872

Two-storey house in one season

Every man must make in the lives of four things: plant a tree, raise a son and build a house and put it all online

Today, I will tell you how to half a year, you can build a two-storey house.

So, my dear, Garner chips, patience and ... gone!

Pictures will be more than 200 pieces. All questions to answer after.

© CTPAHnic 2013

Background:

Last year, my wife and I, decided to take a desperate step. It was necessary to improve living conditions, for three children, all heterosexual - in the words of one well-known satirist. And we still want to live in silence, alone, in a separate way to say indoors.

We sell a kopeck piece in a prestigious area and bought a small house in the city.

Kopeck piece 47 squares (26 residential), sold for 3 million rubles.

House found over 2,100. Remains, therefore, allowed the construction site.

Earth is not a lot, but there are all communications, central water, central heating, too, electricity itself from the wires flows well and tank under the sewers have already dug 12 cubes. I do not want to live.

The only thing we did not like, it is still a Soviet repair and living area of 65 squares. It will be small, we decided and start smashing to the ground!

House seemingly simple, some thousands were built in the Soviet Union

3 ...

4 ...

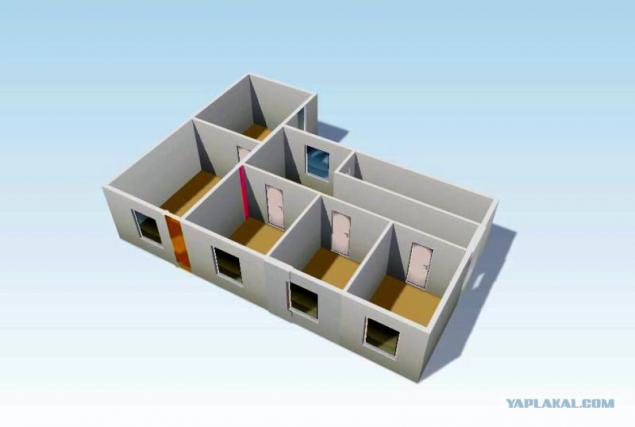

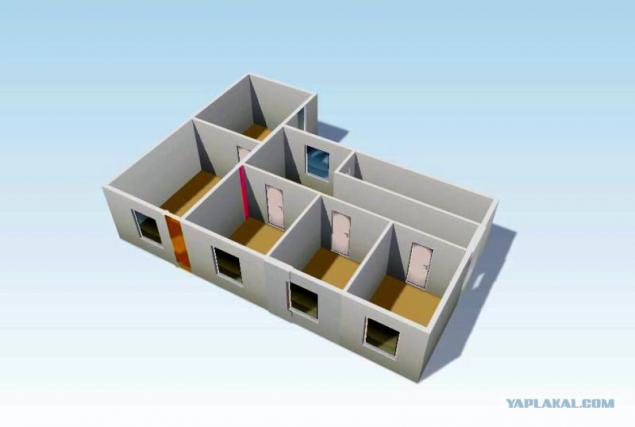

First was the plan

6 ...

7 ... then clearing the territory from buildings

8 ... Sorry I walked away for a minute :)

Inside, too started to break. It was a stove

9 ... The daughter helped

10 ... It was decided to use frame technology as the most inexpensive and fast

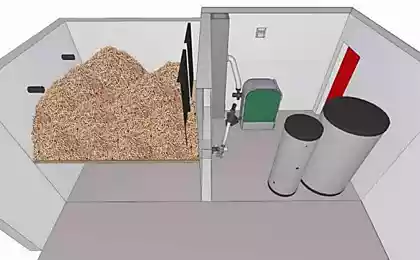

11 ... The walls of the garage and the house are uneven, had to make their margins and cover slag, sawdust

12 ... voids averaging about 10 centimeters

13 ... One wall is ready. 1 work day is over

14 ... Put the struts and a second wall

15 ... So far everything looks pretty shaky and the wind shakes

... 16 top too, we catch a couple of boards

17 ... This is a new entrance. Login now be from the yard. However, an old entry is not cleaned, it will lead in the technical room

18 ... View from inside. Fasten the frame to the house on the reinforced corners. All voids subsequently filled with pieces of mineral wool

19 ... you will cut the entrance to the old house

20 ... between home and frame voids up to 30 centimeters. They also filled shlakoopilom and pieces of mineral wool that mice would not ran :)

21 ... starting to make overlap in the bath. Oh yeah, I forgot to say. From the garage, I'm doing a sauna and a relaxation room of 50 square meters :)

22 ... I myself do not pull hire experienced Tajiks. Works only on the roofs of 10 years.

23. Roads, but I was able to negotiate for 500 rubles square meter. The overlap does not have the money. Or rather, I did not give them :)

24. For nakosyachili they overlap and stropilkoy. I had some things to alter and enhance

25 ... Make quickly. They work from 8 am to 22 pm

26 ... Covering made from 150h50 board. I do not follow. It was necessary to make them paired the board, for the span 4.5 meters. Although no load on them in practice, but a margin of safety should be always.

27. It can not be done! Then sewed the side boards and extra unloaded rafters making banners on the walls

28 Some details about the frame. It is not a traditional Canadian and Finnish and American. It is rather a mixture of all technologies. Shoals of course a lot of legs in substantially all of the technology.

29 street view

30. The Boards took six meters. 150h50 natural moisture. Since building began in May, the boards were still winter, dry. But the amount of walking is very strong, especially in thickness.

In the photo: the scheme washed down bolts for the window.

31 ... crossbars openings of windows and doors are made of the same dual-board. Between them lay a useful gasket. I did not do so then had a gap zapenivat.

32 ... the beginning of the second floor ceiling. Board 200x50 60 (59) centimeters below the insulation

33 Top view. In places openings double board-lining and special shoes for the boards. It is better to do even three boards

34. In the background, continues to break construction. KAMAZ exported 5 boards. Rather presented to people for firewood. Broken bricks used in the dumping.

35 ... The guys are digging day and night :)

36 ... The roof of the old house. Soon it will break. Ah did not go to the rains. Let me remind you - we as a family are living there with all things ...

37. stitched the ceiling of the first floor, it will lay down for the mineral wool insulation and heat at the edges outhouse. For the binder use SML (glass magnesia sheet) Do not burn, does not gets wet, it does not rot, but terribly fragile.

38.Eto outhouse frame overlap between the old house and garage room. The photo lists LSU 10 mm. I wanted to put them on the wall, but they do not hold the screws and break easily, even by hand. Then I moved on to OSB-3 0.9 MM

39. View of the attic bath. Yet eliminated shoals of truss system

40.

41. so do not need to

42. and so, too. The load is the center of the ceiling, and should be on the opposite wall. Generally, the triangle in the opposite direction.

43. Putting outhouse wall of the second floor. It turns out panel height of three meters and a width of about two and a half. You can raise way, if there is no wind.

44. The raised panel with one hand. Consolidated interim the struts.

45. The same is true on the other side. The inner wall of the final set!

46. One day of the second floor is ready!

47. Side view

48. Street

49. Breaking the roof of the old house. 5000 rubles and half-day work of the three Tajiks

50. On the second floor ceiling had pomudrit. The level of additional building and the old house is different.

51. Use old logs, they are so strong that bounces off the ax!

There were three ways to align!

The logs are set on end and fixed braces

52. Here we have used logs and boards 200x50

53. Or simply bolted board 200x50, staples and such a mother!

Below main wall, so the force on the deflection is not necessary. Only smooth surface.

54. The top engineering :)

For clever: Logs 6.5 meter, 30 centimeters in thickness, 2 m, hold 500 kilograms per square meter.

55. Cat already like. After a city apartment he then paradise!

56. investigate the strength :)

57. Slab - a board 200x50 60 (59) cm, with jumpers, 2 meters (1.99) dimensions of a mineral wool.

58. hemmed bottom fiberboard. As you can see probably the first and second floor there is a difference of 50-70 centimeters. This space is ventilated, to couple the output from the first floor. This will be provided for the air holes and the vent grille.

Source:

Today, I will tell you how to half a year, you can build a two-storey house.

So, my dear, Garner chips, patience and ... gone!

Pictures will be more than 200 pieces. All questions to answer after.

© CTPAHnic 2013

Background:

Last year, my wife and I, decided to take a desperate step. It was necessary to improve living conditions, for three children, all heterosexual - in the words of one well-known satirist. And we still want to live in silence, alone, in a separate way to say indoors.

We sell a kopeck piece in a prestigious area and bought a small house in the city.

Kopeck piece 47 squares (26 residential), sold for 3 million rubles.

House found over 2,100. Remains, therefore, allowed the construction site.

Earth is not a lot, but there are all communications, central water, central heating, too, electricity itself from the wires flows well and tank under the sewers have already dug 12 cubes. I do not want to live.

The only thing we did not like, it is still a Soviet repair and living area of 65 squares. It will be small, we decided and start smashing to the ground!

House seemingly simple, some thousands were built in the Soviet Union

3 ...

4 ...

First was the plan

6 ...

7 ... then clearing the territory from buildings

8 ... Sorry I walked away for a minute :)

Inside, too started to break. It was a stove

9 ... The daughter helped

10 ... It was decided to use frame technology as the most inexpensive and fast

11 ... The walls of the garage and the house are uneven, had to make their margins and cover slag, sawdust

12 ... voids averaging about 10 centimeters

13 ... One wall is ready. 1 work day is over

14 ... Put the struts and a second wall

15 ... So far everything looks pretty shaky and the wind shakes

... 16 top too, we catch a couple of boards

17 ... This is a new entrance. Login now be from the yard. However, an old entry is not cleaned, it will lead in the technical room

18 ... View from inside. Fasten the frame to the house on the reinforced corners. All voids subsequently filled with pieces of mineral wool

19 ... you will cut the entrance to the old house

20 ... between home and frame voids up to 30 centimeters. They also filled shlakoopilom and pieces of mineral wool that mice would not ran :)

21 ... starting to make overlap in the bath. Oh yeah, I forgot to say. From the garage, I'm doing a sauna and a relaxation room of 50 square meters :)

22 ... I myself do not pull hire experienced Tajiks. Works only on the roofs of 10 years.

23. Roads, but I was able to negotiate for 500 rubles square meter. The overlap does not have the money. Or rather, I did not give them :)

24. For nakosyachili they overlap and stropilkoy. I had some things to alter and enhance

25 ... Make quickly. They work from 8 am to 22 pm

26 ... Covering made from 150h50 board. I do not follow. It was necessary to make them paired the board, for the span 4.5 meters. Although no load on them in practice, but a margin of safety should be always.

27. It can not be done! Then sewed the side boards and extra unloaded rafters making banners on the walls

28 Some details about the frame. It is not a traditional Canadian and Finnish and American. It is rather a mixture of all technologies. Shoals of course a lot of legs in substantially all of the technology.

29 street view

30. The Boards took six meters. 150h50 natural moisture. Since building began in May, the boards were still winter, dry. But the amount of walking is very strong, especially in thickness.

In the photo: the scheme washed down bolts for the window.

31 ... crossbars openings of windows and doors are made of the same dual-board. Between them lay a useful gasket. I did not do so then had a gap zapenivat.

32 ... the beginning of the second floor ceiling. Board 200x50 60 (59) centimeters below the insulation

33 Top view. In places openings double board-lining and special shoes for the boards. It is better to do even three boards

34. In the background, continues to break construction. KAMAZ exported 5 boards. Rather presented to people for firewood. Broken bricks used in the dumping.

35 ... The guys are digging day and night :)

36 ... The roof of the old house. Soon it will break. Ah did not go to the rains. Let me remind you - we as a family are living there with all things ...

37. stitched the ceiling of the first floor, it will lay down for the mineral wool insulation and heat at the edges outhouse. For the binder use SML (glass magnesia sheet) Do not burn, does not gets wet, it does not rot, but terribly fragile.

38.Eto outhouse frame overlap between the old house and garage room. The photo lists LSU 10 mm. I wanted to put them on the wall, but they do not hold the screws and break easily, even by hand. Then I moved on to OSB-3 0.9 MM

39. View of the attic bath. Yet eliminated shoals of truss system

40.

41. so do not need to

42. and so, too. The load is the center of the ceiling, and should be on the opposite wall. Generally, the triangle in the opposite direction.

43. Putting outhouse wall of the second floor. It turns out panel height of three meters and a width of about two and a half. You can raise way, if there is no wind.

44. The raised panel with one hand. Consolidated interim the struts.

45. The same is true on the other side. The inner wall of the final set!

46. One day of the second floor is ready!

47. Side view

48. Street

49. Breaking the roof of the old house. 5000 rubles and half-day work of the three Tajiks

50. On the second floor ceiling had pomudrit. The level of additional building and the old house is different.

51. Use old logs, they are so strong that bounces off the ax!

There were three ways to align!

The logs are set on end and fixed braces

52. Here we have used logs and boards 200x50

53. Or simply bolted board 200x50, staples and such a mother!

Below main wall, so the force on the deflection is not necessary. Only smooth surface.

54. The top engineering :)

For clever: Logs 6.5 meter, 30 centimeters in thickness, 2 m, hold 500 kilograms per square meter.

55. Cat already like. After a city apartment he then paradise!

56. investigate the strength :)

57. Slab - a board 200x50 60 (59) cm, with jumpers, 2 meters (1.99) dimensions of a mineral wool.

58. hemmed bottom fiberboard. As you can see probably the first and second floor there is a difference of 50-70 centimeters. This space is ventilated, to couple the output from the first floor. This will be provided for the air holes and the vent grille.

Source: