2044

Extract gold from the motherboard (18 pics + text)

Many readers will know that gold (chemical symbol Au) used in the jewelry industry. But not all suspect that it is used in the electronics industry (including computer components) due to excellent thermal and electrical conductivity, resistance to oxidation (i.e. to corrosion) and stability. The computer industry potreblinet several hundred tons of metal per year (318 tons in 2003, for example).

The precious metal can be found in almost all computer components - processors, motherboards, expansion cards, DIMM and so on. Of course, in each kit uses a tiny fraction of gold. But the price of gold in recent years soared, so becoming more cost-effective to get the gold out of old parts, rather than to produce it in the traditional way. It therefore appeared on the market a specialized company engaged in just that.

Today we show you how to get the gold out of old motherboards with their own hands. Please note: the chemicals that were used in the demonstration, very dangerous, especially in the commitments we concentrations. Therefore, we do not recommend repeating this experiment at home.

Gold is present in many elements of the motherboard: connectors IDE, slots, PCI Express, PCI, AGP, ISA, and other ports, bridges, in the processor socket and slots DIMM (SIMM on older motherboards).

These connectors are often coated with a thin layer of gold in a thickness of several microns.

Tools

The first phase of our experiment is to remove all these contacts and connectors. We will need wire cutters, pliers and cutters, flat and Phillips screwdrivers, as well as a certain amount of time.

For the experiments need a large number of contacts - they just gave our "donor" motherboards.

We also need chemicals and tools.

Electrolysis

To get a few micrograms of gold deposited on the contacts, we need an electrolytic cell. The bath is poured 95% concentrated sulfuric acid. The cathode is made of lead, the anode - copper. Contacts (raw materials) are connected to the anode, which we made in the form of baskets.

When we pass through the cell electric current (we used a conventional battery charger) copper anode (and contacts) is dissolved and deposited on the cathode lead. Gold is not associated with the copper, forming sediment at the bottom of the cell. It should also be noted that during this process the temperature in the bath is significantly increased.

After gold was separated from the contacts, the bath should be given time to settle. Then it should be removed as much of sulfuric acid, after which you can begin to dissolve the residue at the bottom of the electrolytic cell.

Dilution

Be careful and always empty the acid into the water, not vice versa! If you make a mistake, the first drops of water that come into contact with sulfuric acid, instantly evaporate, as acid can be sprayed at the same time.

We had a sulfuric acid solution of different metals (including gold) and waste that should be filtered. Why not filter the acid directly, without diluting it? Simply due to the fact that paper filters will not stand in front of concentrated sulfuric acid.

Dissolution

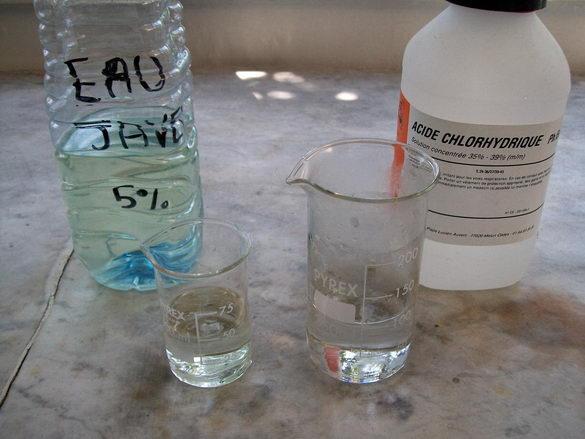

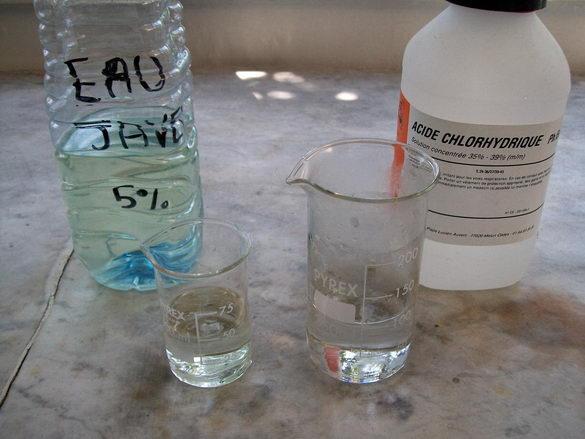

The filter will be a mixture of different metals and waste. We now all that is soluble in a mixture of 35% hydrochloric acid and 5% chlorine bleach (sodium hypochlorite) in a ratio of 2: 1.

NaClO + 2 HCl - & gt; Cl2 + NaCl + H2O

Be careful! This reaction is exothermic, it leads to the release of chlorine gas is very dangerous. Chlorine is used as a chemical weapon in the First World War.

Actually chloro that stood out by mixing hydrochloric acid and chlorine bleach, we will just be used for the dissolution of gold in a gold chloride III.

2 Au + 3 Cl2 - & gt; 2 AuCl3

Again filtering

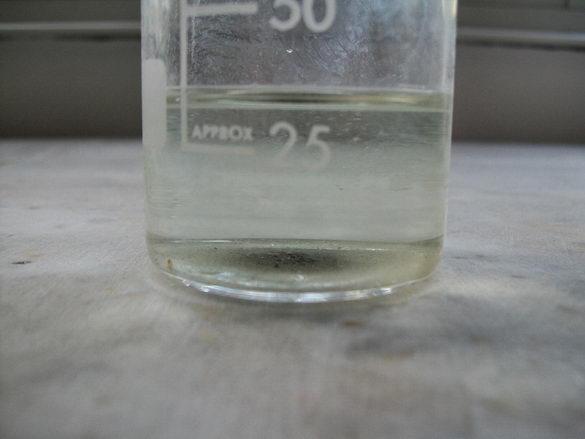

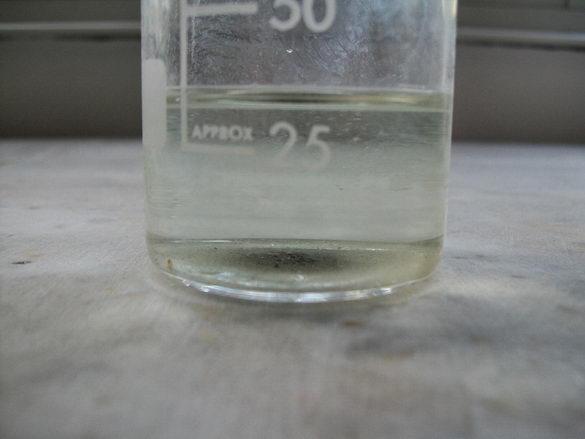

Now we need to filter again. Filter will delay all wastes, leaving only the solution of gold chloride III.

Precipitation

To obtain gold metal, we need to precipitate in the solution. For this purpose, we will use the powdered sodium metabisulfite. In the presence of water gives the sodium metabisulfite, sodium bisulfite.

Na2S2O2 + H2O - & gt; 2 NaHSO3

It will allow us to sodium bisulfite precipitate gold.

3 + 2 NaHSO3 AuCl3 + 3 H2O - & gt; 3 NaHSO4 + 6 HCl + 2 Au

We have to give a solution to settle, and then we get a gray powder on the bottom of the beaker. Do not lose any grains - is a metallic gold!

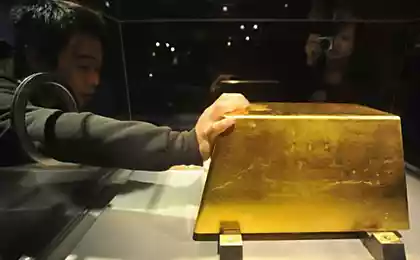

Melting

Now we need to melt the powder in the crucible.

The melting point of gold is 1064 ° C, so we need an oxygen-butane burner.

As a result, we get a nice golden pellet!

Can we call our process economically viable? Definitely not. It only makes sense in the industrial scale. A small pellet of gold, which we received, is only two or three dollars at current prices. And, frankly, companies that extract gold from old computers, use of technology and other chemicals that are even more dangerous. But, you see, it is interesting to know that you can get gold from the motherboard at home.

You can also get gold from expansion cards, processors and chipsets. But this topic is for another article.

The precious metal can be found in almost all computer components - processors, motherboards, expansion cards, DIMM and so on. Of course, in each kit uses a tiny fraction of gold. But the price of gold in recent years soared, so becoming more cost-effective to get the gold out of old parts, rather than to produce it in the traditional way. It therefore appeared on the market a specialized company engaged in just that.

Today we show you how to get the gold out of old motherboards with their own hands. Please note: the chemicals that were used in the demonstration, very dangerous, especially in the commitments we concentrations. Therefore, we do not recommend repeating this experiment at home.

Gold is present in many elements of the motherboard: connectors IDE, slots, PCI Express, PCI, AGP, ISA, and other ports, bridges, in the processor socket and slots DIMM (SIMM on older motherboards).

These connectors are often coated with a thin layer of gold in a thickness of several microns.

Tools

The first phase of our experiment is to remove all these contacts and connectors. We will need wire cutters, pliers and cutters, flat and Phillips screwdrivers, as well as a certain amount of time.

For the experiments need a large number of contacts - they just gave our "donor" motherboards.

We also need chemicals and tools.

Electrolysis

To get a few micrograms of gold deposited on the contacts, we need an electrolytic cell. The bath is poured 95% concentrated sulfuric acid. The cathode is made of lead, the anode - copper. Contacts (raw materials) are connected to the anode, which we made in the form of baskets.

When we pass through the cell electric current (we used a conventional battery charger) copper anode (and contacts) is dissolved and deposited on the cathode lead. Gold is not associated with the copper, forming sediment at the bottom of the cell. It should also be noted that during this process the temperature in the bath is significantly increased.

After gold was separated from the contacts, the bath should be given time to settle. Then it should be removed as much of sulfuric acid, after which you can begin to dissolve the residue at the bottom of the electrolytic cell.

Dilution

Be careful and always empty the acid into the water, not vice versa! If you make a mistake, the first drops of water that come into contact with sulfuric acid, instantly evaporate, as acid can be sprayed at the same time.

We had a sulfuric acid solution of different metals (including gold) and waste that should be filtered. Why not filter the acid directly, without diluting it? Simply due to the fact that paper filters will not stand in front of concentrated sulfuric acid.

Dissolution

The filter will be a mixture of different metals and waste. We now all that is soluble in a mixture of 35% hydrochloric acid and 5% chlorine bleach (sodium hypochlorite) in a ratio of 2: 1.

NaClO + 2 HCl - & gt; Cl2 + NaCl + H2O

Be careful! This reaction is exothermic, it leads to the release of chlorine gas is very dangerous. Chlorine is used as a chemical weapon in the First World War.

Actually chloro that stood out by mixing hydrochloric acid and chlorine bleach, we will just be used for the dissolution of gold in a gold chloride III.

2 Au + 3 Cl2 - & gt; 2 AuCl3

Again filtering

Now we need to filter again. Filter will delay all wastes, leaving only the solution of gold chloride III.

Precipitation

To obtain gold metal, we need to precipitate in the solution. For this purpose, we will use the powdered sodium metabisulfite. In the presence of water gives the sodium metabisulfite, sodium bisulfite.

Na2S2O2 + H2O - & gt; 2 NaHSO3

It will allow us to sodium bisulfite precipitate gold.

3 + 2 NaHSO3 AuCl3 + 3 H2O - & gt; 3 NaHSO4 + 6 HCl + 2 Au

We have to give a solution to settle, and then we get a gray powder on the bottom of the beaker. Do not lose any grains - is a metallic gold!

Melting

Now we need to melt the powder in the crucible.

The melting point of gold is 1064 ° C, so we need an oxygen-butane burner.

As a result, we get a nice golden pellet!

Can we call our process economically viable? Definitely not. It only makes sense in the industrial scale. A small pellet of gold, which we received, is only two or three dollars at current prices. And, frankly, companies that extract gold from old computers, use of technology and other chemicals that are even more dangerous. But, you see, it is interesting to know that you can get gold from the motherboard at home.

You can also get gold from expansion cards, processors and chipsets. But this topic is for another article.