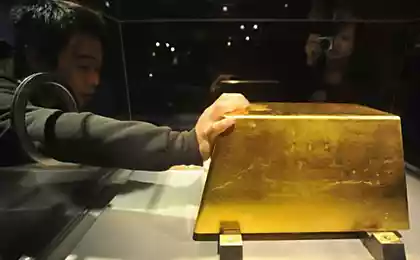

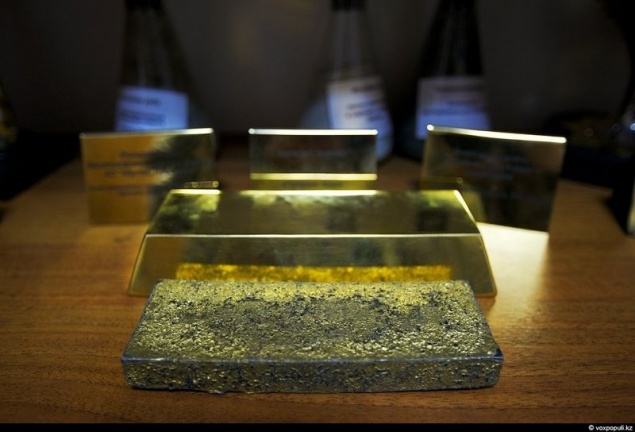

37. Department of flotation and gravity

38. Gravitational process based on the use of gravity, in which the minerals are separated from the gangue by the difference in their density and particle size. This principle is illustrated by the separation of sand from the sawdust when they were thrown into the water: sawdust float and the sand sinks in water

39.

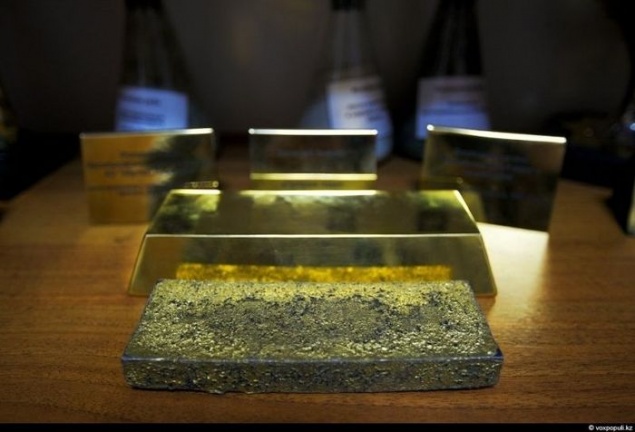

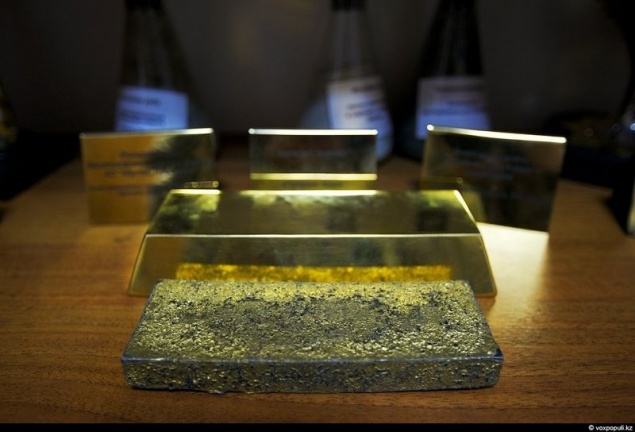

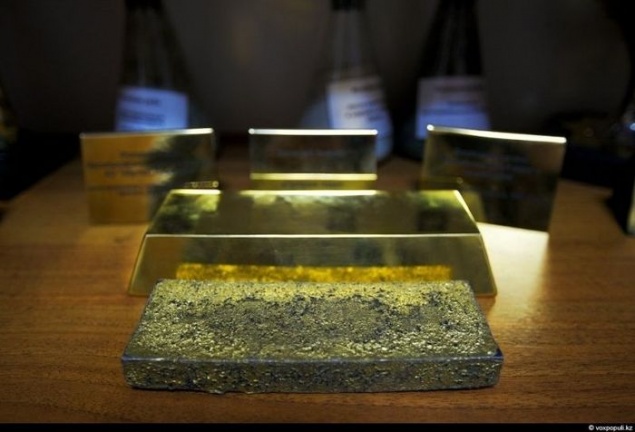

40. The consistency of the final product resembles dirt, but, perhaps, the most expensive "dirt" on the ground

41.

42. This separation of hydrometallurgy, where gold is also recovered from the ore with an aqueous solution with certain chemicals

43. However, the output is the so-called dore - gold-silver alloy containing about 80 percent gold and 20 percent silver. He was sent to the refinery plant, where it is converted into a ready-made bullion. In one of these stories, we show how this bar of gold can get the highest order. Stay tuned!

Source: www.voxpopuli.kz

The history of the country itself reflects the history Vasilkovskaja Mining: The company experienced and stagnation and breakdown, and the present revival under the new name - "Altyntau Kokshetau»

1. Once this place was a small pit, which in 33 years has turned into a huge pit depth of 135 meters and a surface area - 1210 thousand m2

2. Deputy Chief Engineer for the production of Victor Ezhov this year celebrates a kind of symbolic date: 22-year-old boy he came to Vasilskovsky GOK (mining and processing plant), 33 years since worked, and this year celebrated the 55th anniversary.

- I remember when I came back from the army, I was called a master here, but due to the fact that a week stretched out, has got a mechanic - he smiles. - I had to work hard to initially promoted to master, well, then go all the way.

3. Yezhov - one of those who remember how in the early '80s there was a shallow pit. It increases very slowly, in the mid-90s there was even a time when the production of and does not produce. Gold prices then reached a record fall to $ 260 an ounce, and money to develop a career simply did not exist. People were out of work for months, waiting for a call. With the advent of investment already in the mid-2000s gold mining at the deposit received a second wind. For the revival of the production it took $ 700 million, but only for the last two years managed to get as much gold as previously mined for two decades - 11, 5 tons. In 2010, at the suggestion of the Head of State Vasilkovsky mine was renamed the company «Altyntau Kokshetau»

4. Now the work is carried out on a career nonstop

5. 24 hours a day going on the same action: excavator bucket gaining gold ore and dumped into huge Kata (approx .: Cat - from «Caterpillar», manufacturer of dump trucks and other mining equipment). And those already driven her to the crusher, from where the ore on the conveyor belt comes to the factory where it will be retrieved from the gold

6. The design capacity - 8 million tons of ore per year. While the extract - 6 per tonne of ore accounts for 2 grams of gold. It is because of these tiny particles is done such tremendous work

7.

8. To replace an old "BelAZ" came dump "CAT 777". One such SAT weighs 70 tons, while its capacity is from 90 to 100 tons. It is like a giant ant that can lift a load greater than its weight. And as they say the drivers to manage it even easier than a car

9. When Sata just purchased, each car was given its nickname. Now, career touring: "Jaguar", "Tiger", "Golden Antelope", "Vanguard", "Excellent" and even touching "Orange»

10. Sergei Deacons, bulldozer CAT D10, working at the company for 12 years.

- It is now well: in the car air conditioner, stove, cleanliness! And earlier in the elbow and heating all day in the mud. Ah, but what's there to remember!

11. Machinist grader CAT-16 M Adilbek Kayyrbekov also remember the difference between past and present technology. - Earlier grader was with the wheel, and now without, on the levers work.

12. And this machine - the biggest excavator in the world The RH 120-E TEREX. Long-term performance of his 2000 tons per hour. Only one bucket has a capacity of 15 cubic meters and a huge body of Satan, he fills in just a few times

13. Prior to that, the process of extraction of gold produced by the method of heap leaching. This is where the ore is irrigated with a solution of sodium cyanide and the gold extracted from the rock. But this method allows you to effectively process only the oxidized ore reserves gradually decreases, and processing of more refractory sulfide ores require new technologies and significant investment. Who loosening rocks produced by drilling and blasting, and to extract gold using more sophisticated technology combined with traditional operations: flotation, gravity and hydrometallurgy

14. Develop career starts against the surveyor works. Dmitry hide and seek with the brigade makes measurements of deposits, outlines a work plan and monitors compliance with strict technological regime. Then comes the turn of geologists that determine the presence of gold-bearing ore

15. When it's time to drillers. Assistant driver rig Erken Shamgunov shows how they drill a small hole depth of 16 meters, which will be laid explosives

16.

17.

18.

19. Explosions produce twice a week. An hour before all the people and equipment leaving the quarry, for security turned off electricity

20.

21. And then begins the same process: Excavator raking ore trucks and transported it to the crusher

22.

23.

24. The ore from the mine is fed into a hopper of a large crusher crushing. There she was crushed to a size (fraction) of 350 mm, where it first goes to the roll-press, and then a ball mill

25.

26.

27. Milling is carried out in two stages. The first stage takes place in the semi-autogenous mill, after which ground ore is sent to the screening. Larger stones are sent to recrushing and fine ore goes to the second stage ball mill

28.

29. After all the steps of crushing the ore milled, finally reaches a stage where gold extraction begins

30. In 2007 Altyntau Kokshetau start construction of a unique gold processing plant. We build it quickly - in just two years. At the opening ceremony, President Nursultan Nazarbayev said that Kazakhstan is the largest, and indeed in the world, a plant that will produce and deliver the gold.

- At full capacity plant will produce 15 tons of gold a year. Kazakhstan now produces more than 20 tonnes, that is, going to 35 tons a year, we will be among the 15 largest gold mining countries in the world - he said.

31. As in any regime object, entrance here is strictly limited. Guard carefully inspect each incoming

32. Before the entrance is a full length mirror, a visitor could feel the importance of responsible

33. This control room, from where you can watch the entire production cycle. This is where you can also personally and not on the monitors to follow the work process of flotation and gravity separation

34. This is one of a kind ball mill «Outotec», designed specifically for «Altyntau». More similar design of this size do not have anybody in the world

35. But this flotation machine is designed for the separation of gold and other nonferrous metals

36. Flotation machine operates as follows. The upper cylindrical portion is supplied with water, and in a separate branch of the pre aerated treated reagent slurry (a mixture of water and rock). Concentric tubular aerator supplied with compressed air and bubbles mineralization occurs. These bubbles and adhere the gold particles, which is further concentrated and filtered

37. Department of flotation and gravity

38. Gravitational process based on the use of gravity, in which the minerals are separated from the gangue by the difference in their density and particle size. This principle is illustrated by the separation of sand from the sawdust when they were thrown into the water: sawdust float and the sand sinks in water

39.

40. The consistency of the final product resembles dirt, but, perhaps, the most expensive "dirt" on the ground

41.

42. This separation of hydrometallurgy, where gold is also recovered from the ore with an aqueous solution with certain chemicals

43. However, the output is the so-called dore - gold-silver alloy containing about 80 percent gold and 20 percent silver. He was sent to the refinery plant, where it is converted into a ready-made bullion. In one of these stories, we show how this bar of gold can get the highest order. Stay tuned!

Source: www.voxpopuli.kz