816

Scientists have found a way to reduce the cost of production of magnets

Researchers from the Department of Energy of Ames Laboratory in Iowa обнаружили relatively inexpensive way to increase the performance of the permanent magnets at high temperatures. Instead of expensive rare earth element dysprosium they propose to use cerium, and cobalt.

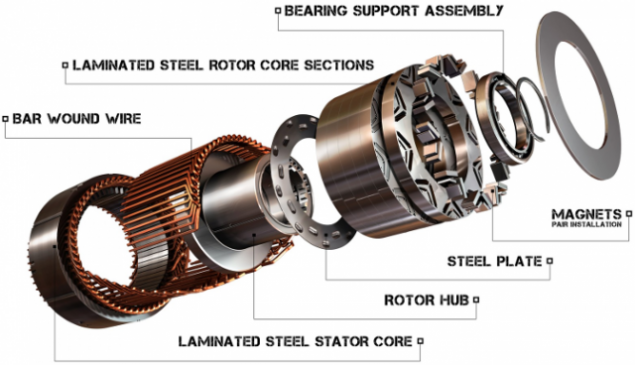

New technologies are often highly dependent on scarce resources. For example, permanent magnets, which are used in electric motors (and the theme of electric vehicles is very popular), usually consist of an alloy of неодима, boron and iron . Such magnets - the strongest available and they retain their properties over the years (the loss of magnetization in 10 years does not exceed 2%).

For operation at elevated temperatures (for the same engine) required magnets with high точкой Kurnakova - temperature, after which their magnetic properties disappear. Neodymium - itself already a rare earth element, and to increase operating temperatures magnets required to add relatively large proportions dysprosium. This is a rare and expensive rare earth element (more than € 10,000 per kg).

The researchers were able to replace the combination of cerium, dysprosium and cobalt. This trick reduces the cost of the resulting magnet 20-40%. At the same time the alloy, better than any other operating at temperatures above 150 ° C. These magnets can be used in heavy duty engines. With the coming of endemic elektromobilizatsiey even looming on the horizon elektrosamolёtami the possibility of making such magnets is difficult to overestimate.

Source: geektimes.ru/post/250026/

Meeting and parting with Mercury

Google will spend $ 150 million to the racial composition of the company's employees has become more diverse