391

Quality control of concrete in the home

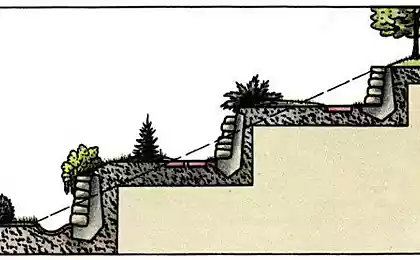

Buying a home with a concrete Foundation or the independent construction of concrete structures requires adequate control. Forms for concrete, grade and place fill key factors that should be considered during quality control.

Without sophisticated measuring equipment, it is possible with high accuracy to determine how well constructed concrete structure.

Mostly use in the construction of the grade of concrete from 15 and above. Violation in use of a particular design grade of concrete and the method and time the fill has serious consequences. To determine how well made design, will help simple test of concrete:

- Surface. Regardless of the place of use of the concrete product must have a smooth surface. If the structure was poured in the winter, that on its surface should not be patterns. If present, it means that during the pouring of the concrete was frozen. In turn, this reduces the strength of concrete up to 50-100 kg/cm2.

- Quality assurance. Using a simple hammer (500 g), it is possible to determine the strength of concrete structures. Tap with a hammer is not much on the product:

- a ringing sound and lack of damage proves the high quality and strength of concrete at the level of 200 kg/cm2;

- a ringing sound and prints from blows (in this case, the strength of the structure at the level of 150-200 kg/cm2);

- dull sound and lack of damage (the design may have serious internal defects);

- thud and traces of blows (poor-quality concrete construction with a strength of about 100 kg/cm2).

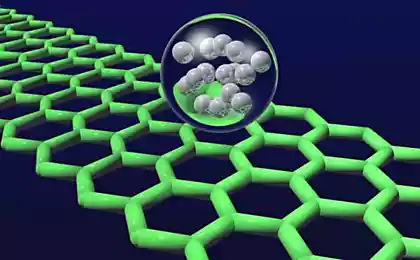

- Defects. The presence of a large number of pores indicates a poor seal. It is also a clear indicator of a poorly prepared concrete solution. If this design will constantly be on the street, the excessively high ability to absorb moisture will lead to its rapid destruction.

Source: /users/1077