686

As we have for the science Museum made a Tesla coil

In 2016 I was asked to participate in the project to create a powerful Tesla coil for the science Museum in his hometown. To refuse would be to betray their ideals and their own children that adore science experiments. Further, not only the description of the design of the resulting device but also a little about men's love of science, and enthusiastic about the birth and implement social projects.

The backgroundIs a story about people. Who doesn't love stories about people, can safely skip this section.

First, a little about yourself. My name is Artem. Now I work as a designer in a private firm, but by education, a physicist, and methods of teaching physics to children is my passion. Four years ago, I was fully immersed in science, he worked in “the Laboratory methodology of physics teaching” University, conducted refresher courses for teachers across the region, was a co-host of the circle “Young physicists” for children from 5 years and also worked as a teacher of physics and developed the author's website.

It was then in Ukraine for the first time began to conduct Scientific picnics. This is a great event for the popularization of science, when universities, laboratories, research centers come to the area together with the physical exhibits, liquid nitrogen, skeletons, and mannequins, microscopes, telescopes, rare insects and bats. In General, everyone exposes what has been and what will be of interest to others. Of course, in the Science picnic took an active part and a lab, a school and a club where I worked.

There I met one of the organizers of the picnic. This guy was dreaming about the science Museum for our city, and convinced me that if I didn't give up and be active, all will succeed.

So it happened, the Scientific picnic was a great success, on the basis of this positive result, the University decided to give the green light to the team of Sergey and generously gave the Museum some of the rooms impressive square.

This was probably the most romantic time. With almost no funding, the attempt to make of the destroyed premises of the science Museum for a month or two it looked crazy. But he was not discouraged, he rushed like a meteor, patching holes in the floor, draped the walls with no repair tissue, making the walls and supports for future exhibits. Sergey showed amazing determination and will, and also remarkable organisational abilities. Our laboratory, like many others, helped the project demonstration devices and ideas of budget, but fascinating exhibits.

The Museum successfully opened, and I went with my wife and children in Montenegro. There I also organized a group on astronomy and physics, but the main place of work has become the design Department.

Last year I returned to Ukraine. He gave me a tour of the updated Museum. In two years, the Museum made repairs several times increased Expo base and significantly expanded footprint. Was incredibly pleased to discover running one of the demonstration devices — “optical bench”, which your own hands have gathered since the dawn of the project.

Sergei told about the desire to procure for the Museum the “Tesla coil”, he not only found the seller, but agreed with a great company “X” to sponsor the project and even managed to get the money. However, immediately before the sale, the seller decided to increase the price twice. Of course, communication on this has been completed. But Sergei found himself in an unenviable position.

Some time later Sergey called me and said that he found a guy who has already collected several small Tesla coils, and is willing to try to assemble the coil larger. But he needs help with the mechanics. Unobtrusive I was invited to join the project, without the right to refuse.

Had a meeting with this “celastrales”, which, incidentally, is also named Sergey. It's obvious that it was some kind of freak, who mania to Tesla coils, and a fixed idea — a big Coil. But as soon as we began to discuss the project, send discrepancies to be presented (I think here you need to insert “me”). The interviewer began to consistently present the design of the instrument, not repeated, not saying anything extra. All terms were used correctly and physical phenomena were given correct interpretation. All the questions sounded clear and logical answers. It turned out that I communicate adequate teacher known technical University that are really keen on Tesla coils.

Sergey turned out to be an owner of such valuable qualities as thoroughness. That was won deep respect. He had a long and carefully prepared his workplace, picked up an advance tool and upgraded, all the contacts he always, absolutely always, carefully ladel. If in a hurry to perform at a quality connection, then Sergei would say nothing, and then quietly take it in and fix it. It may seem that such scruples are unnecessary, but in fact it saves tremendous amount of time. Indeed, for the entire period of operation we have never encountered an error of incorrect Assembly. To avoid confusion among Sergeyev, we will call him Sergei A., and the first — Sergey V.

What is a Tesla coil?I asked Sergei A. (the author of the coils) sobstvennolichno to tell you about the coil. All text in this section belongs to him:

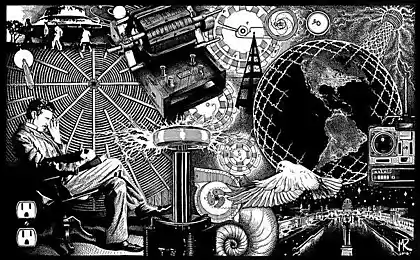

In the late 19th and early 20th centuries, Nikola Tesla experimented with high voltage high frequency resonant transformers without ferromagnetic core (air transformer). This kind of transformer was subsequently named the Tesla coil or Tesla coil.

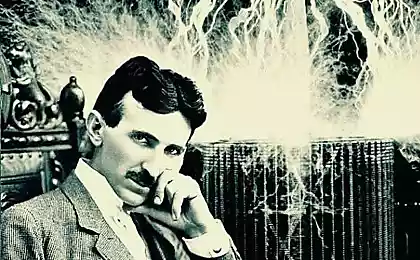

Currently, the Tesla transformer is more a toy for those who enjoy DIY and want to have in your collection something more than a device having a certain field of application. Rarely in one simple design can combine many physical phenomena. Besides, you will not find such a person, which the Tesla coil will not be able to surprise their electrical discharges.

Why you need a Tesla coil? First and foremost, for educational purposes. Because here addressed a variety of topics:

As a result of the voltage resonance in the primary circuit the oscillation amplitude will increase in this part of the energy will be transferred to the secondary winding of the transformer (which is characterized by the coupling coefficient between the windings), the latter together with a metal toroid also form a resonant circuit.

Then the process can be described similar to the rocking of the swing: if you push the swing at the right time, then soon they will fly up very high, this will be the voltage output of a Tesla coil. When the voltage becomes so high that the air for him ceases to be an insulator, all the stored energy forms an electrical discharge or streamer.

For many years, the design of transformers Tesla has been amended, so that today there are several topologies, devices with similar working principle, thus distinguished on a component level.

SGTC (Spark Gap Tesla Coil) – Tesla coil on the spark gap. Is a classic execution used by Nikola Tesla. As a key element uses two contacts of arbitrary shape, between which occurs an electrical discharge. Structurally, consists of only 6 elements and often works the first time. However, in low-power versions to wait for the beautiful bits do not have to, but make out light bulb in the distance or admire the glow of coronary — please.

The derivative of this topology is the view of ARSGTC (Asynchronous Rotary Spark Gap Tesla Coil), where the commutating switch applies rotary motor, normally open contacts, and quickly tearing the formed electric arc that produces the greatest length of the discharges at relatively low input power. This was to take us to the repetition.

VTTC (Vacuum Tube Tesla Coil) – Tesla transformer for vacuum tubes. Requires working with high anode voltages and is not recommended for beginners.

SSTC (Solid State Tesla Coil) – Tesla coil, which are used as keys of semiconductor components. The most common use of MOSFET transistors or IGBT (not to be confused with LGBT). Through the use of modern component base coils of this type can be easily operated, modulating the frequency of lightning external source of signal, for example music.

DRSSTC (Dual Resonant SSTC) – Tesla coil double resonant circuit. The topology is much more complicated to manufacture than its predecessor, but it kompensiruet improved ratio of length of the discharge to the length of the secondary winding.

QCWDRSSTC (Quasi-Continuous-Wave DRSSTC) is a variant of the Tesla coil double resonant circuit, but is capable of producing characteristic only for this topology, long straight zipper, sometimes more than 10 times the length of the secondary winding.

There's bipolar Tesla coil, but more on that another time.

As you can see, Tesla coils there are on any "taste and color", and anyone can choose the way you want. In recent years the market has tried to meet the increased demand of radio Amateurs and experimenters for transformers, Tesla, and now even on AliExpress, there are sets of them at home you can assemble a working device.

Not as advertising, but it is worth mentioning a group of enthusiasts who in early 2013 launched the company on Kickstarter (which at the time covered) and successfully collected the required amount, up to the present time continue to work on the project, called OneTesla. What differentiates it from other projects — so it's open documentation and diagrams, where anyone can follow the instructions to assemble at home music coil DRSSTC topology. Guided by instructions from the site OneTesla, I gathered my first working coil.

I want to say that to make a working Tesla coil is very simple, but make such that it was not ashamed to show, is still very expensive and time consuming.

Our selection of "Old school"For lovers of numbers — a brief technical description of our exhibit from Sergey A.

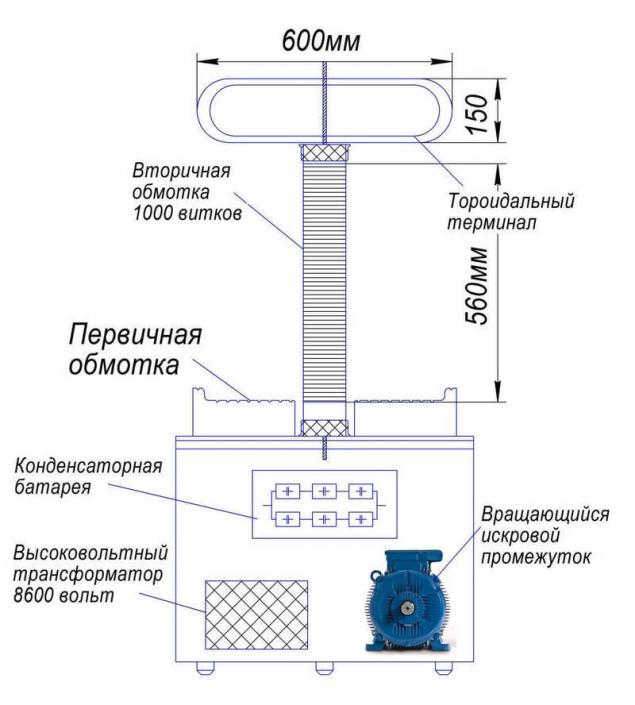

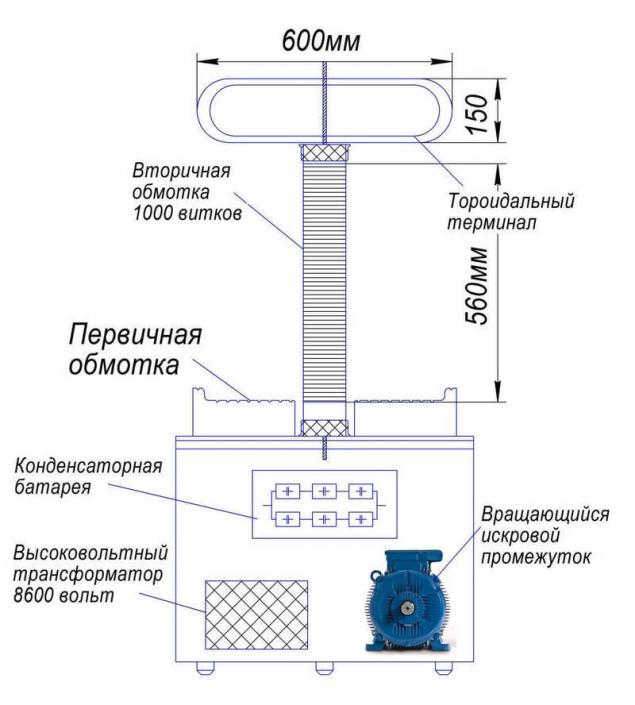

For the operation of the Tesla coil needs high voltage power supply, and to save time on winding your own transformer, it was decided to use the ready. Thus, in the power circuit involved 4 transformers from microwave ovens in series connection with a mid-point that converts the network 220 volts in voltage 8600 volts.

To ensure their cooling and to avoid inter-turn breakdown of all 4 transformers were immersed in synthetic motor oil.

As the production capacity used battery from 5 to 9 branches of series-connected capacitors (MMC), that is 45 capacitors of 0.1 µf and a voltage of 2 kV was given capacitance 55 nF with a voltage of 18 kV. And used switching wire gauge 8 AWG, copper tube with diameter of 6.35 mm as a primary winding with 6 ½ turns. 1000 turns of copper wire with a cross section of 0.5 mm in the ventilation pipe with a diameter of 10 cm forms a secondary coil with a winding length of 56 see the Toroid is made of aluminum vent pipe with a diameter of 11 cm.

The calculated resonant frequency of the primary circuit, and then confirmed with the pulse generator and frequency counter was 220 kHz. The resonant frequency of the secondary circuit for the calculation and the measurements is about 250 kHz, but at the time of emergence of a streamer due to the electrical capacitance of the discharge, the oscillation frequency decreases, and there is a contact resonance between the primary and secondary circuits, which leads to an increase of the length of the lightning.

Now, about the mechanical component, the Available budget did not allow much room to roam. The number of milling and turning work had to be minimized. All non-critical parts are made by our own hands.

Disc pulper was made of textolite with a thickness of 8 mm. disk is 6 contacts that close the gap. The disc is on the axis of the two-pole asynchronous motor with power of 0.37 kW. The engine speed is 2800 rpm./min. Given that one turnover on 6-circuits, we get 280 circuits per second.

In the Internet you can find these maniacs who put the disc of the arrestor to the shaft of the angle grinder:

Such decisions its simplicity, but it is not compatible with this concept, as safety. Sander securely attached to the base with a clamp around the handle. The electrodes on the disk overheated, as they have little time and cooling area. The disc rotates with a frequency of between 4,000 and 6,000 rpm./min! This delicate balance is easy to break, and then the hot electrodes, as the shrapnel will scatter in arbitrary directions. Please, use angle grinding machine for the intended purpose only!

The primary coil is made in the form of a spiral of copper tubes diameter of ¼ ” to these tubes typically freon is circulated between the air conditioning units. The geometry of the coil is very important, it depends on the inductance, and as a result, the frequency of the oscillating circuit. To form strictly consistent with the design, was designed a simple mounting of the four pillars. The support was made from a sheet of PVC with CNC milling.

Good exhibit, secure the exhibit

Of course, the Tesla coil is a dangerous device correctly even say deadly. Consider all the factors according to their importance.

“In operation of the Tesla transformer was observed a certain elegance, magical appeal, so that it would show everyone and not show anyone, so, following his instinctive desire to protect the coil from exposure to the outside world, it was decided to place it in a room with no Windows, inside a metal cage with a door on the lock and behind a wall of thick glass.”

How we got to UMBRELLA INC

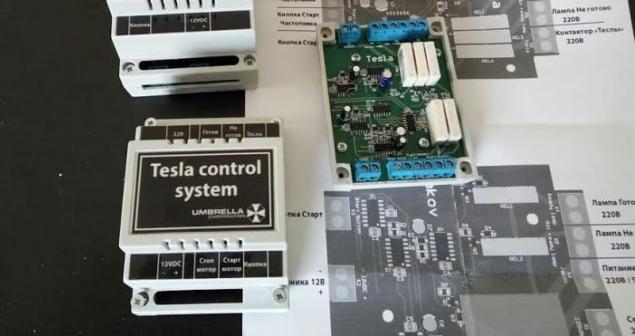

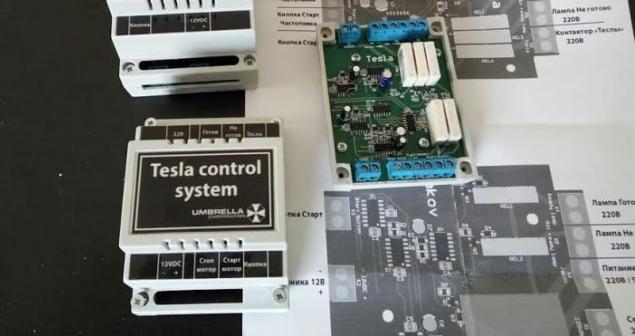

When you turn the coil needs to run a certain sequence. First should turn on and enter the operating mode of the motor, and only after that can be powered on the primary winding. We needed a control unit, which would provide a simple starting installation, and perform a number of other algorithms. To assemble the device “on the knee” were not even considered. Formulated the TOR and asked for help in one design Bureau “Y”. Our order for them was small and not interesting, but, given the social orientation of the project and the small amount of work they agreed to do it free of charge. We only paid components and the manufacture of circuit boards at the factory.

When the work was completed, electronics, cute, smiling, handed me the box with the boards. Instead of a company logo, we found a modest inscription “UMBRELLA”. The firm refused to PR, and electronics from our thanks.

Start-up and commissioning, Everything went according to plan. All parts were manufactured and on their designated seats with no surprises. Well, almost no surprises. The fact that we had a desire to adjust the frequency of interruptions on dischargers. For this purpose the motor was purchased chastotnik of the national production. This is chastotnik took a few days of work, we were involved in a funny, sad and cautionary tale at the same time. Morality boiled down to the fact that it is better not to use the frequency controllers of the national production. If you have any queries in the comments, chastotnik will be dedicated a separate post with a review and photos of the autopsy.

After the rejection of frequency control, the machine worked at the first start. Theoretical calculations Sergey has fully justified itself. We cut the floor extra loop primary coil and hit the resonance. All nodes worked full-time.

Ultraviolet lightning caressed our faces, loud rumblings were pleasing to the heart. The smell of ozone spread throughout the room with an area of 150 m2. We knew it was time to finish the job. Following the launches we decided to make our already designed room, with all specified security measures. We were only waiting for the completion of construction.When the overhaul was completed, we had only two weeks to install the Tesla coil, perform all connections and test the system for reliability. It was a small term, considering that two of the three team members had a permanent place of work outside the Museum of science, and to perform any operation alone was impossible.

We moved the equipment, did all the connections, re-checked everything, gave power to boards of management, include all machines, solemnly pressed the button and...

...and nothing happened. Nothing at all. Troubleshooting found that one of the phases has a voltage of 60 V instead of 220 V! Fortunately, we had access to all three phases and were able to quickly reconnect. For us the issue was resolved quickly, but in the building where is the Museum of science, a third of the equipment was not working more than a week.

The real challenges were waiting for us in the control unit of the Tesla coil. Despite the fact that all inputs and outputs to the unit was isolated and power to the spark gap was fed by a separate phase as soon as the discharger slipped the first spark, the control unit went crazy. He or right off the coil, or turn it off altogether, or turn off the engine. The root of the evil lay in the high-frequency noise that went from the coil through the wires back to the grid. The impulse was so strong that the induced interference to the adjacent wires. In previous tests we were laying out the wires so that they were going to remove one from the other. Here, according to the project designers, they walked through the common pipes. We had to make changes to the project. We took out the control Board from the General Board in separate Cabinet ground. But it changed nothing. Here and started dancing with a tambourine.

In finding solutions we've tried everything, even resorted to such homeopathic remedies as the installation of ferrite rings and suppressor. Time passed, and the tension increased.

Periodically I'd take my oldest six year old son with me. While we worked, he had fun in the Museum. Often I went, and most of the work the guys have done themselves. Everyone was sympathetic to my marital status.

At some point we were joined by another enthusiast, who was also named Sergey. This guy was a University student, but very intelligent. The emergence of the third Sergey unexpectedly positive impact on the efficiency of our company. With his participation we have established the root cause of the fault. The weak link was the input from the start button, the only button that needs to press the visitor. We once again changed the project and held the cable from the buttons to the control unit in a separate tube. In addition, we rewired some of the components on the Board. Changed the values of pullup resistors, and one resistor from the power suppression of chattering of the contact. This measure has worked, and the problem we fixed. With quiet soul we met the New Year together at my house.

The result

The unveiling took place on 4 January, since he was a staff works and entertains visitors. Appeared in the media pathetic headlines: "Scientists have reconstructed the coil Nikola Tesla", "has Earned the biggest Tesla coil in Europe," "In the center of the X there was a room of high energy", "Scientists have invented a cure for cancer", etc. As a designer, I don't feel very proud to draft, I think that for many readers it is clear that from an engineering point of view, it is quite a simple device, made to the same with some flaws.

But very nice to remember the process: our meetings after work, discussing the concepts for the cheap buffet pizza, first run, hard struggle with failure and victory. Somehow, these memories intersect with different events from early childhood: in 4 years did short circuit in the apartment, sticking the pin in the socket, how "fixed" the VCR of his brother, both from lumber and nails built his airplane and tried to run it the first time took in hands a soldering iron. By implementing this little project, each of us managed to embody the dreams and aspirations of childhood. It makes me feel very warm and pleasant to the soul, and I want to share with you. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: geektimes.ru/post/285328/

The backgroundIs a story about people. Who doesn't love stories about people, can safely skip this section.

First, a little about yourself. My name is Artem. Now I work as a designer in a private firm, but by education, a physicist, and methods of teaching physics to children is my passion. Four years ago, I was fully immersed in science, he worked in “the Laboratory methodology of physics teaching” University, conducted refresher courses for teachers across the region, was a co-host of the circle “Young physicists” for children from 5 years and also worked as a teacher of physics and developed the author's website.

It was then in Ukraine for the first time began to conduct Scientific picnics. This is a great event for the popularization of science, when universities, laboratories, research centers come to the area together with the physical exhibits, liquid nitrogen, skeletons, and mannequins, microscopes, telescopes, rare insects and bats. In General, everyone exposes what has been and what will be of interest to others. Of course, in the Science picnic took an active part and a lab, a school and a club where I worked.

There I met one of the organizers of the picnic. This guy was dreaming about the science Museum for our city, and convinced me that if I didn't give up and be active, all will succeed.

So it happened, the Scientific picnic was a great success, on the basis of this positive result, the University decided to give the green light to the team of Sergey and generously gave the Museum some of the rooms impressive square.

This was probably the most romantic time. With almost no funding, the attempt to make of the destroyed premises of the science Museum for a month or two it looked crazy. But he was not discouraged, he rushed like a meteor, patching holes in the floor, draped the walls with no repair tissue, making the walls and supports for future exhibits. Sergey showed amazing determination and will, and also remarkable organisational abilities. Our laboratory, like many others, helped the project demonstration devices and ideas of budget, but fascinating exhibits.

The Museum successfully opened, and I went with my wife and children in Montenegro. There I also organized a group on astronomy and physics, but the main place of work has become the design Department.

Last year I returned to Ukraine. He gave me a tour of the updated Museum. In two years, the Museum made repairs several times increased Expo base and significantly expanded footprint. Was incredibly pleased to discover running one of the demonstration devices — “optical bench”, which your own hands have gathered since the dawn of the project.

Sergei told about the desire to procure for the Museum the “Tesla coil”, he not only found the seller, but agreed with a great company “X” to sponsor the project and even managed to get the money. However, immediately before the sale, the seller decided to increase the price twice. Of course, communication on this has been completed. But Sergei found himself in an unenviable position.

Some time later Sergey called me and said that he found a guy who has already collected several small Tesla coils, and is willing to try to assemble the coil larger. But he needs help with the mechanics. Unobtrusive I was invited to join the project, without the right to refuse.

Had a meeting with this “celastrales”, which, incidentally, is also named Sergey. It's obvious that it was some kind of freak, who mania to Tesla coils, and a fixed idea — a big Coil. But as soon as we began to discuss the project, send discrepancies to be presented (I think here you need to insert “me”). The interviewer began to consistently present the design of the instrument, not repeated, not saying anything extra. All terms were used correctly and physical phenomena were given correct interpretation. All the questions sounded clear and logical answers. It turned out that I communicate adequate teacher known technical University that are really keen on Tesla coils.

Sergey turned out to be an owner of such valuable qualities as thoroughness. That was won deep respect. He had a long and carefully prepared his workplace, picked up an advance tool and upgraded, all the contacts he always, absolutely always, carefully ladel. If in a hurry to perform at a quality connection, then Sergei would say nothing, and then quietly take it in and fix it. It may seem that such scruples are unnecessary, but in fact it saves tremendous amount of time. Indeed, for the entire period of operation we have never encountered an error of incorrect Assembly. To avoid confusion among Sergeyev, we will call him Sergei A., and the first — Sergey V.

What is a Tesla coil?I asked Sergei A. (the author of the coils) sobstvennolichno to tell you about the coil. All text in this section belongs to him:

In the late 19th and early 20th centuries, Nikola Tesla experimented with high voltage high frequency resonant transformers without ferromagnetic core (air transformer). This kind of transformer was subsequently named the Tesla coil or Tesla coil.

Currently, the Tesla transformer is more a toy for those who enjoy DIY and want to have in your collection something more than a device having a certain field of application. Rarely in one simple design can combine many physical phenomena. Besides, you will not find such a person, which the Tesla coil will not be able to surprise their electrical discharges.

Why you need a Tesla coil? First and foremost, for educational purposes. Because here addressed a variety of topics:

- in statics – the study of the theory, familiarity with electrical components, read schematics, learn how to use a multimeter and use simulations of electrical circuits, finally, to understand the difference between inductance and capacitance;

- dynamic electrical oscillations, voltage resonance energy transfer, ionization, nature of plasma, the properties of electromagnetic radiation, the impact of current on a human being.

As a result of the voltage resonance in the primary circuit the oscillation amplitude will increase in this part of the energy will be transferred to the secondary winding of the transformer (which is characterized by the coupling coefficient between the windings), the latter together with a metal toroid also form a resonant circuit.

Then the process can be described similar to the rocking of the swing: if you push the swing at the right time, then soon they will fly up very high, this will be the voltage output of a Tesla coil. When the voltage becomes so high that the air for him ceases to be an insulator, all the stored energy forms an electrical discharge or streamer.

For many years, the design of transformers Tesla has been amended, so that today there are several topologies, devices with similar working principle, thus distinguished on a component level.

SGTC (Spark Gap Tesla Coil) – Tesla coil on the spark gap. Is a classic execution used by Nikola Tesla. As a key element uses two contacts of arbitrary shape, between which occurs an electrical discharge. Structurally, consists of only 6 elements and often works the first time. However, in low-power versions to wait for the beautiful bits do not have to, but make out light bulb in the distance or admire the glow of coronary — please.

The derivative of this topology is the view of ARSGTC (Asynchronous Rotary Spark Gap Tesla Coil), where the commutating switch applies rotary motor, normally open contacts, and quickly tearing the formed electric arc that produces the greatest length of the discharges at relatively low input power. This was to take us to the repetition.

VTTC (Vacuum Tube Tesla Coil) – Tesla transformer for vacuum tubes. Requires working with high anode voltages and is not recommended for beginners.

SSTC (Solid State Tesla Coil) – Tesla coil, which are used as keys of semiconductor components. The most common use of MOSFET transistors or IGBT (not to be confused with LGBT). Through the use of modern component base coils of this type can be easily operated, modulating the frequency of lightning external source of signal, for example music.

DRSSTC (Dual Resonant SSTC) – Tesla coil double resonant circuit. The topology is much more complicated to manufacture than its predecessor, but it kompensiruet improved ratio of length of the discharge to the length of the secondary winding.

QCWDRSSTC (Quasi-Continuous-Wave DRSSTC) is a variant of the Tesla coil double resonant circuit, but is capable of producing characteristic only for this topology, long straight zipper, sometimes more than 10 times the length of the secondary winding.

There's bipolar Tesla coil, but more on that another time.

As you can see, Tesla coils there are on any "taste and color", and anyone can choose the way you want. In recent years the market has tried to meet the increased demand of radio Amateurs and experimenters for transformers, Tesla, and now even on AliExpress, there are sets of them at home you can assemble a working device.

Not as advertising, but it is worth mentioning a group of enthusiasts who in early 2013 launched the company on Kickstarter (which at the time covered) and successfully collected the required amount, up to the present time continue to work on the project, called OneTesla. What differentiates it from other projects — so it's open documentation and diagrams, where anyone can follow the instructions to assemble at home music coil DRSSTC topology. Guided by instructions from the site OneTesla, I gathered my first working coil.

I want to say that to make a working Tesla coil is very simple, but make such that it was not ashamed to show, is still very expensive and time consuming.

Our selection of "Old school"For lovers of numbers — a brief technical description of our exhibit from Sergey A.

For the operation of the Tesla coil needs high voltage power supply, and to save time on winding your own transformer, it was decided to use the ready. Thus, in the power circuit involved 4 transformers from microwave ovens in series connection with a mid-point that converts the network 220 volts in voltage 8600 volts.

To ensure their cooling and to avoid inter-turn breakdown of all 4 transformers were immersed in synthetic motor oil.

As the production capacity used battery from 5 to 9 branches of series-connected capacitors (MMC), that is 45 capacitors of 0.1 µf and a voltage of 2 kV was given capacitance 55 nF with a voltage of 18 kV. And used switching wire gauge 8 AWG, copper tube with diameter of 6.35 mm as a primary winding with 6 ½ turns. 1000 turns of copper wire with a cross section of 0.5 mm in the ventilation pipe with a diameter of 10 cm forms a secondary coil with a winding length of 56 see the Toroid is made of aluminum vent pipe with a diameter of 11 cm.

The calculated resonant frequency of the primary circuit, and then confirmed with the pulse generator and frequency counter was 220 kHz. The resonant frequency of the secondary circuit for the calculation and the measurements is about 250 kHz, but at the time of emergence of a streamer due to the electrical capacitance of the discharge, the oscillation frequency decreases, and there is a contact resonance between the primary and secondary circuits, which leads to an increase of the length of the lightning.

Now, about the mechanical component, the Available budget did not allow much room to roam. The number of milling and turning work had to be minimized. All non-critical parts are made by our own hands.

Disc pulper was made of textolite with a thickness of 8 mm. disk is 6 contacts that close the gap. The disc is on the axis of the two-pole asynchronous motor with power of 0.37 kW. The engine speed is 2800 rpm./min. Given that one turnover on 6-circuits, we get 280 circuits per second.

In the Internet you can find these maniacs who put the disc of the arrestor to the shaft of the angle grinder:

Such decisions its simplicity, but it is not compatible with this concept, as safety. Sander securely attached to the base with a clamp around the handle. The electrodes on the disk overheated, as they have little time and cooling area. The disc rotates with a frequency of between 4,000 and 6,000 rpm./min! This delicate balance is easy to break, and then the hot electrodes, as the shrapnel will scatter in arbitrary directions. Please, use angle grinding machine for the intended purpose only!

The primary coil is made in the form of a spiral of copper tubes diameter of ¼ ” to these tubes typically freon is circulated between the air conditioning units. The geometry of the coil is very important, it depends on the inductance, and as a result, the frequency of the oscillating circuit. To form strictly consistent with the design, was designed a simple mounting of the four pillars. The support was made from a sheet of PVC with CNC milling.

Good exhibit, secure the exhibit

Of course, the Tesla coil is a dangerous device correctly even say deadly. Consider all the factors according to their importance.

- If you think that we should be afraid of six-foot lightning that fly in all directions, you know, this is just the beginning. The real danger is the primary winding, so plain a coil which is energized To 8600 and is ready to share its current with the force of hundreds of milliamps. Accidentally touch her — a sure way to heaven. Lightning can also cause significant harm to humans, but their danger is much less.

- It is also worth mentioning that the Tesla coil generates a powerful electromagnetic field. This field is capable of at a distance of several meters to light a gas discharge lamp and in a radius of more than ten meters incapacitate sensitive to electrical interference. Thus, even at considerable distances, the device poses a real threat to people with pacemakers.

- In addition, the process releases massive amounts of ozone, Wikipedia says that ozone, a highly toxic gas possessing oxidizing properties, which can lead to premature death. The good news is that ozone effectively kills mold and bacteria.

- Do not forget that lightning Shine not only visible light but also ultraviolet light, which is not particularly useful for the eyes.

- Also be aware that the installation generates noise (about 100 DB at a distance of 3 meters). The noise causes discomfort, but also can frighten the child.

- Work exhibit only in the presence of a person familiar with the TB (the leading).

- Multiple machines, breakers and magnetic contactor. To the coil was energized, must be fulfilled a number of conditions, in particular, the signal from the fuse box, the key to which has only the leading. But to de-energize the unit can even have a visitor. In addition, the installation disables itself by the time relay 40 C.

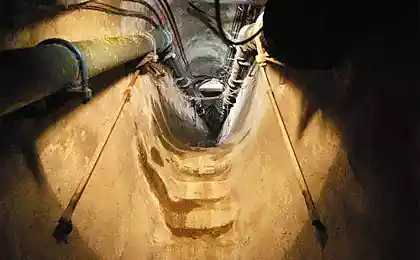

- The installation was placed in a Faraday cage. The cell has its own ground and is lockable. This tool protects against lightning electromagnetic field screens, and also serves as a trusted fence.

- Partition of tempered glass thickness of 10 mm. Glass absorbs the ultraviolet light and, in conjunction with compulsory hood prevents the ingress of ozone in the hall with visitors.

- The glass acts as a sound-proof partitions, it significantly (-10 DB) reduces the sound pressure level. However, for the youngest visitors was further ordered noise-canceling headphones.

“In operation of the Tesla transformer was observed a certain elegance, magical appeal, so that it would show everyone and not show anyone, so, following his instinctive desire to protect the coil from exposure to the outside world, it was decided to place it in a room with no Windows, inside a metal cage with a door on the lock and behind a wall of thick glass.”

How we got to UMBRELLA INC

When you turn the coil needs to run a certain sequence. First should turn on and enter the operating mode of the motor, and only after that can be powered on the primary winding. We needed a control unit, which would provide a simple starting installation, and perform a number of other algorithms. To assemble the device “on the knee” were not even considered. Formulated the TOR and asked for help in one design Bureau “Y”. Our order for them was small and not interesting, but, given the social orientation of the project and the small amount of work they agreed to do it free of charge. We only paid components and the manufacture of circuit boards at the factory.

When the work was completed, electronics, cute, smiling, handed me the box with the boards. Instead of a company logo, we found a modest inscription “UMBRELLA”. The firm refused to PR, and electronics from our thanks.

Start-up and commissioning, Everything went according to plan. All parts were manufactured and on their designated seats with no surprises. Well, almost no surprises. The fact that we had a desire to adjust the frequency of interruptions on dischargers. For this purpose the motor was purchased chastotnik of the national production. This is chastotnik took a few days of work, we were involved in a funny, sad and cautionary tale at the same time. Morality boiled down to the fact that it is better not to use the frequency controllers of the national production. If you have any queries in the comments, chastotnik will be dedicated a separate post with a review and photos of the autopsy.

After the rejection of frequency control, the machine worked at the first start. Theoretical calculations Sergey has fully justified itself. We cut the floor extra loop primary coil and hit the resonance. All nodes worked full-time.

Ultraviolet lightning caressed our faces, loud rumblings were pleasing to the heart. The smell of ozone spread throughout the room with an area of 150 m2. We knew it was time to finish the job. Following the launches we decided to make our already designed room, with all specified security measures. We were only waiting for the completion of construction.When the overhaul was completed, we had only two weeks to install the Tesla coil, perform all connections and test the system for reliability. It was a small term, considering that two of the three team members had a permanent place of work outside the Museum of science, and to perform any operation alone was impossible.

We moved the equipment, did all the connections, re-checked everything, gave power to boards of management, include all machines, solemnly pressed the button and...

...and nothing happened. Nothing at all. Troubleshooting found that one of the phases has a voltage of 60 V instead of 220 V! Fortunately, we had access to all three phases and were able to quickly reconnect. For us the issue was resolved quickly, but in the building where is the Museum of science, a third of the equipment was not working more than a week.

The real challenges were waiting for us in the control unit of the Tesla coil. Despite the fact that all inputs and outputs to the unit was isolated and power to the spark gap was fed by a separate phase as soon as the discharger slipped the first spark, the control unit went crazy. He or right off the coil, or turn it off altogether, or turn off the engine. The root of the evil lay in the high-frequency noise that went from the coil through the wires back to the grid. The impulse was so strong that the induced interference to the adjacent wires. In previous tests we were laying out the wires so that they were going to remove one from the other. Here, according to the project designers, they walked through the common pipes. We had to make changes to the project. We took out the control Board from the General Board in separate Cabinet ground. But it changed nothing. Here and started dancing with a tambourine.

In finding solutions we've tried everything, even resorted to such homeopathic remedies as the installation of ferrite rings and suppressor. Time passed, and the tension increased.

Periodically I'd take my oldest six year old son with me. While we worked, he had fun in the Museum. Often I went, and most of the work the guys have done themselves. Everyone was sympathetic to my marital status.

At some point we were joined by another enthusiast, who was also named Sergey. This guy was a University student, but very intelligent. The emergence of the third Sergey unexpectedly positive impact on the efficiency of our company. With his participation we have established the root cause of the fault. The weak link was the input from the start button, the only button that needs to press the visitor. We once again changed the project and held the cable from the buttons to the control unit in a separate tube. In addition, we rewired some of the components on the Board. Changed the values of pullup resistors, and one resistor from the power suppression of chattering of the contact. This measure has worked, and the problem we fixed. With quiet soul we met the New Year together at my house.

The result

The unveiling took place on 4 January, since he was a staff works and entertains visitors. Appeared in the media pathetic headlines: "Scientists have reconstructed the coil Nikola Tesla", "has Earned the biggest Tesla coil in Europe," "In the center of the X there was a room of high energy", "Scientists have invented a cure for cancer", etc. As a designer, I don't feel very proud to draft, I think that for many readers it is clear that from an engineering point of view, it is quite a simple device, made to the same with some flaws.

But very nice to remember the process: our meetings after work, discussing the concepts for the cheap buffet pizza, first run, hard struggle with failure and victory. Somehow, these memories intersect with different events from early childhood: in 4 years did short circuit in the apartment, sticking the pin in the socket, how "fixed" the VCR of his brother, both from lumber and nails built his airplane and tried to run it the first time took in hands a soldering iron. By implementing this little project, each of us managed to embody the dreams and aspirations of childhood. It makes me feel very warm and pleasant to the soul, and I want to share with you. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: geektimes.ru/post/285328/

Wise tips for choosing a place under the house

Commissioned the world's largest station for the capture of carbon dioxide