488

Insulation of walls and ceiling with his hands

At home even quiet sounds from neighbors or from the street do not relax and forced to look for ways of protection against noise. Proposed guidelines for sound insulation of walls and ceilings of residential apartments that you can apply to practice independently.

The types of noise and options for addressing

There are two groups of noise — internal and external. Internal noises provide the technical equipment located in the house, as well as sounds related to the life of residents. 70 percent of them are distributed through the slab.

External noise sources are located outside of the building is transportation, plant operations, noise from public places.

The method of formation of internal noise klassificeret both percussive and airy.

At mechanical influence on the overlap appear to impact noises, for example, while moving furniture or repair works.

Air noises are transmitted from the source to the slab through the air, for example, from loud player.

Often the noise transmitted through the ceiling to the walls and posted throughout the building, this method of sound transmission is called indirect.

The problem is solved full or partial completion of all the walls and ceilings of the apartment.

Full soundproofing involves the modification of ceiling, walls of different methods, but requires a full repair of apartments and low cost.

Sometimes the problem can be solved by partial soundproofing, for example, by eliminating structural defects in the junctions of walls with floor slabs or in locations of electrical products. You can also insulate only the ceiling or a wall.

Features of sound insulation of apartments in houses of various typesCannot be allocated type of the building, which has soundproofing better the other, they all present a common problem — poor soundproofing of ceilings.

Feature of prefabricated houses — the solidity of the floors and walls are the same, so indirect transmission of sounds very high. The sound in prefabricated houses is transferred from upper floors, down the walls, and sound insulation of floor slabs is ineffective. In panel houses it is recommended to do a complete soundproofing of the rooms, including the floor.

In the brick houses the walls are thicker slabs, and the sound is extinguished in more massive structures. To reduce noise it is often sufficient to modify only the ceiling.

In frame-monolithic building, the overlapping of the massive room partitions, and exterior walls are often made of lightweight material. As a result, the noise from slabs are transferred to the apartment is via partitions and bearing walls. In houses of this type to deal with the noise start at the stage of construction. Build partitions not to ceiling, but leave a gap of 10-20 mm, subsequently it is filled with sound-absorbing material. From the noisy neighbors on the side are protected by walls, built on frame technology using soundproofing guide profiles. The noise from above is recommended to be reduced with the suspended acoustical ceiling.

Sound insulation materials

Materials for noise protection are divided into two groups:

Sound insulation — to protect the house from the outside penetrating noise. Material properties are enhanced with increasing thickness. Usually used in the composition of special designs. Sound-absorbing — prevent the spread of noise outside the room. Have a fibrous or cellular structure, which allows to absorb the sound. Used to prevent the propagation of sound (e.g., music) outside of the room. The noise level will drop sharply when it first to the wall to secure the sound absorbing material, and then proofing.

For insulation of apartments often buy such insulators:

Mineral wool — retains more than 90 percent of all noise types. Sold in rolls or slabs. The disadvantage is the loss of their ability after getting wet.

Cork is a natural insulating plate material. Retains well impact noise. Downside is high cost.

ISOPLAAT — acoustic Board made of fiber of coniferous trees to reduce all kinds of noise. The thickness is 10-25 mm, the dimensions of the plates 2700х1200 mm. One side is smooth, for finishing.

ISOTEX — light, flexible slab of fiber of coniferous trees to protect against airborne and impact noise. Easy to install, line the walls.

ZIPS — the panel of gypsum-fiber Board and mineral wool with a thickness of 40 to 130 mm. Buy it and because of the possibility to use instead of finishing the walls.

Insulating material for use in the apartments chosen with a dense structure, about 60 kg/m3.

For soundproofing it is not recommended to apply foam, polyurethane foam, polyethylene foam. These materials protect the room against noise, but the level of air noise to lower can't.

Ceiling insulationFor soundproofing ceilings it is recommended to collect acoustic suspended ceiling or suspended ceiling on fibropapilloma suspensions.

Acoustic suspended ceiling

Design effective through the use of special acoustical panels that absorb sound. This method can be used if the ceiling height within 3 m, because the thickness of 120-170 mm. the design Procedure for the system installation:

To the ceiling according to a predetermined scheme record acoustic suspension, to which are connected the elements of the ceiling. For fastening anchors or dowels, screws and vibration isolation mounting assemblies. The suspensions mounted rails acoustic profiles. Length adjustable by 10 mm smaller than the size of the room. The space between the rails is filled with sound-absorbing plates. Completion of work — the fastening of sheets of drywall to the profiles.

The ceiling on fibropapilloma suspensions

The design uses building suspensions for suspended ceiling with built-in anti-vibration blocks. The product prevents the spread of impact noise from the floor to the metal profile of ceiling. Fibropapilloma ceiling height is 170-190 mm, so they are set if the distance from floor to ceiling of 3 m.

The order of installation:

To the ceiling attach vibrapods according to the instructions. To vibrapods is fixed with metal profiles. Fill the space between the profiles with mineral wool for increased sound insulation. Profile attached to the special insulating panel. Panels are fixed to the first thin fabric, for example, the Wolf flees, and then drywall. Between them remains a small gap, which improves sound insulation. Noise insulation wallsof Plasterboard structuresattached To the wall frame profile, departing a couple of inches from the surface. The slit is placed a sound-insulating elements made of rubber or cork.

Frame filled with sound-insulating mats.

The last step is fastening the drywall to the profile.

The main drawback of the method — each design reduces the dimensions of the room 10 cm

Decorative soundproof panelsound insulation properties of the finished panels similar to drywall products. It's a light product, their weight does not exceed 4 lbs. When mounted is fixed to a flat surface. If necessary, on the wall to make a crate and put the slats in a single plane. To the sheathing panels are attached with liquid nails, and are joined together by the method of "tongue in groove". After mounting the decoration of the walls is not required — the surface looks very beautiful thanks to textile or paper finishing. In this way, it is recommended to isolate the apartment is fully and not one wall.

Rolled insulation wallsRoll insulator is fixed to the surface of the Wallpaper glue. The noise level after the work was reduced only by 60 percent. This method is used, for example, during a stay in a rented apartment.

Elimination of construction defectsto Reduce the noise from neighbors is possible if you follow simple recommendations for fixing defects builders.

Electrical outlets and boxesIn apartment buildings to install electrical accessories sometimes penetrate the walls of the through holes. The result is a channel between the neighboring apartments through which noise enters the room.

The problem is solved in the following way:

Remove the power outlet and mounting box. Measure the hole diameter and cut to size a strip of mineral wool, asbestos cloth or cardboard basalt. Install the gasket into the opening until the stop seal putty. It is forbidden to use foam for this purpose because of the high Flammability. Assemble the socket. Similarly, close up the holes for the mounting (terminal) electrical box. They are closed with plastic caps and are under the Wallpaper, you can find them, if you knock in the places of their proposed installation.

The standpipesFor the heating and water pipes through floors are used damping pipe lengths. They have a diameter larger than the diameter of the pipe, so between them is a gap that should be filled with absorbent material and be sealed from the outside with putty. To check the quality of installation remove the top cement layer and inspect the casing. If there are voids between the sleeve and the pipe, clear the gap of debris as deep as possible. Wrap the pipe sound insulation material and seal the joint with cement mortar. From the outside the junction of the cover with silicone sealant.

The joints between the ceiling and wallsIf the house is old, between the slabs and walls can cause cracks. They are not visible under the Wallpaper, and do not spoil the interior of the room, but the sounds are missing. Cracks should be filled with a filler or fluff on top of acrylic sealant.

To ensure that 100 percent soundproofing is impossible, but this is not necessary. Enough that the noise decreased, at least until the non-irritating level. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: //www.rmnt.ru/story/isolation/1061454.htm

The types of noise and options for addressing

There are two groups of noise — internal and external. Internal noises provide the technical equipment located in the house, as well as sounds related to the life of residents. 70 percent of them are distributed through the slab.

External noise sources are located outside of the building is transportation, plant operations, noise from public places.

The method of formation of internal noise klassificeret both percussive and airy.

At mechanical influence on the overlap appear to impact noises, for example, while moving furniture or repair works.

Air noises are transmitted from the source to the slab through the air, for example, from loud player.

Often the noise transmitted through the ceiling to the walls and posted throughout the building, this method of sound transmission is called indirect.

The problem is solved full or partial completion of all the walls and ceilings of the apartment.

Full soundproofing involves the modification of ceiling, walls of different methods, but requires a full repair of apartments and low cost.

Sometimes the problem can be solved by partial soundproofing, for example, by eliminating structural defects in the junctions of walls with floor slabs or in locations of electrical products. You can also insulate only the ceiling or a wall.

Features of sound insulation of apartments in houses of various typesCannot be allocated type of the building, which has soundproofing better the other, they all present a common problem — poor soundproofing of ceilings.

Feature of prefabricated houses — the solidity of the floors and walls are the same, so indirect transmission of sounds very high. The sound in prefabricated houses is transferred from upper floors, down the walls, and sound insulation of floor slabs is ineffective. In panel houses it is recommended to do a complete soundproofing of the rooms, including the floor.

In the brick houses the walls are thicker slabs, and the sound is extinguished in more massive structures. To reduce noise it is often sufficient to modify only the ceiling.

In frame-monolithic building, the overlapping of the massive room partitions, and exterior walls are often made of lightweight material. As a result, the noise from slabs are transferred to the apartment is via partitions and bearing walls. In houses of this type to deal with the noise start at the stage of construction. Build partitions not to ceiling, but leave a gap of 10-20 mm, subsequently it is filled with sound-absorbing material. From the noisy neighbors on the side are protected by walls, built on frame technology using soundproofing guide profiles. The noise from above is recommended to be reduced with the suspended acoustical ceiling.

Sound insulation materials

Materials for noise protection are divided into two groups:

Sound insulation — to protect the house from the outside penetrating noise. Material properties are enhanced with increasing thickness. Usually used in the composition of special designs. Sound-absorbing — prevent the spread of noise outside the room. Have a fibrous or cellular structure, which allows to absorb the sound. Used to prevent the propagation of sound (e.g., music) outside of the room. The noise level will drop sharply when it first to the wall to secure the sound absorbing material, and then proofing.

For insulation of apartments often buy such insulators:

Mineral wool — retains more than 90 percent of all noise types. Sold in rolls or slabs. The disadvantage is the loss of their ability after getting wet.

Cork is a natural insulating plate material. Retains well impact noise. Downside is high cost.

ISOPLAAT — acoustic Board made of fiber of coniferous trees to reduce all kinds of noise. The thickness is 10-25 mm, the dimensions of the plates 2700х1200 mm. One side is smooth, for finishing.

ISOTEX — light, flexible slab of fiber of coniferous trees to protect against airborne and impact noise. Easy to install, line the walls.

ZIPS — the panel of gypsum-fiber Board and mineral wool with a thickness of 40 to 130 mm. Buy it and because of the possibility to use instead of finishing the walls.

Insulating material for use in the apartments chosen with a dense structure, about 60 kg/m3.

For soundproofing it is not recommended to apply foam, polyurethane foam, polyethylene foam. These materials protect the room against noise, but the level of air noise to lower can't.

Ceiling insulationFor soundproofing ceilings it is recommended to collect acoustic suspended ceiling or suspended ceiling on fibropapilloma suspensions.

Acoustic suspended ceiling

Design effective through the use of special acoustical panels that absorb sound. This method can be used if the ceiling height within 3 m, because the thickness of 120-170 mm. the design Procedure for the system installation:

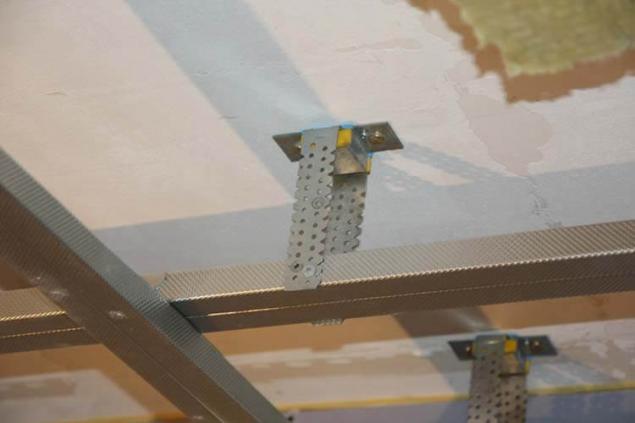

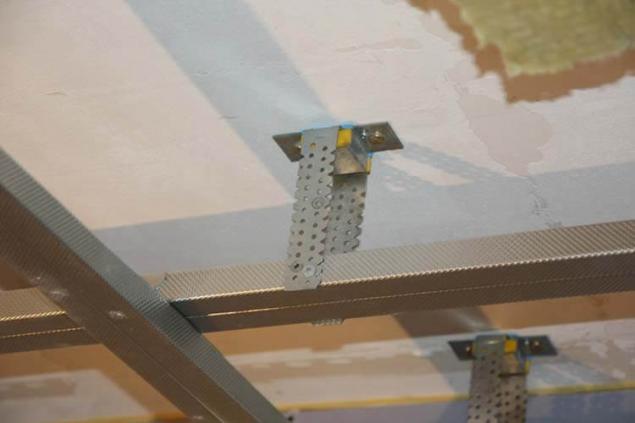

To the ceiling according to a predetermined scheme record acoustic suspension, to which are connected the elements of the ceiling. For fastening anchors or dowels, screws and vibration isolation mounting assemblies. The suspensions mounted rails acoustic profiles. Length adjustable by 10 mm smaller than the size of the room. The space between the rails is filled with sound-absorbing plates. Completion of work — the fastening of sheets of drywall to the profiles.

The ceiling on fibropapilloma suspensions

The design uses building suspensions for suspended ceiling with built-in anti-vibration blocks. The product prevents the spread of impact noise from the floor to the metal profile of ceiling. Fibropapilloma ceiling height is 170-190 mm, so they are set if the distance from floor to ceiling of 3 m.

The order of installation:

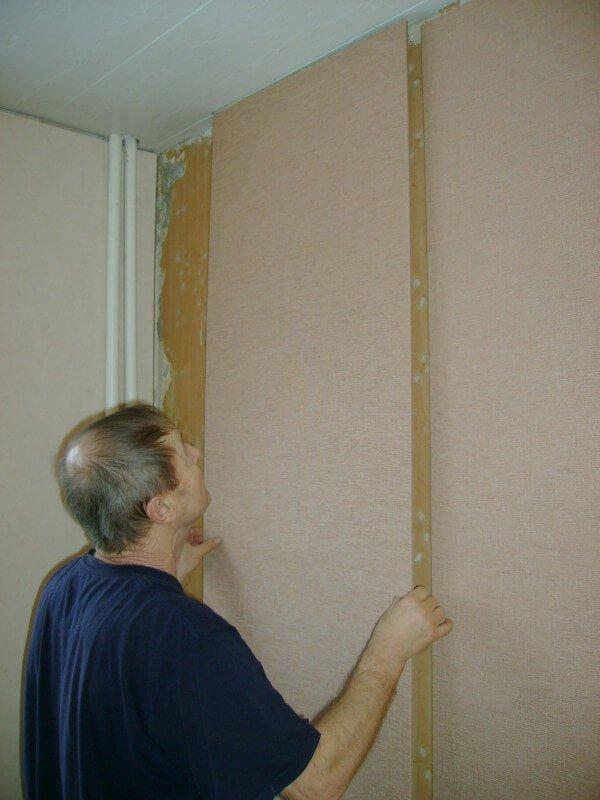

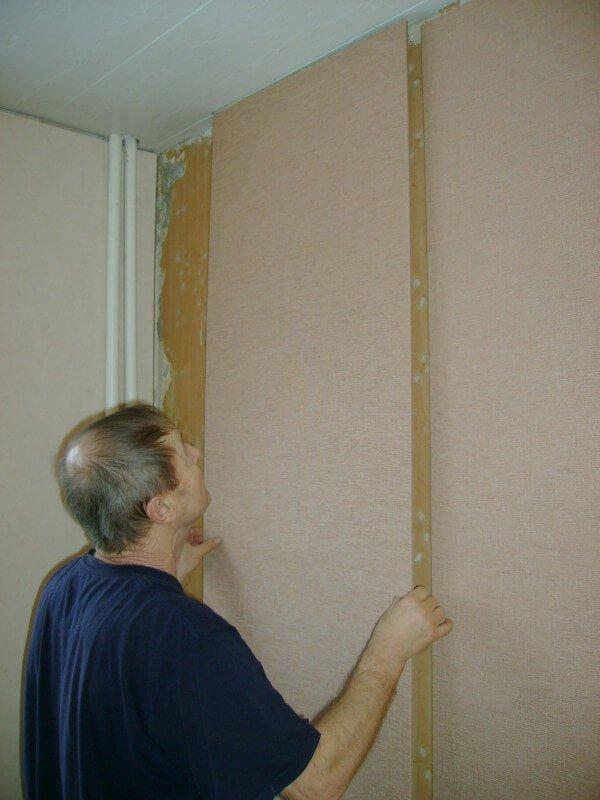

To the ceiling attach vibrapods according to the instructions. To vibrapods is fixed with metal profiles. Fill the space between the profiles with mineral wool for increased sound insulation. Profile attached to the special insulating panel. Panels are fixed to the first thin fabric, for example, the Wolf flees, and then drywall. Between them remains a small gap, which improves sound insulation. Noise insulation wallsof Plasterboard structuresattached To the wall frame profile, departing a couple of inches from the surface. The slit is placed a sound-insulating elements made of rubber or cork.

Frame filled with sound-insulating mats.

The last step is fastening the drywall to the profile.

The main drawback of the method — each design reduces the dimensions of the room 10 cm

Decorative soundproof panelsound insulation properties of the finished panels similar to drywall products. It's a light product, their weight does not exceed 4 lbs. When mounted is fixed to a flat surface. If necessary, on the wall to make a crate and put the slats in a single plane. To the sheathing panels are attached with liquid nails, and are joined together by the method of "tongue in groove". After mounting the decoration of the walls is not required — the surface looks very beautiful thanks to textile or paper finishing. In this way, it is recommended to isolate the apartment is fully and not one wall.

Rolled insulation wallsRoll insulator is fixed to the surface of the Wallpaper glue. The noise level after the work was reduced only by 60 percent. This method is used, for example, during a stay in a rented apartment.

Elimination of construction defectsto Reduce the noise from neighbors is possible if you follow simple recommendations for fixing defects builders.

Electrical outlets and boxesIn apartment buildings to install electrical accessories sometimes penetrate the walls of the through holes. The result is a channel between the neighboring apartments through which noise enters the room.

The problem is solved in the following way:

Remove the power outlet and mounting box. Measure the hole diameter and cut to size a strip of mineral wool, asbestos cloth or cardboard basalt. Install the gasket into the opening until the stop seal putty. It is forbidden to use foam for this purpose because of the high Flammability. Assemble the socket. Similarly, close up the holes for the mounting (terminal) electrical box. They are closed with plastic caps and are under the Wallpaper, you can find them, if you knock in the places of their proposed installation.

The standpipesFor the heating and water pipes through floors are used damping pipe lengths. They have a diameter larger than the diameter of the pipe, so between them is a gap that should be filled with absorbent material and be sealed from the outside with putty. To check the quality of installation remove the top cement layer and inspect the casing. If there are voids between the sleeve and the pipe, clear the gap of debris as deep as possible. Wrap the pipe sound insulation material and seal the joint with cement mortar. From the outside the junction of the cover with silicone sealant.

The joints between the ceiling and wallsIf the house is old, between the slabs and walls can cause cracks. They are not visible under the Wallpaper, and do not spoil the interior of the room, but the sounds are missing. Cracks should be filled with a filler or fluff on top of acrylic sealant.

To ensure that 100 percent soundproofing is impossible, but this is not necessary. Enough that the noise decreased, at least until the non-irritating level. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: //www.rmnt.ru/story/isolation/1061454.htm