814

Robots factory Tesla Motors

Although the pace of vehicle production at the factory Tesla has always been very intense, but now стало obvious , it's time to build momentum. Last year, the company produced more than 22,000 electric cars; but the goal for this year - about 35,000 By 2016 the factory will increase the productivity of almost 50%.

Given the fact that very soon will come Model X, Dual Motor Model S is in the process of production, and global demand for smart cars all increases in the past year the company decided to temporarily suspend production, which increase the efficiency pozvolitlo Tesla factory in Fremont, California.

During a pause in the work itself was able to improve assembly line, to increase the efficiency of the assembly shop and the line of machining, as well as improve the working conditions of our employees. Because of design and engineering work, as well as the ongoing modernization, the factory can produce a lot more electric vehicles, while the automation of manufacturing processes and providing more comfortable working environment can increase the speed of production itself.

// player.vimeo.com/video/106564929 video>

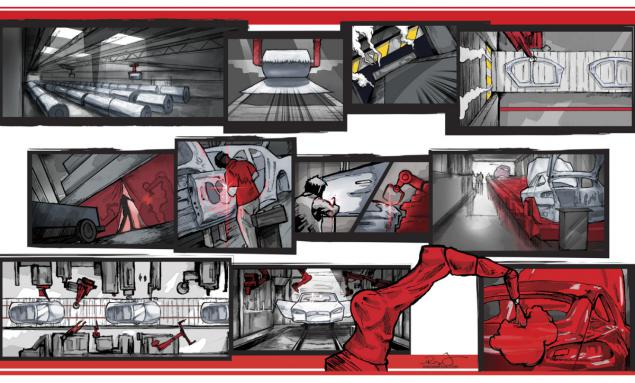

The most significant changes have affected the assembly line of electric vehicles, which previously used steel structures have been replaced by high-tech robots that can easily pick up and move a very precise electric car, while taking up much less space. Very soon, our new factory robots will even be able to perform the installation of batteries on electric vehicles, thus freeing employees from the most physically challenging work throughout the assembly process. In addition, использование robots can reduce the duration of the battery is installed, from four to two minutes.

Robots factory Tesla - is not just a car with a set of specifications, so the staff decided to give them names in honor of the heroes of the film "X-Men". So Xavier stands next to an inclined conveyor line and takes electric cars derailed on the floor. Then, the ice-man, Wolverine and Beast to lift heavier construction, send the car down the pipeline. The storm and the Colossus are at the end of the road, taking cars, then Vulcan and Havok they raised and put back on the rails. For these robots working staff are the real heroes, so the names they have to be appropriate.

In addition to the introduction of robots at the plant to develop more effective laying of flooring. In addition, electric cars are now moving along the assembly line, making the production process simpler and more systematic. On average, the production line is now coming about 1,000 cars a week. At the same time we are confident that their number will increase significantly after a small modernization.

There was also built a new section, which is involved in the production of Dual Motor Model S . High-performance drive unit, previously used in electric cars such models as the 85D and P85D, now produced on highly automated assembly line, the construction of which provides for an increase in production in the future, so that the increase in its efficiency practically does not interfere with the working process.

// player.vimeo.com/video/109168998 video>

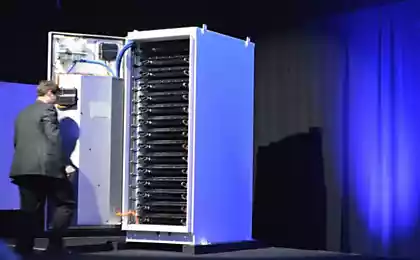

With regard to the battery department, thanks to the new high-tech robots and conveyors now can produce about one million battery cells per day, although earlier the rate was about 800 000 units. The process of creating the base frame of cars is also optimized by a new welding equipment. In addition, it was possible to increase the production rate of 5-10%. Unloading dock was moved closer to the main building of the factory, which made it possible to increase the speed of delivery of cars by sea.

The conversion plant also proved an excellent opportunity to experiment a bit with its design. company Tesla developing so rapidly that simply can not afford to have working environment brings boredom in their employees.

Lighting factory was incomparably better with the idea of replacing the fluorescent light in the LED energy saving lamp. Walls and floor space, which used to be gray, painted white, adding a few bright accents. A comic book artist in a series of illustrations depicted the process of production machines directly on the walls of the factory. The plant has a separate wall, which housed an exhibition of photographs that tell a 54-year history of the company Tesla.

The virtual wall with pictures is a kind of tribute to the emerging motor vehicle, as well as a reminder of the last factory. Before the advent of Tesla's here 26 years ago in this space based company General Motors and Toyota's New United Motor Manufacturing Inc (NUMMI), which produces about 500,000 vehicles a year. In fact, General Motors and the company built a factory two decades earlier. This is what underlies the company in Fremont.

Facts and figures on the two-week re-equipment factory Tesla h3>

- 65 000 man-hours;

- 342 contractor;

- added more than 1, 5 km of the working line conveyor;

- set the 10 largest robots in the world;

- Used 72km Ethernet-cable;

- 45 425 liters of paint;

- dismantled and recycled 50 tons of materials;

- flooded 18,600 square meters of floor epoxy.

Source: geektimes.ru/company/robohunter/blog/263798/