460

What kind of future do we Shine?

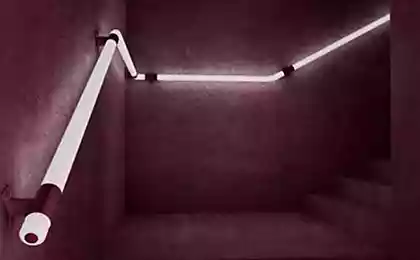

Led bulbs are already cheaper than incandescent bulbs when you take into account the electricity savings, but if the LEDs can reach to the level of prices, similar to incandescent lamps, there will be no excuses for the latter it is useless to waste electricity as heat instead of converting it to light.

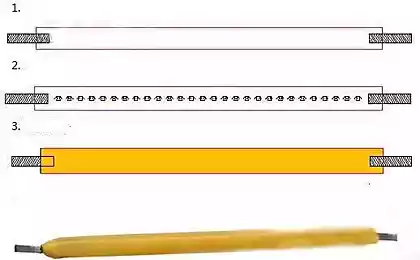

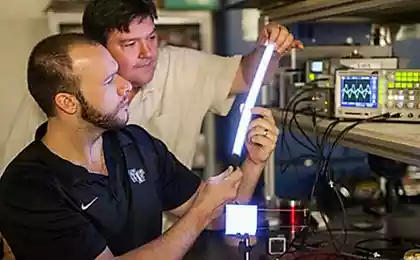

New development of the University scientists might allow you to replace the usual 4-5 layers, which is the usual led, a single layer of combined organic/inorganic materialthat can glow red, green or blue (or all three together for the white LEDs) and can be applied at room temperature and not at high temperatures necessary for traditional processes.

"LED the researchers used this material for about three years, although it had applied for solar panels for some time," says Jibin Yu (Zhibin Yu), Professor of industrial and manufacturing engineering. "Other groups are working with him to study the applicability of the LEDs, but they use several layers of material, making it expensive to process. We are the first group that published the work, which used a single layer of material."

Today, the LEDs need to be processed at a high temperature, expensive substrates to achieve high power, which generates a high price. Organic LEDs (OLED) are initially processed at low temperatures in a single layer, but with time, their production have started to use multiple layers and substrate of amorphous silicon to achieve adequate efficiency.

Yu and his colleague, researcher Junxiang Lee (Junqiang Li), saying that they managed to combine the best of both world, and then add some more. Their combined organic/inorganic material — ORGANOMETALLIC halide perovskite can be deposited at room temperature on a cheap glass substrate coated with indium and tin oxides and then subjected to fixation with a total of 140 degrees Fahrenheit (60 degrees Celsius) using a metal back plate.

"The structure of our new device only requires a mix of organic polymer with inorganic active instead of obtaining complex structures with many layers," says researcher, "so the process is inexpensive and very high-tech".

The researchers argue in their article that the energy saving LED lamps finally can be balanced relative to their cost by reducing the number of layers, namely just one use, instead of four or five.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: green-dom.info/

New development of the University scientists might allow you to replace the usual 4-5 layers, which is the usual led, a single layer of combined organic/inorganic materialthat can glow red, green or blue (or all three together for the white LEDs) and can be applied at room temperature and not at high temperatures necessary for traditional processes.

"LED the researchers used this material for about three years, although it had applied for solar panels for some time," says Jibin Yu (Zhibin Yu), Professor of industrial and manufacturing engineering. "Other groups are working with him to study the applicability of the LEDs, but they use several layers of material, making it expensive to process. We are the first group that published the work, which used a single layer of material."

Today, the LEDs need to be processed at a high temperature, expensive substrates to achieve high power, which generates a high price. Organic LEDs (OLED) are initially processed at low temperatures in a single layer, but with time, their production have started to use multiple layers and substrate of amorphous silicon to achieve adequate efficiency.

Yu and his colleague, researcher Junxiang Lee (Junqiang Li), saying that they managed to combine the best of both world, and then add some more. Their combined organic/inorganic material — ORGANOMETALLIC halide perovskite can be deposited at room temperature on a cheap glass substrate coated with indium and tin oxides and then subjected to fixation with a total of 140 degrees Fahrenheit (60 degrees Celsius) using a metal back plate.

"The structure of our new device only requires a mix of organic polymer with inorganic active instead of obtaining complex structures with many layers," says researcher, "so the process is inexpensive and very high-tech".

The researchers argue in their article that the energy saving LED lamps finally can be balanced relative to their cost by reducing the number of layers, namely just one use, instead of four or five.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: green-dom.info/

Calcaneal spur: 17 effective recipes of folk medicine

39 ideas that will help you to live, not to exist