459

What are and how to choose the right wheels for storage trucks

Warehouse trolleys are quite simple and reliable equipment, the average service life of which is about 15 years. Here everything depends on the reliability of the manufacturer, model, intensity of operation, accuracy of compliance with regulated requirements. The owner must take care of timely service. Periodically, you need to change the wheels, as they are subject to wear.

Wheel design for warehouse trucks

Wheels used to complete warehouse trolleys differ in the type of design. There are options with and without the bracket. The former are more functional due to their mobility. These wheels are able to rotate 360 degrees. They can be found on platform carts. Two-wheeled manual models are simplified as much as possible. They are equipped with permanent wheels, without brackets.

Wheels are classified by type of bearings. The latter can be roller, ball, sliding. The choice depends on the factory equipment. It is believed that ball bearings are more reliable, able to withstand significant loads. Rollers are characterized by ease of movement. Slip bearings are the cheapest, not suitable for intensive operating conditions.

Materials of manufacture of wheels for warehouse trolleys

Polyurethane wheels for warehouse trolleys have become the most widespread. The company "Forklift" offers to buy them for different types of equipment. Monolithic production technology allows to obtain wheels with a number of positive characteristics. Their key strengths are:

In addition to monolithic, sometimes two-layer wheels are used. In this case, the inner part is made of one material, the outer part is made of another. They are used in the production of rubber, nylon, polyamide.

The wheel is always based on a steel rim. Metal is necessarily treated with anticorrosive substances. Here it is important to pay attention to the type and number of fastening holes, the total diameter and other parameters. Not the least is the reliability of the manufacturer. Do not buy products of little-known companies with dubious reputation.

Based on stellana.ru/

Wheel design for warehouse trucks

Wheels used to complete warehouse trolleys differ in the type of design. There are options with and without the bracket. The former are more functional due to their mobility. These wheels are able to rotate 360 degrees. They can be found on platform carts. Two-wheeled manual models are simplified as much as possible. They are equipped with permanent wheels, without brackets.

Wheels are classified by type of bearings. The latter can be roller, ball, sliding. The choice depends on the factory equipment. It is believed that ball bearings are more reliable, able to withstand significant loads. Rollers are characterized by ease of movement. Slip bearings are the cheapest, not suitable for intensive operating conditions.

Materials of manufacture of wheels for warehouse trolleys

Polyurethane wheels for warehouse trolleys have become the most widespread. The company "Forklift" offers to buy them for different types of equipment. Monolithic production technology allows to obtain wheels with a number of positive characteristics. Their key strengths are:

- resistance to mechanical damage;

- slow and uniform abrasion;

- invulnerability to moisture, chemical compounds, low and high temperatures;

- Low noise level when moving equipment.

In addition to monolithic, sometimes two-layer wheels are used. In this case, the inner part is made of one material, the outer part is made of another. They are used in the production of rubber, nylon, polyamide.

The wheel is always based on a steel rim. Metal is necessarily treated with anticorrosive substances. Here it is important to pay attention to the type and number of fastening holes, the total diameter and other parameters. Not the least is the reliability of the manufacturer. Do not buy products of little-known companies with dubious reputation.

Based on stellana.ru/

Shower cabin or bath: which option should be preferred

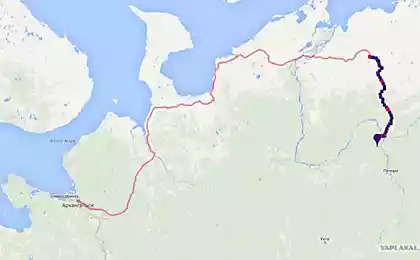

Evacuation of vehicles by methods of full and partial loading