1241

Volkswagen Phaeton - "people's car" premium

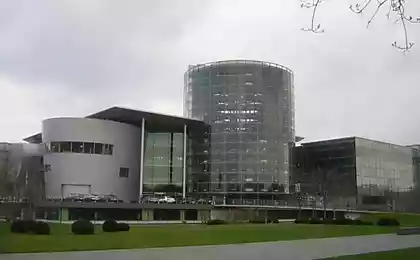

A few kilometers from the historic center of Dresden is the Volkswagen car plant. It produces premium cars Volkswagen Phaeton. The plant itself is called the Gläserne Manufaktur, which means transparent factory. And it is called so not by accident. All external and internal walls are almost all made of glass. The building is located in the city park. No harmful production is not here. In the factory, there is only the final assembly of cars and all the components are supplied from other Volkswagen plants. The official opening of the plant took place on March 23, 2002. It is a new concept of the company that allows potential customers to get acquainted with the production. Let's take a look inside this exciting facilities.

Here is a car is on the first floor of the building. As part of a small tour dedicated staff very interesting talks about the factory and production. I think that there will be interesting not only to fans of the Volkswagen brand, because this factory is very different from a conventional automobile. Photos little, because it was not allowed to take pictures. Due to the fact that employees do not really like. Still on the ground floor there is an interesting simulation of a car with the engine W12.

In order to work at the company must constantly supply components. And since the factory is located in the heart of Dresden, this would mean the constant movement of trucks in the center. This problem was solved in a very interesting way. On the outskirts of town, near the exit of the motorway it was built a special logisticheky center, where wagons are supplied to all components. From this logistics center was built a special tram line that goes directly into the ground floor of the factory.

Ready Body comes from Zwickau. The entire assembly process takes four days. Almost every avtombil - a car in an individual configuration, depending on the wishes of a happy future owner. By the way, if there is such a desire, it is possible to attend the assembly of your car. And some even to pouchavstvovat opertsii in this exciting process. Pay attention to the light. For lighting plants were chosen lamp emitting light of the wavelength, which, according to the assurances of scientists ensures minimum fatigue staff. These lamps are directed at the ceiling, where there are special lenses. Thus, in the shops to obtain a uniform illumination with a virtually complete absence of shadows. And a bright light does not blind factory residents of nearby houses. It's amazing to what the smallest details everything is thought out. And here's own assembly line. He moves slowly and silently. The floor is made from a special flooring, which has excellent sound-absorbing properties. Therefore, in the shops very quiet.

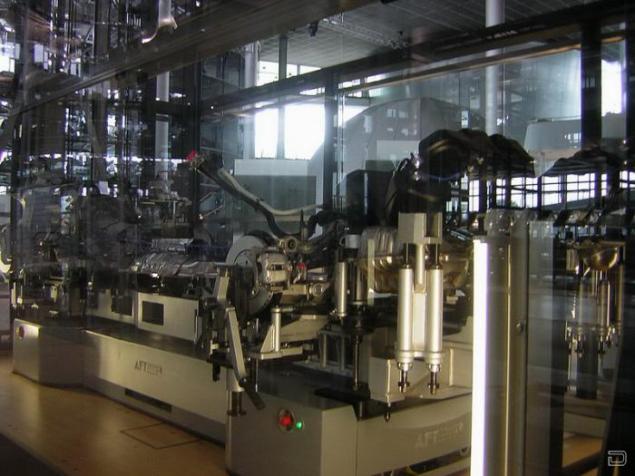

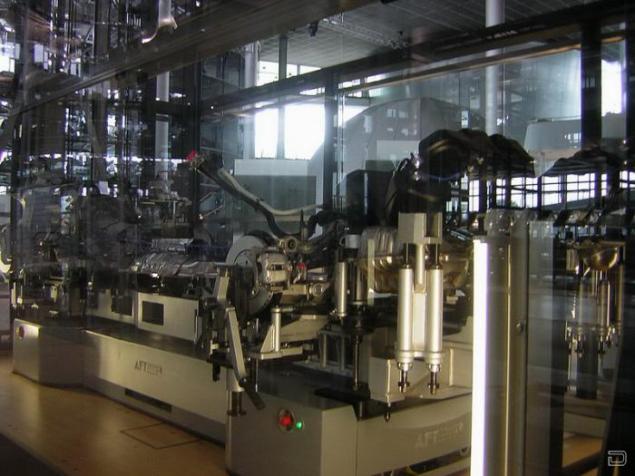

Each surgery is usually only one employee. Rarely more. Robots are here just to have two operations: to install windshields and wheels. And so the assembly is fully manual. But oburudovanie enough "smart". For example, when a twist of nuts, the appropriate tool automatically from the computer memory sets the correct tightening torque. So Underturned or tapered connection immediately excluded.

Here a worker installs a back door on the left. A box on the right is still without doors. With each car travels spetsalno folder where the vehicle contains equipment. So for each operation the worker knows what details should be placed.

Big thumbs up on the right and left of the vehicle body - modules for storage of accessories. Since the vehicle's equipment is known in advance, and are equipped with these modules is still in the logistics center.

In the background it is very interesting and important operation: Hochzeit, which translated from German means "wedding". This compound, integrally stand and transmission. Actually there as it is born, and the car, because before the "wedding," it's all just parts of it:)

This frame can be clearly seen for example in the dashboard assembly. Here is difficult to discern where the actual conveyor itself. The car body with an employee with components and modules are on the assembly line, and move, and where is the dashboard - it is not a conveyor. Basically, on the floor you can see the line between moving and stationary parts of the floor. A small gray cabinet with a monitor near the worker - a module with the tools.

Here in a glass elevator to the automatic trolley is tranmissiya assembly. The truck and the floor are built special magnetic sensors, so that they move AUTOMATIC themselves delivering the chassis exactly to the assembly. On top of the chassis is slowly lowered the body, and after accurate docking assembly takes place.

At this stage, we see a nearly complete vehicles. At the end of the assembly after filling of all technological liquids, the car enters the speftsialny "light tunnel" where the careful visual inspection. And in the end, the car is started and it izemeryayut harakterestiki special dynamometer devices. On the ground floor there is a small factory track for a test drive. Each car goes then another 70-minute test drive in the city, on the highway and the motorway, which passes within 40 km. And only after that, if all goes well, the car can be delivered to the customer. Here is such a quality control!

Finished products are placed here in this glass tower, from which is taken by the owner. In the range of the most powerful engines - the petrol is W12. But such machines to establish rare. As we have said, only 3% of the cars with the engine. The most massive engine - a three-liter V6 TDI diesel with an average rate of about 9 liters of diesel per 100 kilometers. The maximum speed of the vehicle with the "weak" engine of 237 kilometers per hour. In all other, more powerful, it "rolls over" 250 but of course electronically limited at this level.

During the year there is produced about 6,000 cars. A very modest figure when divided by 365 days to get the Middle 16-17 cars a day. As said, the crisis has not touched the model Phaeton, and on it there is a stable demand. More from the statistical: the number of new car sales premium in Germany Phaeton concedes Mercedes S, Audi A8, and seven BMW. But this is a very good result, because it is made only in 2002, while the other famous "Germans" are present in this segment for decades.

So do the "people's car»:)

Here is a car is on the first floor of the building. As part of a small tour dedicated staff very interesting talks about the factory and production. I think that there will be interesting not only to fans of the Volkswagen brand, because this factory is very different from a conventional automobile. Photos little, because it was not allowed to take pictures. Due to the fact that employees do not really like. Still on the ground floor there is an interesting simulation of a car with the engine W12.

In order to work at the company must constantly supply components. And since the factory is located in the heart of Dresden, this would mean the constant movement of trucks in the center. This problem was solved in a very interesting way. On the outskirts of town, near the exit of the motorway it was built a special logisticheky center, where wagons are supplied to all components. From this logistics center was built a special tram line that goes directly into the ground floor of the factory.

Ready Body comes from Zwickau. The entire assembly process takes four days. Almost every avtombil - a car in an individual configuration, depending on the wishes of a happy future owner. By the way, if there is such a desire, it is possible to attend the assembly of your car. And some even to pouchavstvovat opertsii in this exciting process. Pay attention to the light. For lighting plants were chosen lamp emitting light of the wavelength, which, according to the assurances of scientists ensures minimum fatigue staff. These lamps are directed at the ceiling, where there are special lenses. Thus, in the shops to obtain a uniform illumination with a virtually complete absence of shadows. And a bright light does not blind factory residents of nearby houses. It's amazing to what the smallest details everything is thought out. And here's own assembly line. He moves slowly and silently. The floor is made from a special flooring, which has excellent sound-absorbing properties. Therefore, in the shops very quiet.

Each surgery is usually only one employee. Rarely more. Robots are here just to have two operations: to install windshields and wheels. And so the assembly is fully manual. But oburudovanie enough "smart". For example, when a twist of nuts, the appropriate tool automatically from the computer memory sets the correct tightening torque. So Underturned or tapered connection immediately excluded.

Here a worker installs a back door on the left. A box on the right is still without doors. With each car travels spetsalno folder where the vehicle contains equipment. So for each operation the worker knows what details should be placed.

Big thumbs up on the right and left of the vehicle body - modules for storage of accessories. Since the vehicle's equipment is known in advance, and are equipped with these modules is still in the logistics center.

In the background it is very interesting and important operation: Hochzeit, which translated from German means "wedding". This compound, integrally stand and transmission. Actually there as it is born, and the car, because before the "wedding," it's all just parts of it:)

This frame can be clearly seen for example in the dashboard assembly. Here is difficult to discern where the actual conveyor itself. The car body with an employee with components and modules are on the assembly line, and move, and where is the dashboard - it is not a conveyor. Basically, on the floor you can see the line between moving and stationary parts of the floor. A small gray cabinet with a monitor near the worker - a module with the tools.

Here in a glass elevator to the automatic trolley is tranmissiya assembly. The truck and the floor are built special magnetic sensors, so that they move AUTOMATIC themselves delivering the chassis exactly to the assembly. On top of the chassis is slowly lowered the body, and after accurate docking assembly takes place.

At this stage, we see a nearly complete vehicles. At the end of the assembly after filling of all technological liquids, the car enters the speftsialny "light tunnel" where the careful visual inspection. And in the end, the car is started and it izemeryayut harakterestiki special dynamometer devices. On the ground floor there is a small factory track for a test drive. Each car goes then another 70-minute test drive in the city, on the highway and the motorway, which passes within 40 km. And only after that, if all goes well, the car can be delivered to the customer. Here is such a quality control!

Finished products are placed here in this glass tower, from which is taken by the owner. In the range of the most powerful engines - the petrol is W12. But such machines to establish rare. As we have said, only 3% of the cars with the engine. The most massive engine - a three-liter V6 TDI diesel with an average rate of about 9 liters of diesel per 100 kilometers. The maximum speed of the vehicle with the "weak" engine of 237 kilometers per hour. In all other, more powerful, it "rolls over" 250 but of course electronically limited at this level.

During the year there is produced about 6,000 cars. A very modest figure when divided by 365 days to get the Middle 16-17 cars a day. As said, the crisis has not touched the model Phaeton, and on it there is a stable demand. More from the statistical: the number of new car sales premium in Germany Phaeton concedes Mercedes S, Audi A8, and seven BMW. But this is a very good result, because it is made only in 2002, while the other famous "Germans" are present in this segment for decades.

So do the "people's car»:)