1433

History of another electric bikes with their hands: reloaded

Greetings, dear Habrasoobschestvo.

Inspired by the articles authored by chomper

«History of another electric bikes with their hands»

and «History of another electric bikes with their hands v2.0» , decided to create something of their own.

What happened, so to speak, "based on" and a lot of photos and text - under the cut.

Adherents motor-wheels I have to say - I do not want a weight of 7kg or on the front wheel or rear. I work on the third floor and the stairs to carry this charm - no really, thank you. I>

Sourcebook was taken the concept and rethought to fit your needs.

Motives built partially trivial - I want to go to work by bike, but one slide completely kills all impulses, and partly not - like their hands to feel "elektrobayk».

The basis was taken purebred bike, bought many years ago from peddlers "ad from Europe ».

From purchased: h4> Electric (model outrunner) size 6354 kv200 50,178,508

Now, construction sites h4> From attachment of spokes sprocket wheel to transmit effort was abandoned immediately.

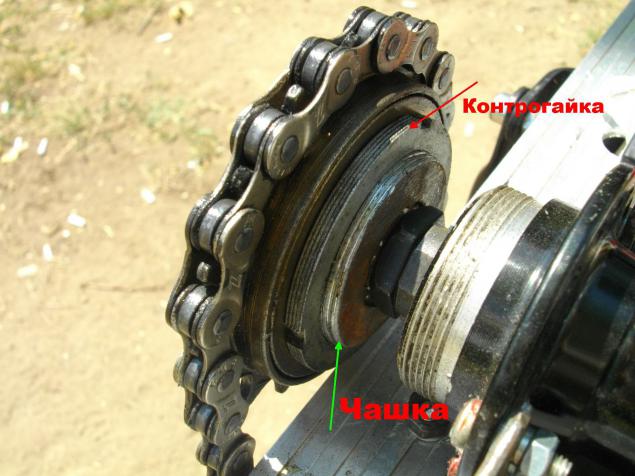

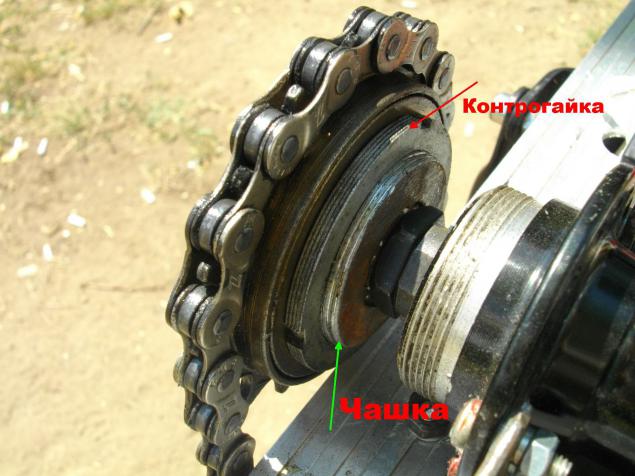

Frivill (ratchet) h4> Mounted on a cup of carriage zakontrogaen native ring from the cup.

Rear hub is used as an intermediate shaft h4> Installed in U - shaped segment proftruby.

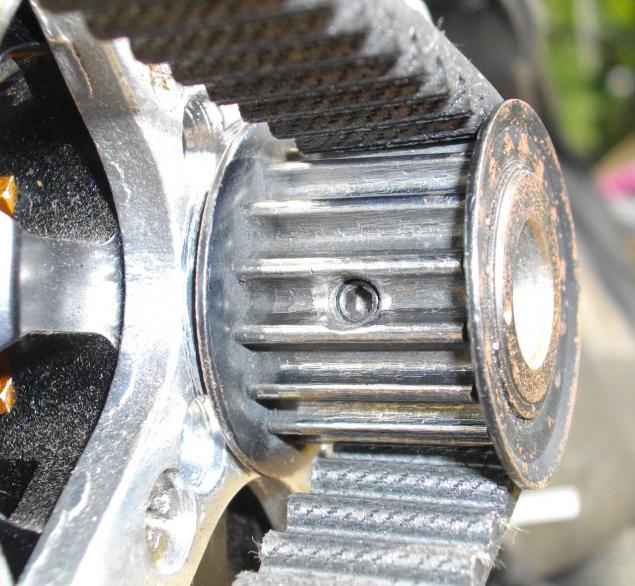

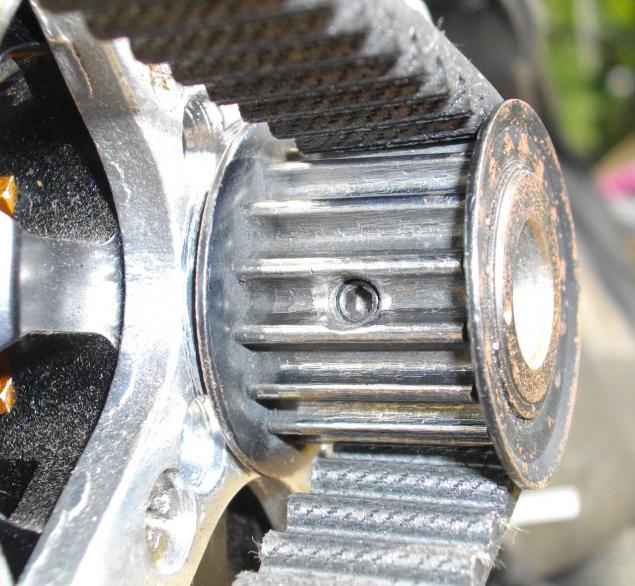

Large gear h4> secure from turning on the shaft of the pin, without the sleeve itself "pinched" cones.

pinion h4> Fixed to the motor shaft 2 Goujon.

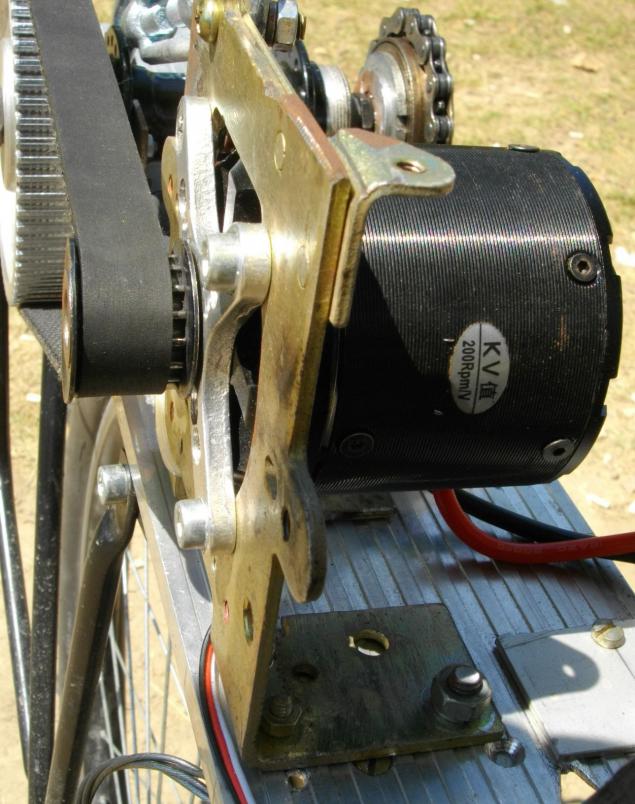

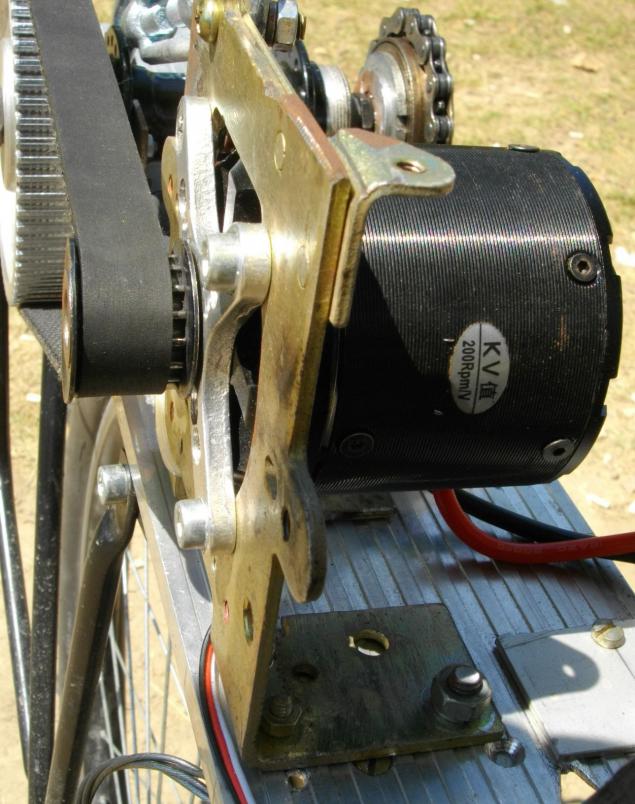

Motor h4> Fits standard crosspiece of the L shaped structure found in the bins.

chain tensioner h4> is fixed to the marginalia from the trunk.

A general view h4>

For the most attentive h4> Why then lanyard.

On the wiring diagram h4> The servotestere has been removed and a variable resistor is connected instead of the Hall sensor throttle.

What was the result h4> Total reduction - small gear 15 / large gear frivill 72 * 15/50 = great star 0 0625

Proof h4> I tried to make a video.

Conclusion h4> In general, the concept is quite viable, the positive impressions of the system. With the objective of fully cope. Because the sensorless (sensorless) engine with a natural does not pull, first we accelerate to 10-15 km / h feet, then gradually give "gas". If climbs to help electric drive legs "without straining" and maintaining a speed of about 20 km / h it turns out very economically.

Thanks h4> I want to say a big thank you to my godfather Andrew, without whom my crazy ideas would never have been implemented in the metal.

Inspired by the articles authored by chomper

«History of another electric bikes with their hands»

and «History of another electric bikes with their hands v2.0» , decided to create something of their own.

What happened, so to speak, "based on" and a lot of photos and text - under the cut.

Adherents motor-wheels I have to say - I do not want a weight of 7kg or on the front wheel or rear. I work on the third floor and the stairs to carry this charm - no really, thank you. I>

Sourcebook was taken the concept and rethought to fit your needs.

Motives built partially trivial - I want to go to work by bike, but one slide completely kills all impulses, and partly not - like their hands to feel "elektrobayk».

The basis was taken purebred bike, bought many years ago from peddlers "ad from Europe ».

From purchased: h4> Electric (model outrunner) size 6354 kv200 50,178,508

Specifications from the seller

Rotational Speed: 200 (kv) RPM / V

Continuous Current: 90A

Max. Current: 100A

Input Voltage: 14.8 - 37V

Max. Efficiency: 98%

No Load Current: 0.9A

Internal Resistance: 74m (Omega)

Power: 2450W

Motor Dimensions (Diameter x Length): 63mm x 72mm

Propeller Dimensions: 19 x 10/19 x 12 / 18.5 x 12

Input Battery Types: NiCd / Nimh / Li-po Battery

Recommend Model: Airplane

Spidkontroller (ESC) In the first version was Mystery Firedragon 80A, aka Hobbywing, aka Fentium

But it had negative results. Synchronization failures under load spoiling all the fun from the use of handheld device.

Later, it was bought by Hobbyking SS Series 90-100A

With this controller is much better if there are minor setbacks to press too hard on the gas.

Servotester is probably the easiest and most common.

Vattmetr- clone Turnigy 130A 37,273,419

battery- model LiPO 6S 22.2V 5a-h China HRB brand with current output declared 50C

Handle gas from the series electric bicycles, thumb Inside the Hall sensor with a linear output and a system of magnets on a movable ring.

Powered by 5 volts and produces about 0.7 to 4.6v.

Handles brake sensor pressing planned to make a cut-off of gas by pressing any brake, but perhaps just do the rear lights «stop»

Frivill (ratchet) 16 teeth 19,737,622

The rear trunk, as part of the design

Finish gears and belt with the profile of the tooth HTD 5M and 72 15zubov wide 15mm.

- The front sprocket used 50 teeth, I do not know of any system chosen from what it was.

- Perekidka, I used for use as a chain tensioner.

- Left cup carriage with clamping ring (locknut?)

- And of course the chain.

- An assortment of fasteners.

The old rear hub I had.

Now, construction sites h4> From attachment of spokes sprocket wheel to transmit effort was abandoned immediately.

Use standard mount for disc brake with the disc. The asterisk is bolted to the disc.

I apologize for the dusty bike.

Anticipating questions about the 2 screws between 6th mounting disc - it screws that secure the mounting thread drive from unwinding. I agree that a controversial decision, but it still works.

Yes, nature is where the rear hub mounting disk is integral with the sleeve and then would not have to use the "match and acorns." But in certain circumstances, it had to do so.

Frivill (ratchet) h4> Mounted on a cup of carriage zakontrogaen native ring from the cup.

Rear hub is used as an intermediate shaft h4> Installed in U - shaped segment proftruby.

Large gear h4> secure from turning on the shaft of the pin, without the sleeve itself "pinched" cones.

The gear milled groove in the shaft drilled and inserted pin that fits into a groove in the wheel.

pinion h4> Fixed to the motor shaft 2 Goujon.

Motor h4> Fits standard crosspiece of the L shaped structure found in the bins.

chain tensioner h4> is fixed to the marginalia from the trunk.

All mounted on a structured plate of rigid aluminum, which in turn is fixed to the marginalia from the trunk.

A general view h4>

For the most attentive h4> Why then lanyard.

This "spike" appeared in the process of finishing the construction. The engine torque enough to deform the carrier plate, wherein the belt tension weakens, and it slips. We solved the problem "head" now everything is normal.

On the wiring diagram h4> The servotestere has been removed and a variable resistor is connected instead of the Hall sensor throttle.

Also installed backwater 1k resistor in a circuit button, as observed without mode switching, probably due to interference.

At the moment, the scheme looks like.

In order not to pull the power wires through the bike, have imposed power meter shunt as described from this website .

Well spaced & quot; + & quot; Food and & quot; + & quot; measuring, put in perspective isolated converter 9V to 5V (are found in the network card with BNC) as in the current scheme, there is still some evidence of under-current.

Battery operated without a BMS, used to prevent overdischarge battery monitor tuned to 3.3 V. On reaching the set voltage or less well-read on any bank very loud squeak.

I charge IMAX B6 clone mode Li-Io-balanced. Why not Li-Po? Because the charge to 4.1 volts instead of 4.2 should theoretically increase the battery life.

What was the result h4> Total reduction - small gear 15 / large gear frivill 72 * 15/50 = great star 0 0625

The maximum engine speed at the rated voltage of the battery 22.2 * 200 = 4440

After reduction * 4440 0, 0625 = 277, 5 / min to a wheel.

With a diameter of wheels 650mm (under load rider will let 640) the theoretical speed of 33 turns, 477 km / h

In practice, in a straight line on a slight slope fixed rate of 33.3, which is close to the theory.

Energy consumption - peak consumption (indication power meter, and they can be a little "parrots") 1200vatt

Average consumption with rapid uphill with a slight slope of 600-800 watts. By direct 100-300 watts.

Proof h4> I tried to make a video.

In view of the road and shooting "with hands" video came out so-so, but something you can consider. For the general impression has cut staff - beginning slides , about 8-я second video 27th , when it was the maximum current consumption. The rise of the hill without legs only on the electric motor at the maximum "gas", slope slides do not know the details for those wishing to route with guglokart.

Another video, motion in a straight line, at the end of a small acceleration (to catch the green), route .

Conclusion h4> In general, the concept is quite viable, the positive impressions of the system. With the objective of fully cope. Because the sensorless (sensorless) engine with a natural does not pull, first we accelerate to 10-15 km / h feet, then gradually give "gas". If climbs to help electric drive legs "without straining" and maintaining a speed of about 20 km / h it turns out very economically.

The plans to increase the capacity of the battery, install the casing on the drive to clean up the electrical parts.

Thanks h4> I want to say a big thank you to my godfather Andrew, without whom my crazy ideas would never have been implemented in the metal.

Source: habrahabr.ru/post/229885/

40 best games for Android (for now)

Using the principles of Gestalt psychology to increase conversion sites. Part 1: The law of brevity