1460

What should we build a spacesuit? Interview with the man who makes the space is not so far away

Nikolai Moiseyev at work (photo source - site FFD) i>

Now the topic of space travel is extremely urgent. Personal space is said on TV, on the Web and write offlan magazines. Many scientists believe that without going beyond the limits of the atmosphere, with the aim of founding settlements beyond Earth, humanity is doomed to extinction. Maybe so, but the base of the colony on the moon, Mars or elsewhere in the solar system is still far.

However, preparatory work is underway, and among those who work for the benefit of space exploration - a small company Final Frontier Design (FFD) based in Brooklyn, New York. The main direction of the company - the creation of space suits and individual elements to them (eg, gloves). This company is now working only four people, however, a team better than some of the public and businesses involved in the same. Leading designer and chief engineer FFD - Nikolai Moiseyev, high engineer who honed his craft for over 20 years.

You have previously worked in the NPP "Star", for more than twenty years. Tell me, please, what was your job there? Can it be said that domestic suits are better than 20 years ago? If so, what progress? B>

Yes, I worked on the Star from 1986 to 2006 and came to the pre-diploma practice in 1985. My last post - the leading designer-looking suits. My responsibilities included the development of new suits and new nodes suits - hinges, gloves, bearings, guidance documentation, the process of working out and testing, production of test reports, translations of modern level skafandrostroeniya in the US (as in other countries in this matter is not very ).

Progress in the development of space suits for heavy nineties and zero years, in my opinion, has been significant. The suit for spacewalk "Orlan" has been modified several times, "Orlan-M" for the Mir space station, "Orlan-M" for the ISS, "Orlan-MK". The last modification made to the computer, and with improvements in general the suit on reliability. Over the years it was significantly increased resource spacesuits, improve mobility in a suit at a pressure and increased the number of possible spacewalks.

That is, the suit has become more reliable and more comfortable. For example, gloves kept only a few thousand cycles on flexion-extension in the wrist joint at an operating pressure of 0, 4 kg / cm 2 sup> and then lost leak, which could result in the release of oxygen at the time of release, with the following significant wear gloves on the main elements.

We end 2005 acknowledgment resource 120 thousand cycles without any deterioration in detail shell carpal joint. And these improvements have been made very much around the suit.

Here I must say that the gloves - the most loaded node in the shell suit, because the astronaut "walks" hands over the railing in weightlessness and does a lot of work gloves, connections - rasstykovok, work with different tools redocking carbines. Me was developed ten modifications of gloves for 20 years at the stars. Every time I went through this painful circle - creation of a prototype, numerous tests, the release of the heap of documentation and certification of gloves for work in open space.

In recent times I said to myself: "That I once again would undertake such a headache? Never! ". But time passed, and again I threw in this fight, because you have new ideas. For example, there was a task to release one size gloves, and ended with the release of "more of the same size" certification brand new glove with the update on the elements by 90 percent. And gloves turned out better than the Americans.

Also, much has been done to develop nodes spacesuits to explore the moon and Mars. It was touched on hinges, providing the mobility of an astronaut in a spacesuit. I was designed and manufactured "underground" means the prototype spacesuit for Mars. What does "underground"? This means that the suit was built without opening theme to it, without an order of the enterprise, only with the tacit consent of the leaders. All development was mine, and now this suit show all correspondents at the stars, but do not say that it was made and tested Nikolay Moiseev on its own initiative without orders from above. The costs of the suit were written off for various purposes. Of course, I helped my friends and helpers.

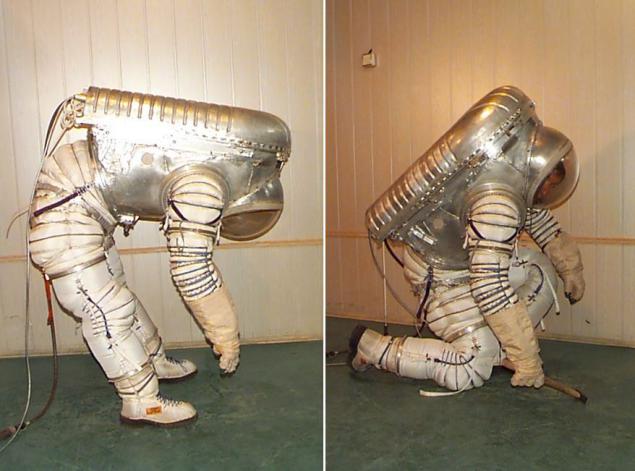

Special thanks to the test department. All development for Mars spacesuit testing and I've been doing over the main work. This space suit can run, jump, push-ups if you want to walk on the slopes in any direction (up, down, sideways to the slope) and get up from the ground to the supine position or lying on his chest. All of this can not be done in any other space suit so far! None of the Russian or American space suits. It is a unique space suit. He has no name. I called him "the prototype spacesuit for Mars." In correspondence with NASA, he was like a Z-Suit (Zvezda-suit, similar to NASA's possessed by the time D-Suit by David Clark, I-Suit by ILC Dover). I built it a few years to 2005.

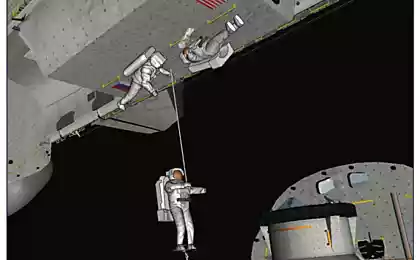

Photo prototype space suit for Mars. From the archive of Nikolai Moiseyev i>

A few words about the features of a space suit at all, to make it clear to our readers who are not familiar with this specific character. One of my former classmate asked me once: "Nicholas, and why did you develop new suits, because there is already old?" I told him that the suit is primarily as a vehicle, because the leading automotive companies of the world every year, or even several times a year are new cars. The new car still has four wheels and a steering wheel (although there are different options), but becomes more reliable, more economical and powerful. And the progress does not stop here. All times are improving.

The suit looks like clothes for a cosmonaut, and it is, but not only. Of course, it is, first - protective equipment and the requirements for it correctly choose the size or the right fit, comfort, thermal comfort, protection against lethal factors of space, etc. And secondly, it is the shell under pressure as the suit provides a person with oxygen for breathing. And because the vacuum outside of a spacesuit, the spacesuit inflated, and it is pressurized. The suit is designed partly as a container for compressed gas. A pressure receptacles are presented engineering requirements - strength at different pressure levels, including three-time margin with the margin of safety, lack of sprouting pressurized mobility under pressure, etc. And this is the specificity of the suit. And materials for space suits must be specially selected durable, certified, with all specifications and a clear source of origin

Now you are a company Final Frontier Design, you - the chief engineer and designer. How did you start working here? How it all began? B>

It all started with the competition NASA "Astronaut Glove." We have got a prize at the end of 2009 for our glove and in early 2010 decided to establish a company (small business). We began to make gloves and suits for space missions. We undertake for other jobs that bring money - it's development and production of technically sophisticated prototyping technology and equipment from different areas.

Demonstration range fitting suits, developed by the company (source - site FFD) i>

What are you currently have major problems in the company? B>

I am a leading designer and chief engineer in our company. For me, the development and design of our products. Many of the decisions we take together.

What problems do you consider most important? B>

The most important task for us is to carry out work on the Space Act Agreement is concluded with us by NASA. The essence of this agreement is that NASA gives us help in certification of our suit for orbital spaceflight. The work will last until the end of 2016 and contains many steps. We also have contracts for the manufacture of suits and gloves for different customers.

C What are the main difficulties you faced FFD? B>

The main difficulty - is money. When I went to the stars, I received a salary, and here we are earning, and if there is a break in the contracts, it becomes a little money. The fact that we are a young and growing company, and we invest the earned money, the money for the development and procurement of materials and equipment.

There is no doubt that you have a very busy schedule. Tell me, please, how many hours a day do you work? B>

We work usually for 9-10 hours a day, 6 days a week, we take work home. There were currently working without weekends and nights, some nights spent at work to do in terms of the suits.

Does the FFD space suits in space on the ISS? Please tell us more about this. B>

No, not yet, but we're working on it. Pilots and astronauts in our space suits flew on several types of aircraft, including jets and perform aerobatics. Processed piloting in the suit as without pressure or under pressure. Tests in high vacuum chambers and a lot of different other tests.

Who are your main customers (unless it is a commercial secret)? Have you representatives SpaceX, Virgin Galactic? B>

We have several customers. Some do not want to disclose their projects is because preparing for patent protection of parts of his work.

SpaceX approached us with a request for proposals, but in the end decided to make their own suits. The informal dialogue at various conferences, we learned that they collect information about the technologies and never with anyone not sign contracts and do not buy anything on the side, and do everything at home, but try to extract the maximum information on the key points. In my opinion, it is ugly.

Virgin Galactic has not yet (?) Intention to use spacesuits. And this is a mistake, because the flights will take place on the "cosmic" altitudes and just an oxygen mask will not save when cabin depressurization.

Do you have your company's competitors? Who are they? B>

Yes, there are competitors. First of all, the two US companies are engaged in more than 50 years, spacesuits. It ILC Dover and David Clark. Their products are very heavy and expensive. In my opinion some new solutions have long gone. Orbital Outfitters from Hollywood, California, is a relatively new company. Yes, they made the costumes for the film, and decided that they could make real suits, and not only for shooting. Their suit anywhere and never flew and was only shown to the public. There are a few photos pressurized spacesuit, which show that they have a problem with the sprouting suit under pressure. Neck ring located at nose test after pressure build-up in the suit, but because until then no pressure in the suit, it was located on the chest!

Now, the company took a break from the move to Texas. They have an agreement with XCOR. When flights are their spacecraft - is unknown. Maybe next year.

It turns out that we are competing with a star, where I worked for many years, although it is not clear competition. Some of the "jumpers from a great height" and appealed to us and to them. But their projects do not come to the realization, like Felix (referring to Felix Baumgartner ).

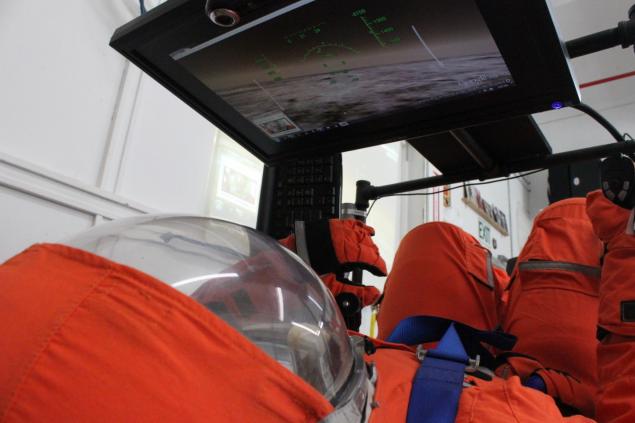

Photo FFD space suit in the simulator simulate landing on the moon, Mars and Earth. From the site FFD. I>

You are working on a spacesuit for Mars. Tell me, please, when it is planned completely ready spacesuit? What are the differences between the spacesuit for spacewalks and spacesuit to stay on the surface of Mars? B>

Indeed I am not working on a spacesuit for Mars. There is no doubt that the new elements with advanced technologies that we create can be used in future Martian spacesuit. No specific time frame, because we need funding. But, for example, we have a grant from NASA to develop a new EVA gloves. New lightweight glove with new unique characteristics of mobility and protection in fact can be used on Mars! And technology, tested the gloves can be applied to other nodes suit.

Differences suit to work on the surface of the Moon / Mars spacesuit to work in conditions of weightlessness much. Weight spacesuit for Mars must be smaller than about 2 times the weight of the existing EVA spacesuits (120-130 kg). After all, the existing EVA spacesuits designed for weightlessness. Reducing weight twice this challenge and to declare that we can use eagle for the Moon and Mars with minimal alterations, unprofessional.

Sublimator located on the back of a backpack life support system will not work in the Martian atmosphere, as it needs a high vacuum.

Controls LSS must be electronically controlled and not with hydropneumatic, etc. etc. These electronic components must be of class "space", and with them the problem in Russia.

In the lunar or Martian suits should be waist joint for inclinations to control soil samples. He just needs to gravitational conditions. And it is not now Orlan EVA suit. The lap joint is not so necessary in weightlessness as on the planet. To implement the lap joint at Orlan, to do short breastplate. It is several years on such traditional businesses as a star. This new short body suit for the Moon and Mars will have no place for the old hydro-pneumatic controls LSS what is now crammed with breast shell eagle. And it's a lot of work. Failure to understand these obvious things says mindedness supervisors, alleging ready to Orlan lunar expeditions after minor modifications.

There are a few specific points that I will not disclose, and that I know how to use my suggestions and inputs.

What are your plans in the framework of work in the FFD, for the near future? B>

There is a lot of interesting work and operations in the new suits.

UPD. B> Geektimes congratulates FFD: now signed a contract agency NASA . FFD will now work on the gloves high pressure EVA, followed by passing the test in the Johnson Space Center, NASA.

Dear readers! If you have any questions - ask in the comments, I will give a list of questions to Nicholas, he has kindly agreed to answer them. We get answers firsthand.

Source: geektimes.ru/post/250284/

The cycle path from solar panels length of 70 meters for six months can provide electricity for the house for the whole year

Lily: smart camera drone flying over you