690

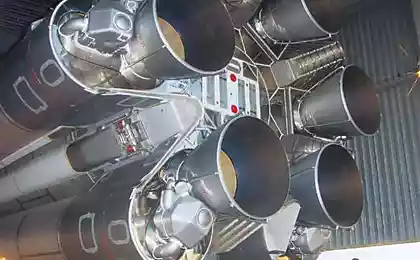

Toyota has developed a revolutionary eco-friendly rubber for engines

Toyota once again sets the standard in the automotive industry in the future. In May 2016 the company will be the first automaker in the world, is used to produce motor fittings innovative environmentally friendly synthetic rubber. Designed by Toyota based on vegetable raw materials innovative material called "biogidrin».

Creating "biogidrina" was the result of a joint project of Toyota, Zeon Corporation, and Sumitomo Riko Co., Ltd. Use of the new materials based on biological raw material can reduce by 20% associated with the production of cars CO2 emissions to the atmosphere. At this property "biogidrina" absolutely similar to those of rubber produced by petroleum-based, in terms of quality and mass production capabilities. The resulting developers Toyota biosynthetic rubber provides the highest durability of pipes and hoses due to its high resistance to the diffusion and resistance to heat.

In the future, Toyota plans to expand the use of innovative materials for the production of other elastic components exposed during operation to high loads such as brake hoses and fuel lines hoses.

The practical use of the new biosynthetic rubber for the production of mass-produced vehicles is an important step towards the realization of Toyota's environmental initiatives, published in October 2015. These initiatives, collectively referred Toyota Environmental Challenge 2050 is a comprehensive plan for a global solution to environmental problems by 2050.

Creating "biogidrina" was the result of a joint project of Toyota, Zeon Corporation, and Sumitomo Riko Co., Ltd. Use of the new materials based on biological raw material can reduce by 20% associated with the production of cars CO2 emissions to the atmosphere. At this property "biogidrina" absolutely similar to those of rubber produced by petroleum-based, in terms of quality and mass production capabilities. The resulting developers Toyota biosynthetic rubber provides the highest durability of pipes and hoses due to its high resistance to the diffusion and resistance to heat.

In the future, Toyota plans to expand the use of innovative materials for the production of other elastic components exposed during operation to high loads such as brake hoses and fuel lines hoses.

The practical use of the new biosynthetic rubber for the production of mass-produced vehicles is an important step towards the realization of Toyota's environmental initiatives, published in October 2015. These initiatives, collectively referred Toyota Environmental Challenge 2050 is a comprehensive plan for a global solution to environmental problems by 2050.

Destiny strokes on the canvas ...

In Japan, electric filling stations became more than a petrol filling station