3211

Chopping boards

43 photos and some text

In each apartment there is a kitchen tool needed for cutting various products - cutting board. Originally it was a stone, then iron, bronze, and then later became wooden.

Although only recently emerged plastic counterparts, wooden board still as popular. I recently managed to get into the studio, where they make cutting boards, but what I saw did not come with my ideas about such a simple utilitarian kitchen items, which cut the vegetables, meat and other food.

As the theater begins with a hanger, and a workshop where they make wooden products begins from the warehouse, where the wood is. To our master, the work of which will be discussed today, it comes as a finished product, dried at a certain temperature for several years. Fresh wood used to manufacture the boards can not, because the finished product will deform with time from shrinkage.

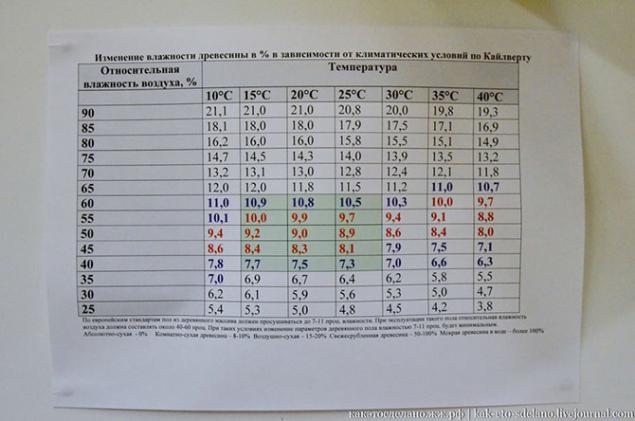

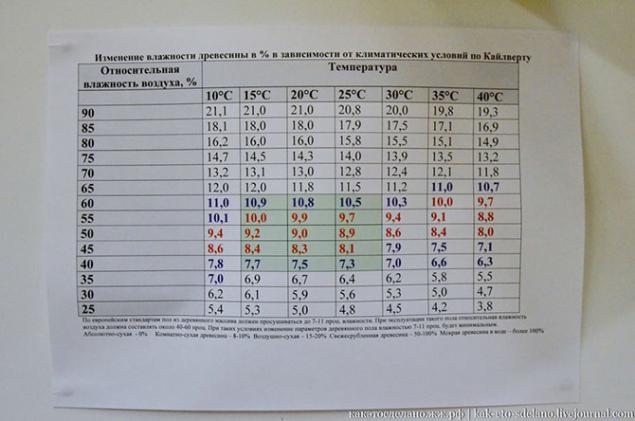

Here in the warehouse to maintain a certain temperature and humidity, which do not give the wood is too dry up and become too wet. On this table, which hangs on the wall of the workshop can be seen optimum moisture percentage at different temperatures.

Here hangs hygrometer showing the degree of humidity in the room. True Master said that he had the wrong readings).

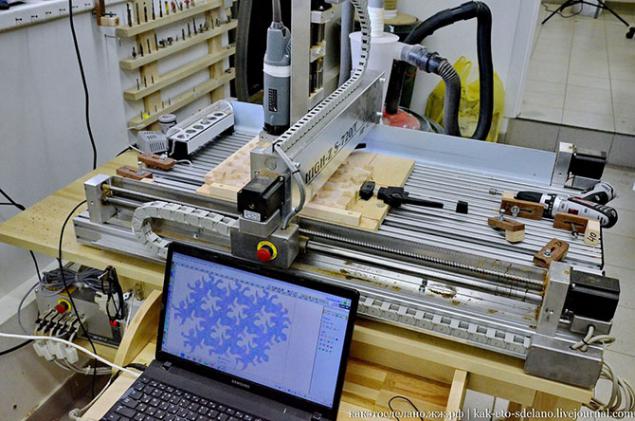

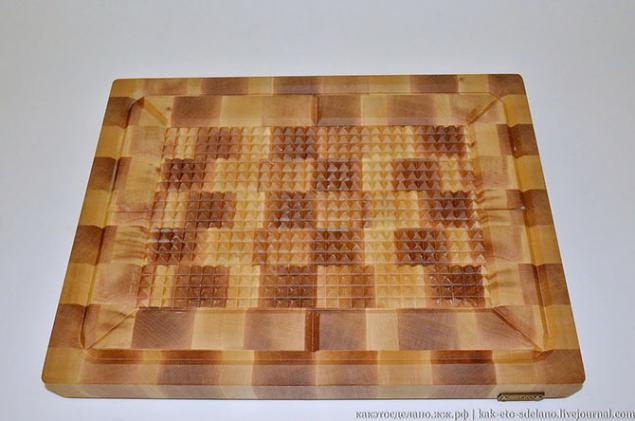

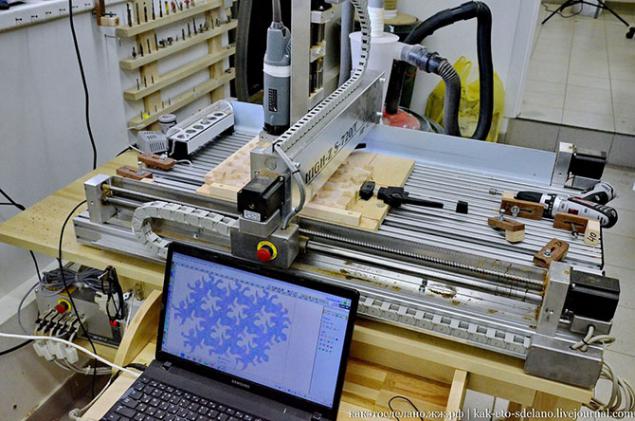

For making some boards with a particularly complex pattern used CNC (computer numerical control). The machine is small enough to connect it to a laptop with a predetermined program.

Drawing boards, over which now operates the cutter inspired famous work of Maurits Escher's "Reptiles".

If desired, the cutter will do wonders

Here is the board after the operation of the machine. If you look carefully, you'll see that this future board glued together from pieces. Why did we find so forth.

If the base of the board is made of walnut, the insert was excised from other types of wood, different texture and color - oak and rosewood.

As I said the master, the machine cut out pieces on the board in such a way that inserting other figures of reptiles show no gaps. Figures are adjusted to each other very tightly.

In this photo you can see examples of bonding. Multicolored piece is glued from various wood species. Because such material will be glued one of the most complex in the manufacture of boards. At the end of the post you can see it.

The wizard takes just a message board, processes it, aligns edges. Then the board is cut into pieces that turn a face part and glued together. And bonding is not done in any order, and in a special way to the annual rings are oriented in opposite directions, it will prevent the board from deformation with changes in humidity.

Why do this? Due to the vertical arrangement of the wood fibers is not longer knives tupyatsya as the knife blade does not cut the fiber, as in conventional boards and penetrates between - slides. Fibers are reset after culinary hassle her. Accordingly, the board does not deteriorate, and the chef does not have to sharpen knives several times per shift, as is the case with conventional boards.

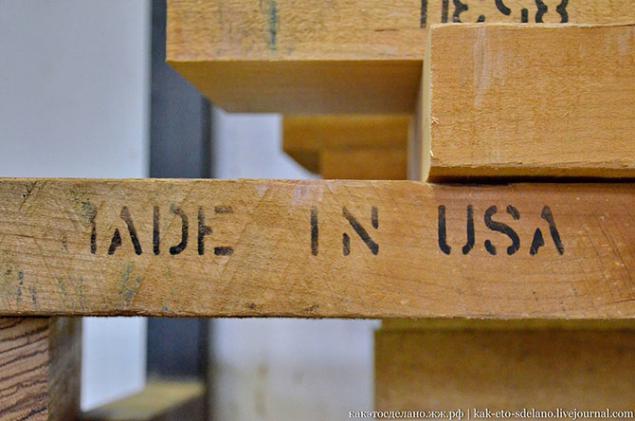

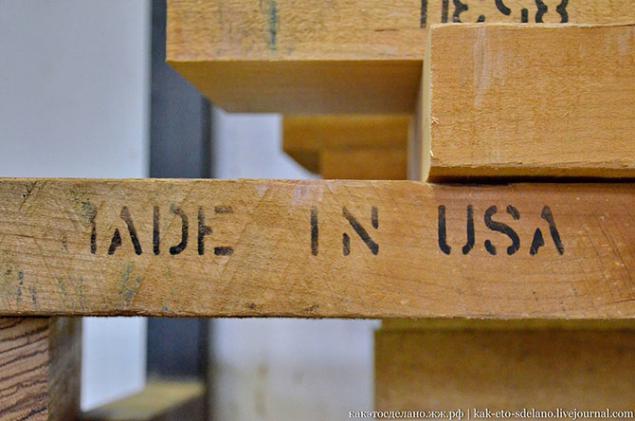

As a material other than walnut, hornbeam, ash, maple, oak and beech are also used precious woods such as American cherry, movingu mahogany. As you can see by the markings on the timber it from the US, there are from South America and Africa.

The other types of wood.

14

After the wood is cut into pieces and turn the end of the top, it is glued and clamped in the clamp - a special press. As you can see here panels of different thicknesses. The one that will become thicker board, and thinner boards will be used for cutting patterns and shapes on the surface of the boards of the future, like the figures from "Reptiles". Shield after gluing will be ready in an hour, but subjected to a load in 24 hours is recommended.

For bonding uses a special adhesive not having in its composition formaldehyde permitted for food contact, and having a greater water resistance.

Here is the room where all the necessary tools for joinery Affairs.

Clean and tidy perfect! As you can see, in the workshop have all tools and machines for the manufacture of any wooden products. This paradise carpenter

Special clamps for large boards.

The board with reptiles we will not touch it, work on it will be carried out more than one hour because otherwise worked. Once it is glued, it is run through the machine for grinding - surface gauge. In essence it is a modern plane.

Then a circular saw cut off the sidewall of the board.

Boca grinded on another machine with vertical movement of the tape. Immediately rounded corners.

Then again, the board is run through a drum sander.

At this time the surface is polished more delicately. But that's not all.

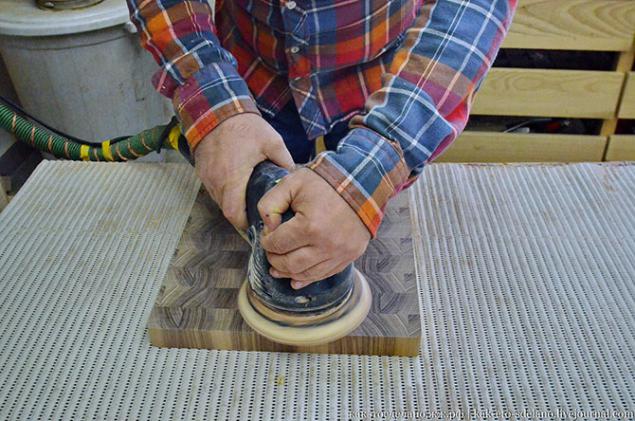

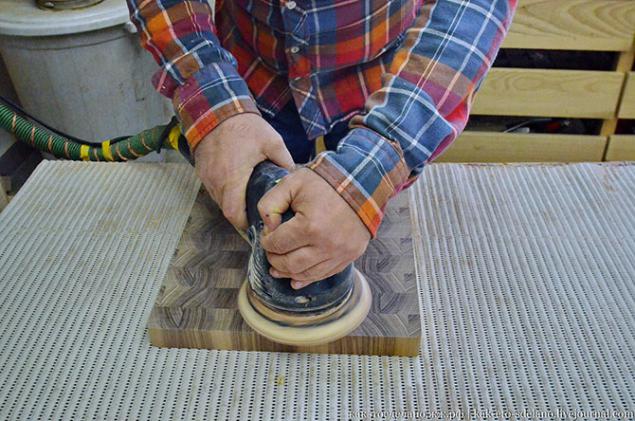

For each machine fastened pumps that collect sawdust from wood processing. After processing machines polished product manual grinder. First, use a coarse grit sandpaper 120 units, followed by 240 units to the final polish board

Finishing touches to round the edges and can say that carpentry work over the board over.

After all the above operations, the board takes a bath of mineral oil, which has no taste, no color, no smell. The oil is produced from oil, but it is perfectly safe, and it even used in the cosmetic field.

The same board with the reptiles, which is shown at the beginning of Lent in the same turn. After a while, when the board is oiled, it will dry off, then again processed, hot mixture of mineral oil and wax in a ratio of 4/1.

In the same oil bath and leave other boards.

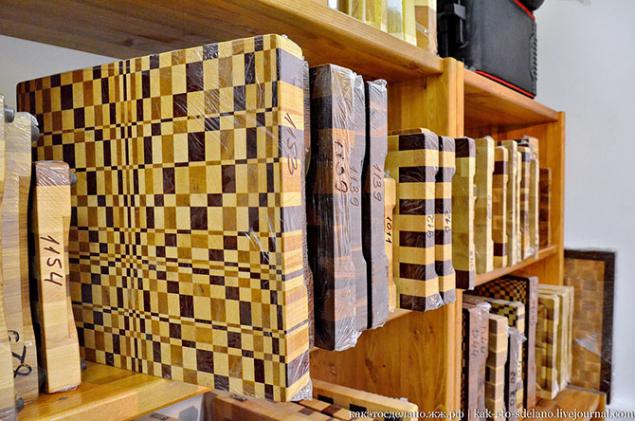

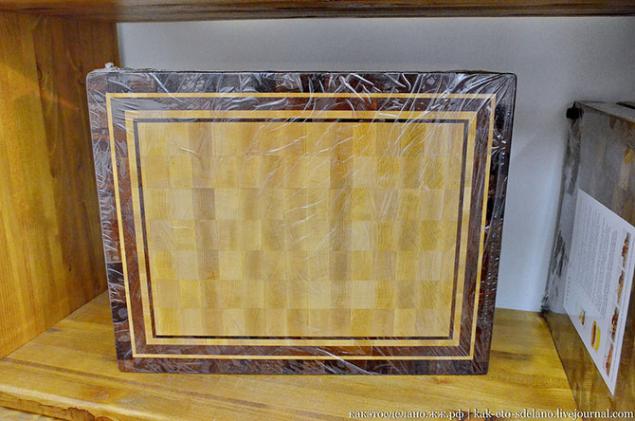

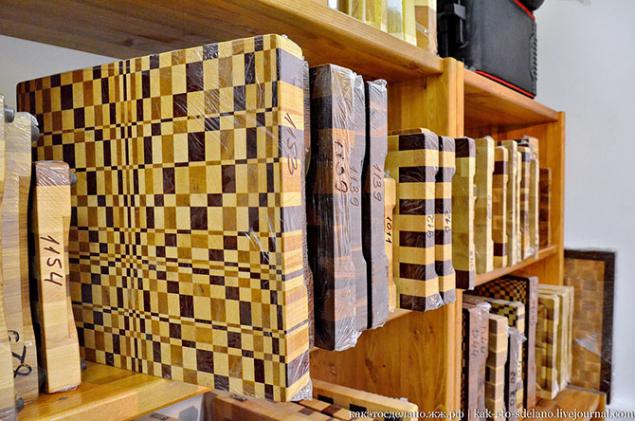

Now go to "Show room" elite cutting boards). In this room, the boards are packed and looking forward to seeing his future master

Hygrometer to monitor the level of humidity.

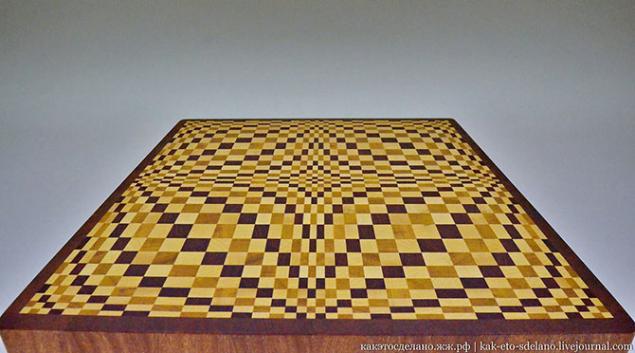

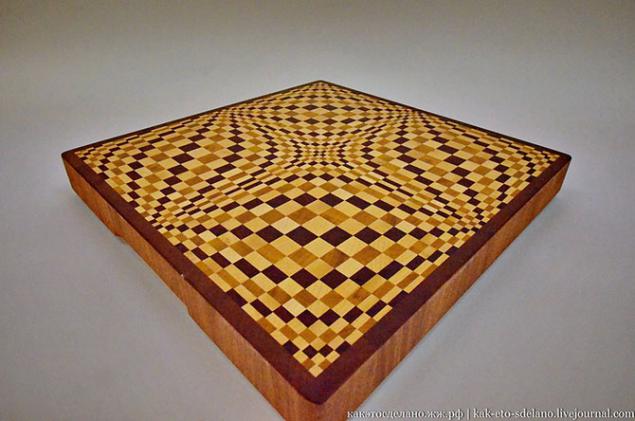

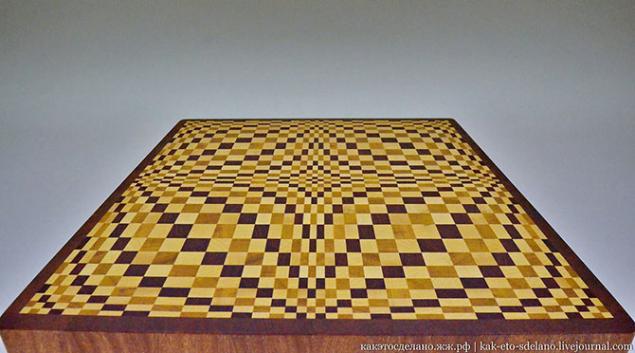

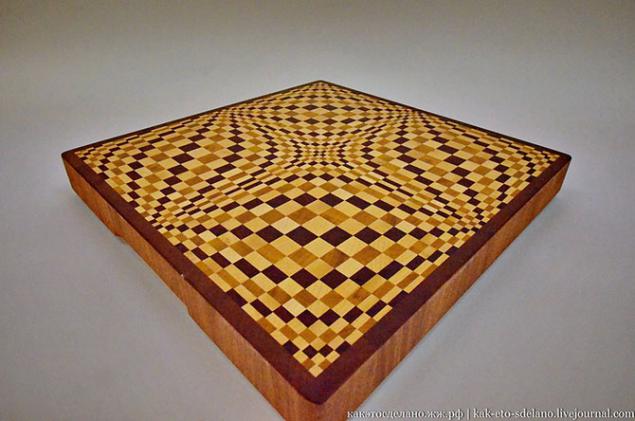

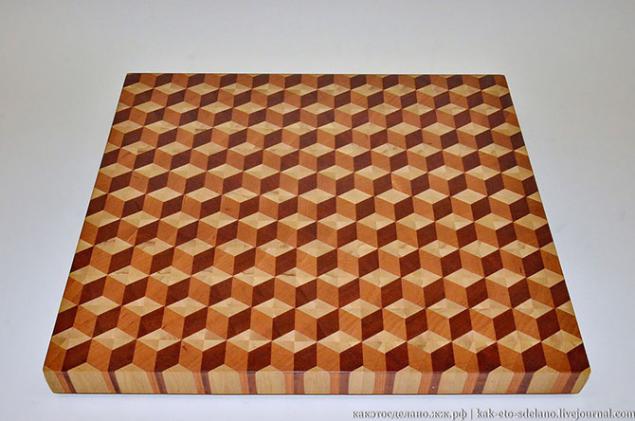

This board just broke my pattern of simple utilitarian kitchen utensils! I can not imagine how you can dare to shred products a work of art

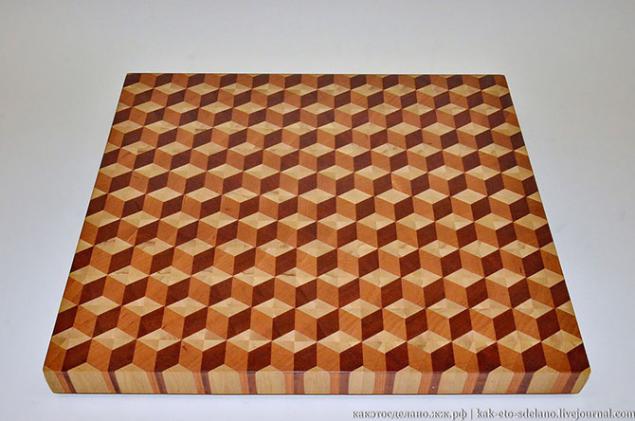

Spent a lot of hours to make a board with a 3D effect. By the way, these boards are the most expensive, and it is clear why.

33

34

35

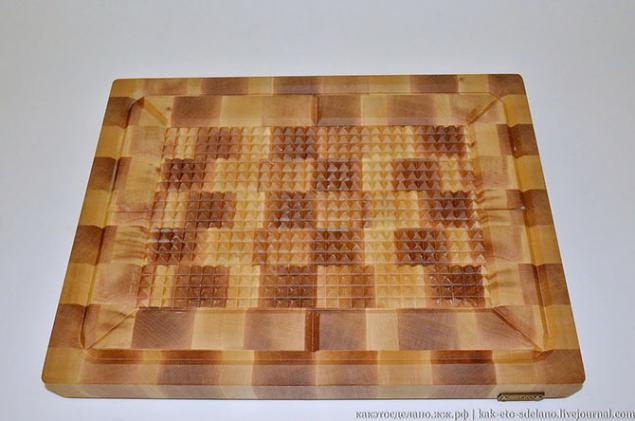

And this board can safely hang a picture instead!

The wizard also manufactures special boards for beating the meat. There even has channels to drain the blood.

I will add that the end of the board due to the material characteristics and the production obtained thick and heavy, but do not roll on the table / work surface cooking. No need to lay a cloth or damp cloth / towel, stick with risk. The boards are equipped with additional rubber (sometimes silicone or plastic) feet that are insured by soaking accidentally fell under the water board.

39

40

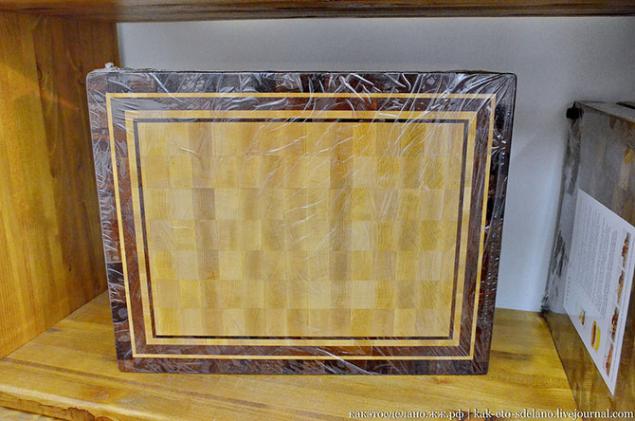

After the board has passed all stages of the production process, it is packaged in the film.

A bit of hot air and you're done.

Latest:

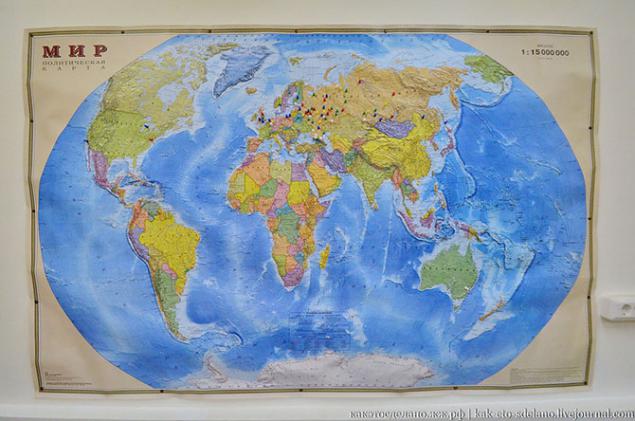

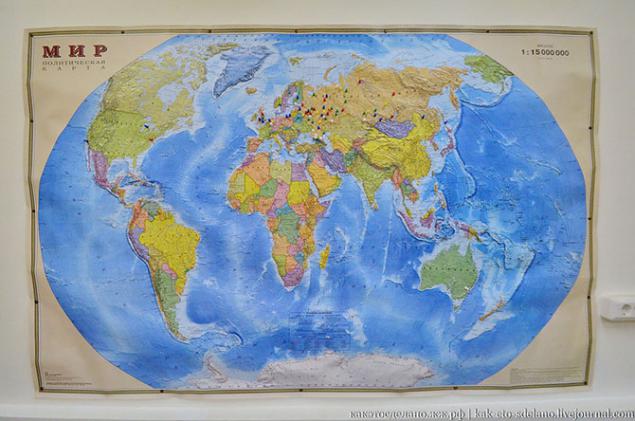

This map shows where it goes ordered boards - mainly Russia, Europe, the US, there is even Japan and Australia.

Hence

In each apartment there is a kitchen tool needed for cutting various products - cutting board. Originally it was a stone, then iron, bronze, and then later became wooden.

Although only recently emerged plastic counterparts, wooden board still as popular. I recently managed to get into the studio, where they make cutting boards, but what I saw did not come with my ideas about such a simple utilitarian kitchen items, which cut the vegetables, meat and other food.

As the theater begins with a hanger, and a workshop where they make wooden products begins from the warehouse, where the wood is. To our master, the work of which will be discussed today, it comes as a finished product, dried at a certain temperature for several years. Fresh wood used to manufacture the boards can not, because the finished product will deform with time from shrinkage.

Here in the warehouse to maintain a certain temperature and humidity, which do not give the wood is too dry up and become too wet. On this table, which hangs on the wall of the workshop can be seen optimum moisture percentage at different temperatures.

Here hangs hygrometer showing the degree of humidity in the room. True Master said that he had the wrong readings).

For making some boards with a particularly complex pattern used CNC (computer numerical control). The machine is small enough to connect it to a laptop with a predetermined program.

Drawing boards, over which now operates the cutter inspired famous work of Maurits Escher's "Reptiles".

If desired, the cutter will do wonders

Here is the board after the operation of the machine. If you look carefully, you'll see that this future board glued together from pieces. Why did we find so forth.

If the base of the board is made of walnut, the insert was excised from other types of wood, different texture and color - oak and rosewood.

As I said the master, the machine cut out pieces on the board in such a way that inserting other figures of reptiles show no gaps. Figures are adjusted to each other very tightly.

In this photo you can see examples of bonding. Multicolored piece is glued from various wood species. Because such material will be glued one of the most complex in the manufacture of boards. At the end of the post you can see it.

The wizard takes just a message board, processes it, aligns edges. Then the board is cut into pieces that turn a face part and glued together. And bonding is not done in any order, and in a special way to the annual rings are oriented in opposite directions, it will prevent the board from deformation with changes in humidity.

Why do this? Due to the vertical arrangement of the wood fibers is not longer knives tupyatsya as the knife blade does not cut the fiber, as in conventional boards and penetrates between - slides. Fibers are reset after culinary hassle her. Accordingly, the board does not deteriorate, and the chef does not have to sharpen knives several times per shift, as is the case with conventional boards.

As a material other than walnut, hornbeam, ash, maple, oak and beech are also used precious woods such as American cherry, movingu mahogany. As you can see by the markings on the timber it from the US, there are from South America and Africa.

The other types of wood.

14

After the wood is cut into pieces and turn the end of the top, it is glued and clamped in the clamp - a special press. As you can see here panels of different thicknesses. The one that will become thicker board, and thinner boards will be used for cutting patterns and shapes on the surface of the boards of the future, like the figures from "Reptiles". Shield after gluing will be ready in an hour, but subjected to a load in 24 hours is recommended.

For bonding uses a special adhesive not having in its composition formaldehyde permitted for food contact, and having a greater water resistance.

Here is the room where all the necessary tools for joinery Affairs.

Clean and tidy perfect! As you can see, in the workshop have all tools and machines for the manufacture of any wooden products. This paradise carpenter

Special clamps for large boards.

The board with reptiles we will not touch it, work on it will be carried out more than one hour because otherwise worked. Once it is glued, it is run through the machine for grinding - surface gauge. In essence it is a modern plane.

Then a circular saw cut off the sidewall of the board.

Boca grinded on another machine with vertical movement of the tape. Immediately rounded corners.

Then again, the board is run through a drum sander.

At this time the surface is polished more delicately. But that's not all.

For each machine fastened pumps that collect sawdust from wood processing. After processing machines polished product manual grinder. First, use a coarse grit sandpaper 120 units, followed by 240 units to the final polish board

Finishing touches to round the edges and can say that carpentry work over the board over.

After all the above operations, the board takes a bath of mineral oil, which has no taste, no color, no smell. The oil is produced from oil, but it is perfectly safe, and it even used in the cosmetic field.

The same board with the reptiles, which is shown at the beginning of Lent in the same turn. After a while, when the board is oiled, it will dry off, then again processed, hot mixture of mineral oil and wax in a ratio of 4/1.

In the same oil bath and leave other boards.

Now go to "Show room" elite cutting boards). In this room, the boards are packed and looking forward to seeing his future master

Hygrometer to monitor the level of humidity.

This board just broke my pattern of simple utilitarian kitchen utensils! I can not imagine how you can dare to shred products a work of art

Spent a lot of hours to make a board with a 3D effect. By the way, these boards are the most expensive, and it is clear why.

33

34

35

And this board can safely hang a picture instead!

The wizard also manufactures special boards for beating the meat. There even has channels to drain the blood.

I will add that the end of the board due to the material characteristics and the production obtained thick and heavy, but do not roll on the table / work surface cooking. No need to lay a cloth or damp cloth / towel, stick with risk. The boards are equipped with additional rubber (sometimes silicone or plastic) feet that are insured by soaking accidentally fell under the water board.

39

40

After the board has passed all stages of the production process, it is packaged in the film.

A bit of hot air and you're done.

Latest:

This map shows where it goes ordered boards - mainly Russia, Europe, the US, there is even Japan and Australia.

Hence