983

How to extract zolotishko

Pure gold - a soft yellow metal. It is because of this, as the wiki, where the name of the color 'yellow'. Gold - a very heavy metal: a ball of pure gold with a diameter of 46 mm (less than a tennis ball) has a mass of 1 kg. Gold is very malleable. From a piece of gold weighing one gram can be stretched into a wire length of three kilometers and produce gold foil 500 times thinner than a human hair. The softness of pure gold is so high that it can be scratched with a fingernail. Gold is almost inert metal and a little than react. That is why, in your computer all the contacts are gold-plated.

The content of gold in the ground is very low. If all the gold would be evenly scattered in the earth's crust, the halftone land could be obtained the order of one gram of pure gold. The fields and sections, dramatically enriched in gold are numerous. Gold is contained in water. Of the 250 tons (liters correct, although given the density of water = 1 - it does not matter) of seawater can get about 1 gram of gold.

Users gold mined since time immemorial. With gold mankind has faced in the V th. BC. e. in Neolithic due to its spread in the native state. In the history of mankind produced about 140 thousand. Tons of gold.

Gold may be produced in different ways. All methods of industrial and commercial production of gold based on the physicochemical properties of gold.

Flushing

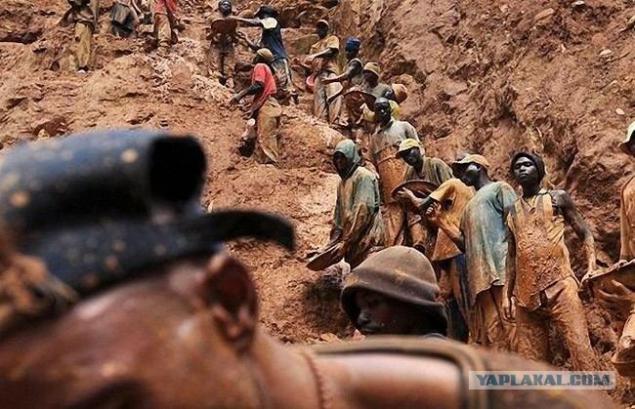

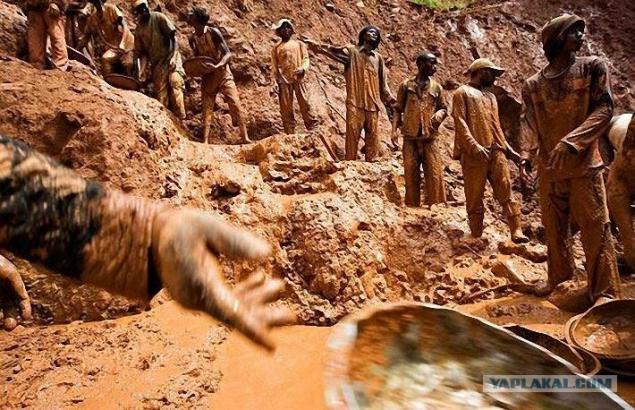

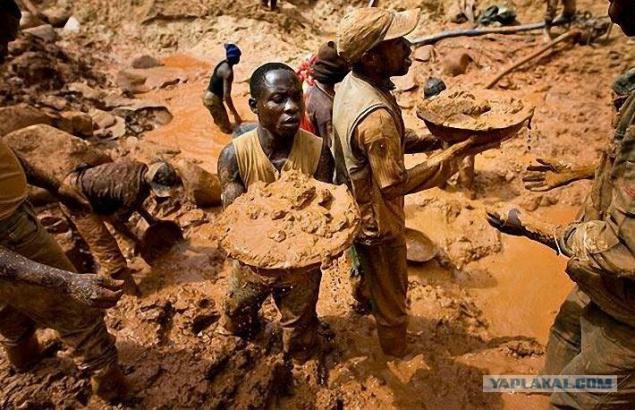

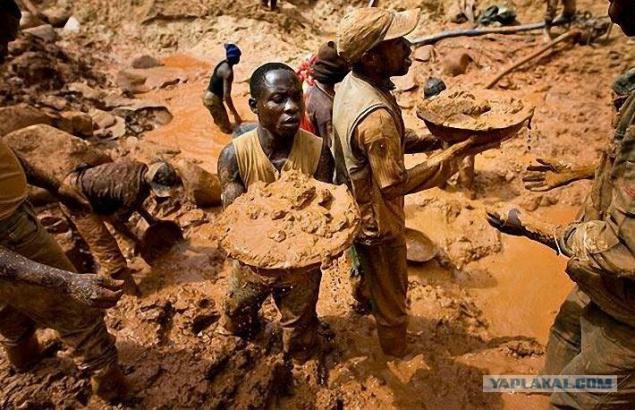

The technology relies on a high washing density of gold, whereby the gold in washing water settles down and the lighter metals and minerals washed. The small amounts of gold can be washed by hand and a tray. Wash, complex process, long and tedious. This method of production is most developed in the underdeveloped countries. This method of extraction of gold has historically been the first, and it is very cheap because it does not require the construction of expensive plants, and in the case of river sediments do not need to break up the rock. Economic viability has gold placers containing more than 0, 1 g per 1 cubic meter of loose rock

Amalgamation

The technology is based on the ability of the amalgamation of mercury with gold to form a compound. For this gold ore is crushed and added mercury amalgam is obtained, i.e. a mixture of mercury and heavy metals contained in the ore. Then this whole mixture was treated in a special way. The method is quite good, but it requires expensive equipment and reagents. It is known that mercury vapor is highly toxic.

Cyanidation

The technology is based on the ability of hydrocyanic acid and its soley- cyanide to dissolve gold in itself. I do not know whether the poison dissolves or not gold, but from my own experience that not only hydrogen cyanide can dissolve gold, but also "aqua regia" - a mixture of concentrated nitric and sulfuric acids. As a child, fond of chemistry and dabbled with gold zolotishko washing dishes, for what often is punished by their parents. Gold pan out very little, but the process was fascinating.

There are several methods of extraction, for example, regeneration, etc. But I would not go into chemistry ...

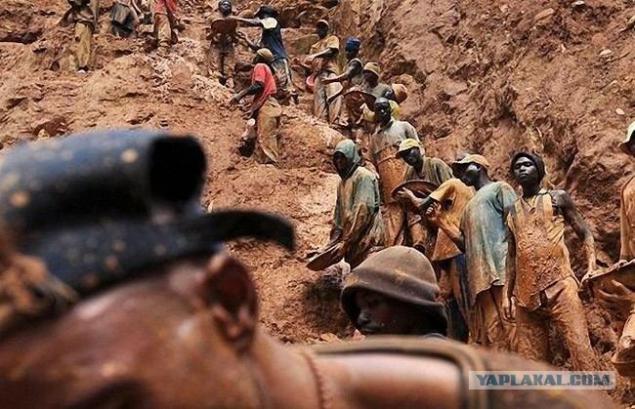

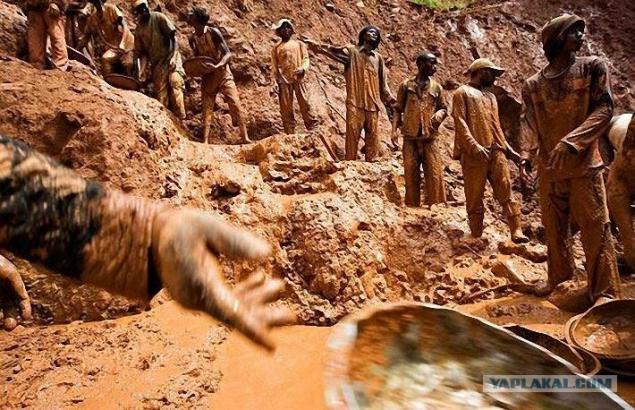

The pictures shown by gold mining in the Congo washing

Source:

The content of gold in the ground is very low. If all the gold would be evenly scattered in the earth's crust, the halftone land could be obtained the order of one gram of pure gold. The fields and sections, dramatically enriched in gold are numerous. Gold is contained in water. Of the 250 tons (liters correct, although given the density of water = 1 - it does not matter) of seawater can get about 1 gram of gold.

Users gold mined since time immemorial. With gold mankind has faced in the V th. BC. e. in Neolithic due to its spread in the native state. In the history of mankind produced about 140 thousand. Tons of gold.

Gold may be produced in different ways. All methods of industrial and commercial production of gold based on the physicochemical properties of gold.

Flushing

The technology relies on a high washing density of gold, whereby the gold in washing water settles down and the lighter metals and minerals washed. The small amounts of gold can be washed by hand and a tray. Wash, complex process, long and tedious. This method of production is most developed in the underdeveloped countries. This method of extraction of gold has historically been the first, and it is very cheap because it does not require the construction of expensive plants, and in the case of river sediments do not need to break up the rock. Economic viability has gold placers containing more than 0, 1 g per 1 cubic meter of loose rock

Amalgamation

The technology is based on the ability of the amalgamation of mercury with gold to form a compound. For this gold ore is crushed and added mercury amalgam is obtained, i.e. a mixture of mercury and heavy metals contained in the ore. Then this whole mixture was treated in a special way. The method is quite good, but it requires expensive equipment and reagents. It is known that mercury vapor is highly toxic.

Cyanidation

The technology is based on the ability of hydrocyanic acid and its soley- cyanide to dissolve gold in itself. I do not know whether the poison dissolves or not gold, but from my own experience that not only hydrogen cyanide can dissolve gold, but also "aqua regia" - a mixture of concentrated nitric and sulfuric acids. As a child, fond of chemistry and dabbled with gold zolotishko washing dishes, for what often is punished by their parents. Gold pan out very little, but the process was fascinating.

There are several methods of extraction, for example, regeneration, etc. But I would not go into chemistry ...

The pictures shown by gold mining in the Congo washing

Source: